1.5mm Smooth Impermeable HDPE Geomembrane

Introducing Haoyang Environmental Co., Ltd., a leading innovator in environmental solutions since 2008. With a steadfast commitment to excellence, we specialize in a diverse range of services, including geosynthetic material research and development, environmental engineering consulting, and comprehensive solid waste treatment.

At the heart of our offerings lies the 1.5mm Smooth Impermeable HDPE Geomembrane, a testament to our dedication to cutting-edge technology and sustainable practices. This high-density polyethylene geomembrane stands as a pinnacle of quality and reliability in environmental protection.

Geomembrane Introduction

Geomembrane is a polymer film used in engineering and environmental applications, typically made from plastic materials such as polyethylene (HDPE), etc. It has the functions of waterproofing, impermeability, isolation and protection, and is widely used in various engineering projects and environmental protection.

Geomembrane plays an important role in the field of environmental protection and basic engineering, and can effectively improve the stability of engineering structures and protect the environment. Choosing the right material and correct construction method is crucial for geomembrane to play the best role.

Haoyang Environment is a professional supplier of geomembrane, with the country's largest radius of geomembrane production equipment and a variety of production lines, is one of the main suppliers of China's South-to-North water diversion project.

HDPE Geomembrane Construction Process Requirements

(1) The construction process of HDPE impervious film should be carried out in the following order: impervious film laying → matching weld → welding → field detection → repair → reinspection → backfill

(2) The seam lap width between the film and the film is 100-150mm.

(3) When laying HDPE impermeable film, the appropriate amount of expansion deformation should be reserved according to the local temperature change amplitude and foundation firmness and the performance requirements of HDPE impermeable film.

(4) After the HDPE impermeable film is laid, walking on the film surface and carrying tools should be minimized.

(5) Laying HDPE impermeable film, before the protective layer is not covered, 20-40Kg sandbags should be placed at the edge of the film every 2-5m to prevent the impermeable film from being blown by the wind.

(6) HDPE impermeable film should be natural, have a support layer, should not be folded, hanging.

(7) When the impervious membrane is constructed in sections, the upper layer should be covered in time after installation, and the time of exposure to the air should not exceed 30 days.

Advantages

Here's why our 1.5mm Smooth Impermeable HDPE Geomembrane stands out:

Impermeable Barrier: Engineered with precision, our geomembrane offers unparalleled impermeability, ensuring effective containment of liquids and gases in various environmental applications.

Robust Construction: Crafted with the highest-grade materials, our geomembrane boasts exceptional strength and durability, capable of withstanding challenging environmental conditions for extended periods.

Versatile Applications: From soil remediation to hazardous waste containment, our geomembrane serves as a versatile solution for diverse environmental challenges, meeting the rigorous demands of modern environmental engineering projects.

Stringent Quality Assurance: Committed to quality excellence, our manufacturing processes adhere to stringent standards, including ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring consistency and reliability in every product.

Innovative Research and Development: Backed by a team of dedicated professionals and extensive research facilities, we continuously innovate and refine our products, staying at the forefront of environmental technology.

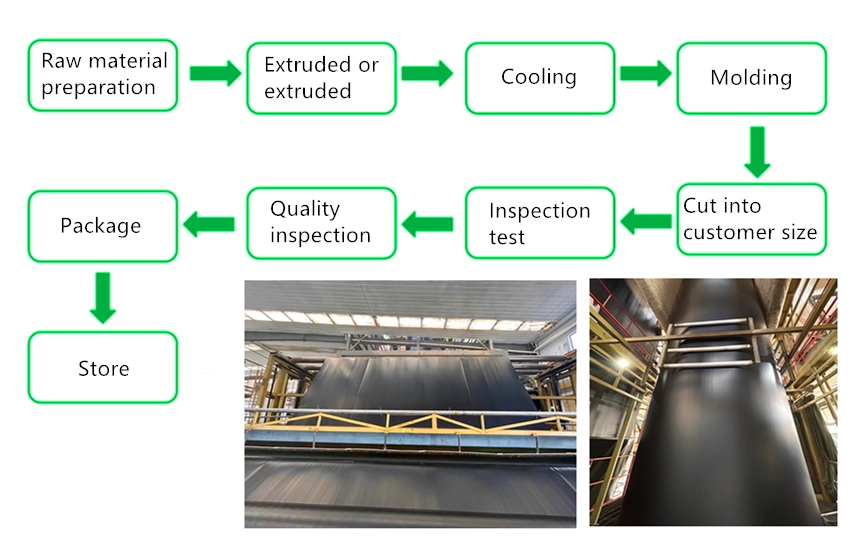

How is Geomembrane Produced?

