Geosynthetic Clay Liner (GCL), also known as Bentomat or geosynthetic clay composite, is a type of geosynthetic material used in various civil engineering and environmental applications, primarily for containment and lining systems. It consists of a thin layer of natural sodium bentonite clay sandwiched between two geotextile or geomembrane layers.

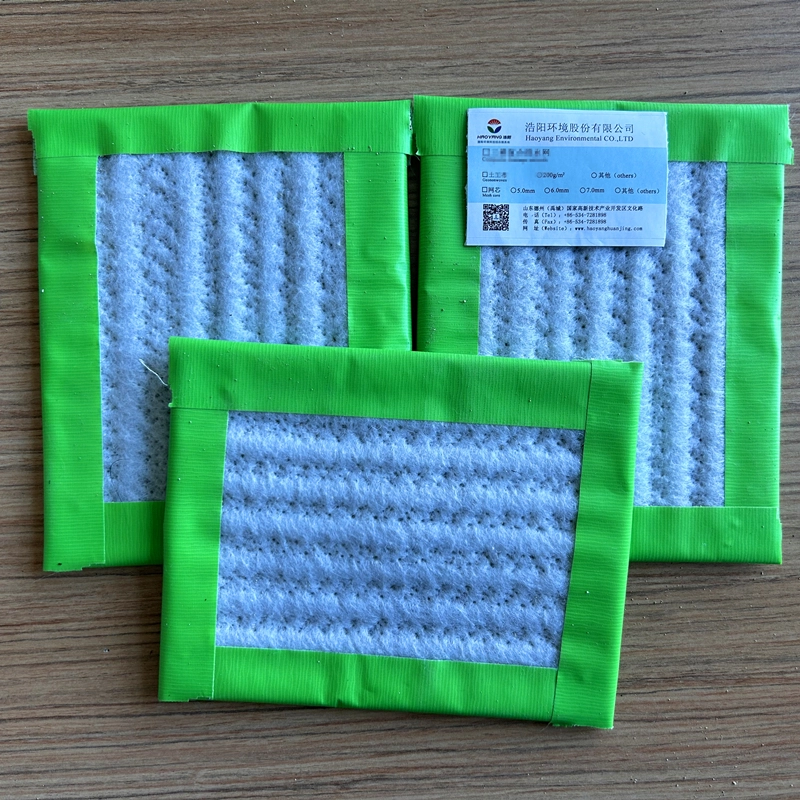

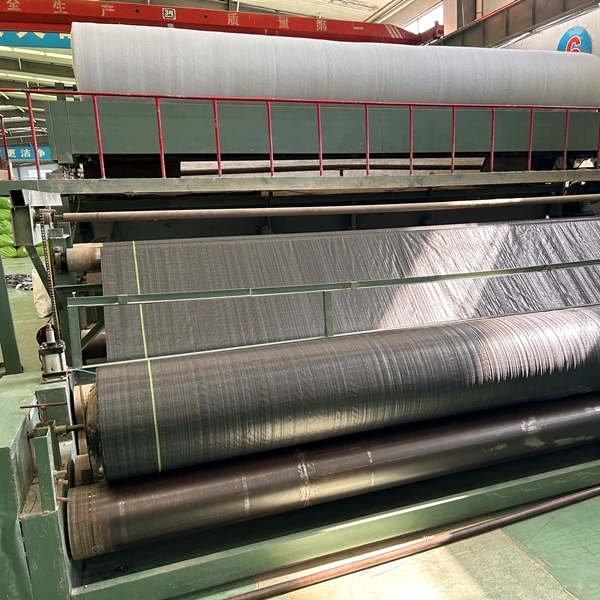

We are a famous Geosynthetic Clay Liner (GCL) manufacturer and suppler in China. Our factory has 3 production lines dedicated to the production of GCL. Next we will learn more about GCL.

