What is a 3D Composite Drainage Net?

A 3D composite drainage net is a geosynthetic material that combines a drainage core with geotextile layers. The core is typically a three-dimensional structure made of high-density polyethylene (HDPE), designed to provide efficient drainage while supporting loads. The geotextile layers, often nonwoven or woven, act as filters to prevent soil particles from clogging the drainage system.

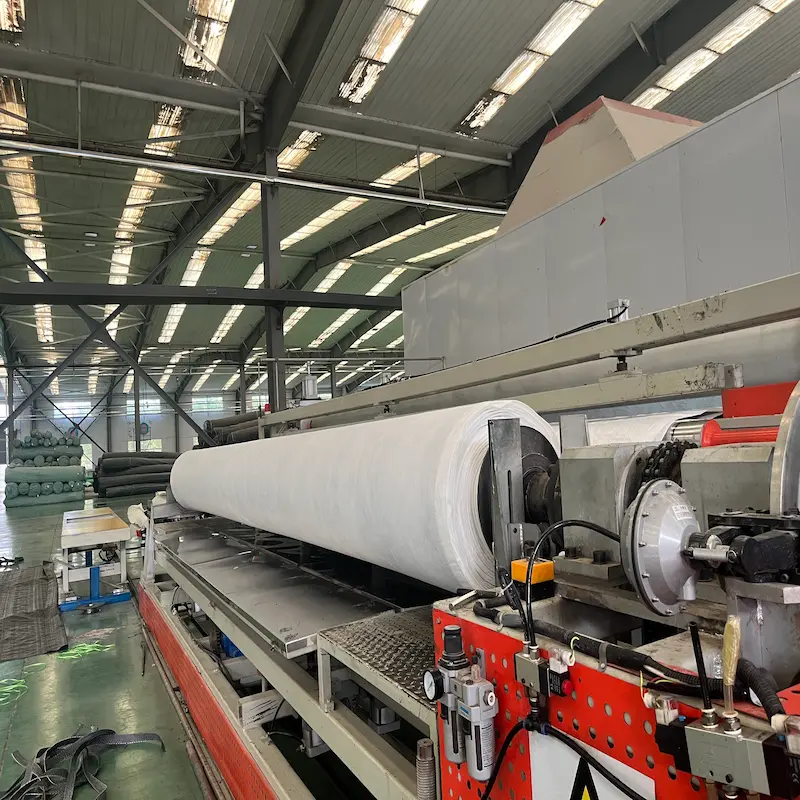

Manufacturing Process of 3D Composite Drainage Net

The production of three-dimensional composite drainage nets involves several crucial steps to ensure the material’s efficiency, durability, and compliance with industry standards.

1. Extrusion of Core Material:

The process begins with the extrusion of a polymer, most commonly HDPE, into a three-dimensional grid. The extruded polymer is heated to a high temperature and forced through a mold that shapes it into a unique grid pattern. This structure allows water to flow freely through the material while providing high compressive strength to withstand heavy loads.

2. Lamination of Geotextile:

After the core is formed, non-woven geotextiles are laminated to one or both sides of the grid using heat or adhesives. The geotextile layers help filter the water passing through the net, preventing fine soil particles from clogging the drainage system. The geotextiles are chosen for their ability to separate soil and aggregate particles while still allowing water to pass through effectively.

3. Cooling and Shaping:

The composite material is then cooled and cut into standard lengths and widths, typically in rolls. The rolls are compact and lightweight, making them easy to transport and install on-site.

4. Quality Control and Testing:

Before the drainage nets are shipped, they undergo a series of tests to ensure their performance meets international standards, such as ASTM and ISO certifications. Tests typically include evaluations of flow rate, compressive strength, UV resistance, and durability against harsh environmental conditions.

Specifications of 3D Composite Drainage Nets

3D composite drainage nets are available in various configurations to meet different project requirements. Below are common specifications:

Core Thickness | The core thickness typically ranges from 5mm to 12mm, depending on the desired drainage capacity and load-bearing strength. |

Width | The width of the drainage net can range from 2 meters to 4 meters. Some custom sizes may also be available for specialized projects. |

Roll Length | The length of each roll typically varies between 20 meters to 50 meters. Larger projects may require longer rolls, though customized sizes are often available. |

Weight | The weight of the non-woven geotextile can range from 150g/m² to 300g/m², depending on the level of filtration required for the project. |

Geotextile Types | Non-woven (150g/m² to 300g/m²) |

Flow Rate | 2.5 L/m·s to 5.0 L/m·s |

Compression Strength | 200 kPa to 400 kPa |

UV Resistance | UV resistance is an essential property for outdoor applications, as exposure to sunlight can degrade the material over time. Most drainage nets are manufactured with UV-stabilized materials to prevent degradation and maintain long-term durability. |

Custom sizes and configurations can also be manufactured based on specific project needs.

