Haoyang: A Leading Enterprise in the Production of Filament Nonwoven Geotextile

At Haoyang Environmental Co., Ltd., we are committed to providing our customers with the highest quality filament nonwoven geotextile products. Our unique production process and exquisite craftsmanship ensure that every roll of filament nonwoven geotextile meets the highest quality standards.

Advantages

We strictly control the raw material procurement process, selecting the highest quality polyester particles to ensure that the produced filament nonwoven geotextiles have excellent performance. Through precise spinning processes, we form continuous filaments, which are then woven and treated with cooling, stretching, and other processes to obtain fibers with certain strength and extensibility. The raw materials can also be switched according to your needs, such as PET, PP, PA, PE.

In the pre-processing step, we perform fine processing on the fibers, including removing impurities and increasing fiber surface activity, to ensure that each fiber is in optimal condition. Next, we use advanced coating technology to coat a layer of chemical materials on the fiber surface to improve the corrosion resistance, aging resistance and water permeability of filament nonwoven geotextile.

After precise winding and packaging processes, we wind the coated filament nonwoven geotextile into rolls and professionally package them. During the quality inspection process, we conduct rigorous testing on the appearance, size, performance, and other aspects of each roll of filament nonwoven geotextile to ensure that the product meets customer requirements. Finally, we perform final packaging on the qualified products and arrange for shipment to ensure that the products are delivered to customers in a timely manner.

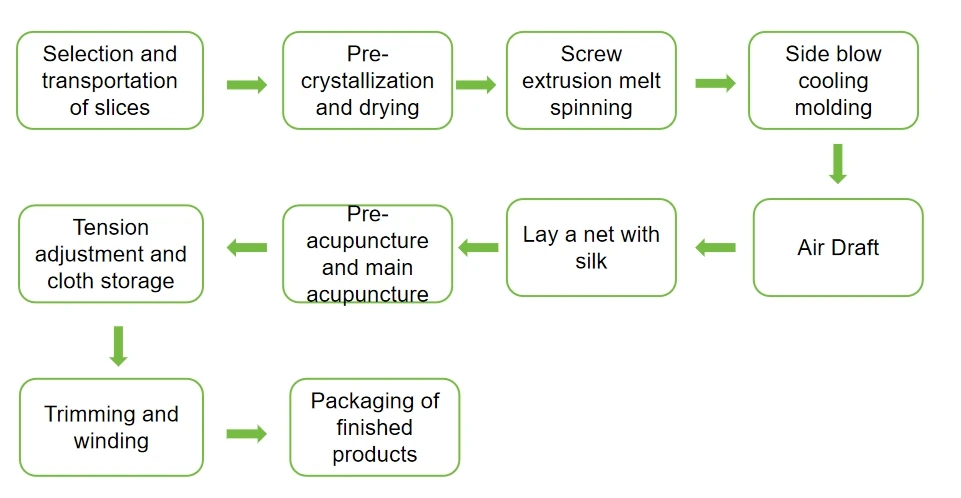

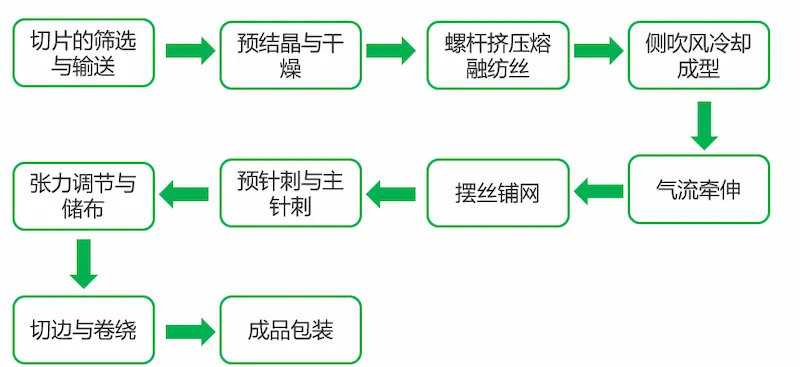

Production Process of Filament Nonwoven Geotextiles

The specific production process of filament nonwoven geotextiles is as follows:

1.Raw material procurement: The raw material of filament nonwoven geotextile is mainly polyester particles. The raw materials can also be switched according to your needs, such as PET, PP, PA, PE.

2.Spinning: Polyester particles are melted, filtered, and extruded to form continuous filaments.

3.Weaving: The filaments are cooled, stretched, and processed to obtain fibers with certain strength and elongation.

4.Pre-treatment: Pre-treatment of fibers, including removing impurities and increasing fiber surface activity.

5.Coating: A layer of chemical material is coated on the fiber surface to improve the corrosion resistance, aging resistance, and water permeability of filament nonwoven geotextiles.

6.Winding and packaging: The coated long-fiber geotextile is wound into rolls and packaged.

7.Quality inspection: Quality inspection of filament nonwoven geotextiles, including appearance, size, and performance testing.

8.Packaging and shipment: The qualified products are packaged and arranged for shipment.

Join Us

Hao Yang Environmental Co., Ltd. has won the trust of its customers with its excellent production process and strict quality control standards for filament nonwoven geotextile. Our products are widely used in various fields such as water conservancy, highway, railway, and construction, providing strong support for environmental protection and engineering construction.

Choosing Haoyang Environmental Co., Ltd., you will receive the highest quality filament nonwoven geotextile products and services. We always adhere to customer-centricity, survive by quality, and promote development through innovation. Let's work together to create a better future! Contact us now!

597.webp)

411.webp)