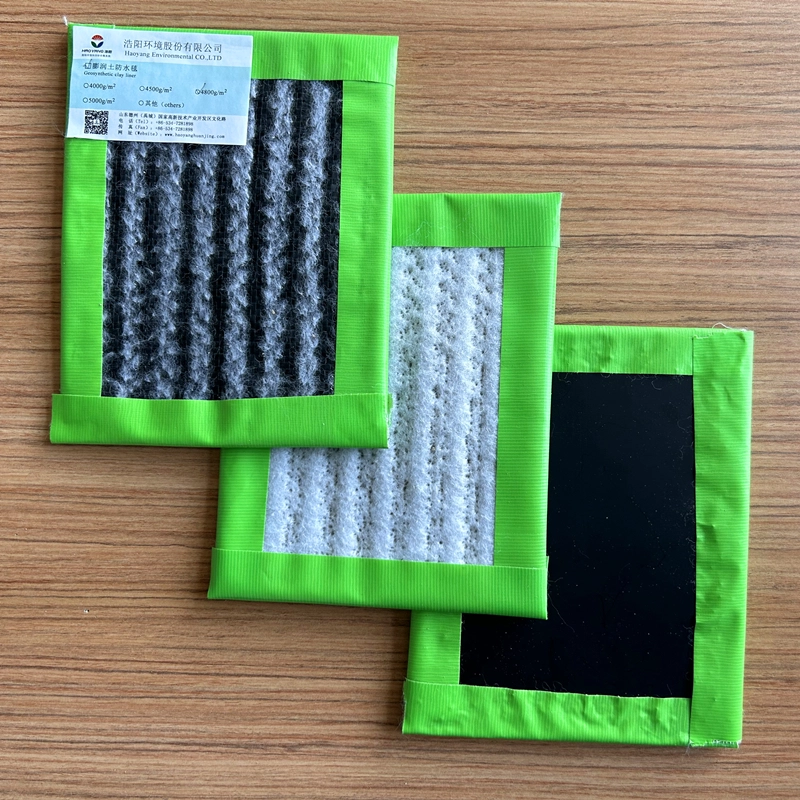

The components of a typical Geosynthetic Clay Liner (GCL) include:

Sodium Bentonite Clay: This is the key component of GCLs. Bentonite is a naturally occurring clay material with highly absorbent and swelling properties. The clay's ability to swell and form a tight, impermeable barrier upon contact with water is utilized in GCLs to create a waterproof layer.

Geotextile or Geomembrane Layers: The bentonite clay is encapsulated between two layers of geotextile or geomembrane materials. These layers serve multiple purposes:

Provide mechanical support to the clay layer.

Prevent the loss of bentonite due to erosion or displacement.

Enhance the structural stability of the liner.

Offer protection against puncture or damage.

Geosynthetic Clay Liners (GCLs) are commonly used in various applications, including:

Landfill Liners and Caps: GCLs are employed as part of composite liners in landfills to contain and prevent the migration of leachate into the surrounding soil and groundwater. They act as a barrier to protect the environment from potential contamination.

Wastewater Treatment: GCLs are utilized in the construction of ponds, lagoons, and other containment structures in wastewater treatment facilities to prevent seepage and leakage.

Mining and Containment: They are used in mining applications, such as tailings dams and heap leach pads, to contain and control the flow of potentially hazardous materials.

Waterproofing: GCLs are also utilized in civil engineering projects for waterproofing applications, such as lining for canals, reservoirs, and tunnels, to prevent water seepage.

Geosynthetic Clay Liners offer advantages such as ease of installation, good hydraulic performance, and environmental compatibility. However, their effectiveness relies on proper installation techniques and adherence to design specifications to ensure optimal performance in various engineering and environmental protection applications.

Download

![]() Geosynthetic_Clay_Liner_GCL.pptx

Geosynthetic_Clay_Liner_GCL.pptx

Hot Search

- geomembrane

- Geotextile

- Geosynthetics

- GCL

- geofabrics

- geosynthetic clay liners

- China

- geosynthetic clay liner

- Waterproof

- GCLs

- Geosynthetic

- geocomposites

- bentonite waterproof blanket

- specifications

- geosythetic caly liner

- geosynthetic clay liner price

- Sodium bentonite waterproof blanket

- Corrosion resistance

- landfill liner

- landfill liner material

- Phosphogypsum slag storehouse

- bentonite waterproof blanket(Geosynthetic Clay Liner GCL)

- Production

- sodium bentonite GCL

- Domestic waste landfill

- sell landfill liner material

- GCL factory low price

- landfill liner material GCL

- Purpose

- bentonite waterproof blanket effective measure

855.webp)

161.webp)

927.webp)

109.webp)

693.webp)

717.webp)

336.webp)

158.webp)

306.webp)