Prices of 3D Composite Drainage Nets

The price of three-dimensional composite drainage nets depends on various factors such as the material type, thickness, width, length, and custom specifications. Additionally, pricing can vary based on location, quantity, and shipping fees.

Here is a general pricing range:

Standard Rolls (2m x 30m): The cost typically ranges from $2.0 to $4.5 per square meter.

Custom Rolls (with thicker geotextiles or specialized features): The price can go up to $3.5 to $6.5 per square meter.

Bulk Discounts: Large orders or repeat customers can often receive volume discounts, reducing the per-square-meter cost.

Shipping Costs: Shipping prices are influenced by factors like distance, weight, and the logistics provider.

For specific pricing, it’s always best to contact the manufacturer or supplier directly, especially for bulk orders or specialized needs.

Pros and Cons of 3D Composite Drainage Nets:

Pros:

High Drainage Efficiency: The three-dimensional structure provides excellent water discharge capacity, even under high loads. This is particularly beneficial in situations with heavy rainfall or substantial groundwater flow.

Structural Stability: The layered design enhances mechanical strength, ensuring long-term performance under high-pressure conditions.

Lightweight and Easy Installation: Composite drainage nets are relatively lightweight and flexible, making them easy to transport and install compared to traditional drainage systems.

Durability: Made of high-quality polymers, these materials are resistant to chemicals, corrosion, and biological degradation, ensuring long-lasting performance.

Versatility: Suitable for a wide range of applications, including landfills, retaining walls, tunnels, and roadbeds, due to their adaptable and robust design.

Environmentally Friendly: Reduces the need for natural drainage materials like gravel, minimizing environmental impact.

Cons:

Cost: The initial cost of composite drainage nets can be higher than traditional drainage methods, particularly for large-scale projects.

Clogging Potential: Over time, fine particles or debris can infiltrate and block the drainage pathways, reducing efficiency.

UV Sensitivity: Prolonged exposure to sunlight can degrade some materials, necessitating proper protection during installation and use.

Limited Load Tolerance: In extremely high-load applications, such as heavy industrial uses, the material may deform or compress, compromising its drainage capacity.

Specialized Installation Requirements: Proper installation techniques are essential to ensure optimal performance, requiring trained personnel and specific equipment.

Applications of 3D Composite Drainage Nets

Three-dimensional composite drainage nets have a wide array of applications in civil engineering, environmental management, and construction. Some of the most common applications include:

1. Landfill Drainage:

In landfill construction, it is crucial to manage leachate (liquid waste) and prevent its seepage into surrounding soil and groundwater. Three-dimensional drainage nets are used in landfill base and side slopes to promote leachate drainage, helping prevent contamination.

2. Road and Railway Construction:

Water accumulation in road and railway subgrades can lead to instability, frost heave, and erosion. The drainage nets provide effective drainage, maintaining the integrity of the soil beneath and ensuring the long-term stability of roads and railways.

3. Slope Stabilization and Erosion Control:

For slopes prone to erosion, the drainage net offers a dual function: it helps drain excess water from the slope while also providing support to prevent soil displacement and erosion.

4. Retaining Walls:

Retaining walls are often used in areas with steep terrain to prevent soil movement. By installing three-dimensional drainage nets behind the wall, engineers can manage water pressure and reduce the risk of hydrostatic pressure buildup, which can lead to wall failure.

5. Green Roofs and Landscaping:

Green roofs rely on proper drainage to support plant life while preventing water accumulation that could damage the structure. The drainage net facilitates efficient water flow while retaining moisture for plant roots, helping maintain a healthy green roof ecosystem.

6. Tunnel and Underground Structures:

Water seepage into tunnels and underground structures can create severe safety hazards and damage. The use of drainage nets in these structures helps to divert water and maintain a dry and safe environment.

7. Agriculture and Landscaping:

In landscaping and agricultural applications, 3D composite drainage nets are used to manage water flow in garden beds, prevent waterlogging, and support plant growth by maintaining optimal moisture levels.

Conclusion

3D composite drainage nets are a revolutionary product that combines the benefits of drainage, filtration, and soil stabilization into a single solution. Their efficiency, durability, and versatility make them an indispensable tool in modern civil engineering and environmental management. Whether you're dealing with road construction, landfill management, or landscaping, the use of 3D drainage nets can ensure long-term stability and effective water management. By understanding the specifications, production process,prices and applications of these nets, you can make informed decisions about their use in your next project. For pricing information or technical assistance, feel free to contact us to explore customized solutions tailored to your needs.

897.webp)

942.webp)

237.webp)