Geomembrane is formed through the extrusion production process, the specific steps are as follows:

First of all, raw material preparation: according to the required characteristics of the geomembrane, select high-quality polymer resins, such as polyethylene (HDPE), etc. Different masterbatches can be added to harmonize the color of the geomembrane.

Secondly, extrusion: the selected polymer resin is heated and melted in the extruder. The molten polymer is then pushed into the mold to form a continuous sheet or film.

The third is calendering or rolling: the extruded sheet is pressed through a roller to smooth the material, ensuring uniform thickness and surface finish.

The fourth is cooling and solidification: the flat sheet is cooled by cooling rollers or water baths. This rapid cooling process solidifies the polymer into a stable geodiaphragm.

The fifth is testing and quality control: the geomembrane is inspected for quality and tested for parameters such as thickness, tensile strength, tear resistance and flexibility to ensure that it meets industry standards and specifications.

The sixth is finishing: geomembrane can be processed through additional surface texturing or surface treatment processes to improve specific performance characteristics if required for certain applications. The geomembrane of Haoyang environment can make single or double rough surface.

Finally, cutting and packaging: once the quality check is passed, the geomembrane is cut to the desired size, rolled into large scrolls or folded into specific sizes, packaged and shipped to the end user or stored. Haoyang environment has a complete testing center, each batch of products must go through strict testing before shipping.

The production of geomembranes involves precise control of temperature, pressure and quality checks throughout the manufacturing process to ensure consistency and compliance with standards.

Factory Display

Welcome to the geomembrane production workshop of Haoyang Environment! It is a modern production site that combines advanced technology and innovative ideas. We have the largest radius of geomemofilm production equipment in the production process shows its unique advantages, perfectly meet the needs of customers, efficient extrusion machine with its precise temperature control and stable production speed, to ensure the uniformity and thickness accuracy of geomemofilm. At the same time, the advanced cooling system ensures the rapid solidification of the film, ensuring the quality and stable performance of the product.

This production workshop not only has superior equipment, more experienced team. Our staff are professionally trained and constantly explore innovative production methods to ensure that our geomembranes are always at the leading level in the industry.

Common HDPE Geomembrane (GH-1 type) Technical Performance Index GBT17643-2011

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

Product Application

Geomembrane has a wide range of application fields, mainly including but not limited to the following aspects:

(1)Waterproof works: Waterproof barriers for all kinds of engineering projects, such as basements, tunnels, reservoirs, river embankments and water conservancy projects, effectively prevent water penetration and leakage.

(2)Soil isolation: Used to isolate different soil layers or to stop contaminants from seeping into groundwater, such as in landfills, chemical plants, and wastewater treatment facilities.

(3)Soil stabilization and reinforcement: Used for the reinforcement and stabilization of soil, used in roads, railways, airports, retaining walls and land backfill and other engineering projects to enhance the stability and bearing capacity of the structure.

(4)Environmental protection: Used for environmental remediation and protection works to close or isolate contaminated land areas to prevent the spread of pollutants.

(5)Hydraulic engineering: In coastal protection, DAMS, water channels and artificial islands and other hydraulic engineering, to prevent water infiltration and erosion.

(6)Landscape design: Applied in landscape and landscape design as ground cover material, protect soil and vegetation, control water penetration.

(7)Mining and industrial applications: Used in mines, chemical plants and industrial facilities as an impermeable layer to prevent waste or harmful substances from leaking and protect the environment.

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

Partner with Haoyang

Partner with Haoyang Environmental Co., Ltd. and experience the difference that our 1.5mm Smooth Impermeable HDPE Geomembrane can make in your environmental projects. Together, let's build a sustainable future for generations to come.

FAQ

Q1: What is the lead time?

A1: Usually 5-10 working days after receiving the deposit.

Q2: Can you produce according to the customer's requirements?

A2: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q3: How do you guarantee the quality testing of your products?

A3: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q4: What is the main material of this geomembrane?

A4: Our geomembranes are usually made of plastic materials such as polyethylene (HDPE).

Q5: What are its main uses?

A5: Mainly used in soil separation, drainage, waterproofing, protection and other projects to prevent soil erosion and protect infrastructure.

Q6: What are the specifications and sizes of this geomembrane?

A6: Geomembrane has good weather resistance and chemical resistance, and can be used stably for a long time under a variety of environmental conditions.

Q7: What should I pay attention to in terms of installation and use?

A7: We offer competitive prices and guarantee that our products meet quality standards to ensure that our customers receive high quality products.

Q8: Is this geomembrane environmentally friendly?

A8: Geomembranes are often manufactured from recycled materials, meet environmental standards, and remain stable after use

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1mm Single-texture HDPE geomembrane.pdf

1mm Single-texture HDPE geomembrane.pdf

![]() 2mm Single-texture HDPE geomembrane.pdf

2mm Single-texture HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

503.webp)

759.webp)

942.webp)

237.webp)

106.webp)