What is textured geomembrane?

textured geomembrane is a new type of engineering anti-seepage geosynthetics, generally using high-density polyethylene or polypropylene as raw materials, refined by specialized production equipment and special production process. textured geomembrane can be designed and manufactured into a single or double textured surface, called single textured, double textured geomembrane, textured geomembrane can greatly improve the coefficient of friction, to maximize the effective volume of geomembrane, more suitable for steep slope and vertical engineering seepage and enhancement, the edge is smooth, in order to achieve high quality hot melt welding.

The following is a detailed introduction of the textured geomembrane:

Material characteristics

Anti-seepage ability: textured geomembrane has excellent anti-seepage performance, its anti-seepage coefficient K is less than 1.010 ^ -13g · cm / ccm ² · s · pa, can effectively prevent water leakage into other areas through the isolation layer.

Durability: textured geomembrane is made of high density polyethylene, low density polyethylene and other materials, with good corrosion resistance, aging resistance, strong toughness and other characteristics, to ensure the durability of the service life of materials.

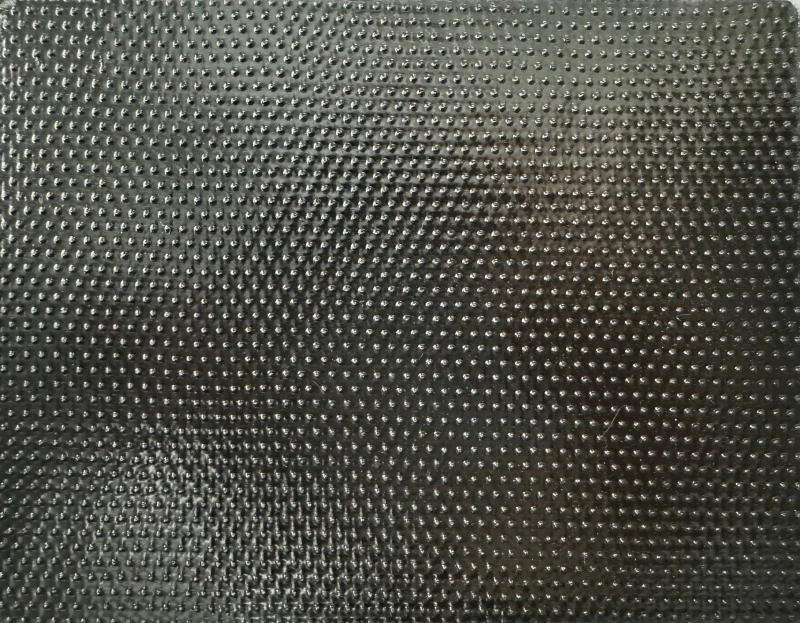

rough design: the surface of rough geomembrane has rough stone pattern, which can increase the area combined with the soil, enhance the adhesion between the foundation and the soil, and prevent the water in the soil from leaking through the isolation layer. At the same time, the textured design can also increase the friction coefficient and improve the stability of the slope.

Application advantage

Improve the seepage prevention effect: textured geomembrane slows down the penetration rate of groundwater through friction, so as to achieve better seepage prevention effect.

Infrastructure requirements are reduced: rough geomembrane can form a certain textured effect on the soil surface of the bottom of the reservoir, better attach the soil, avoid being washed or stripped by water, and reduce the requirements on the bottom of the reservoir infrastructure.

Long service life: rough geomembrane can effectively avoid the damage of the traditional geomembrane caused by the bottom of the conventional road, prolong the service life of geomembrane.

To sum up, the rough geomembrane has a wide application prospect in water conservancy, environmental protection, transportation and other fields with its excellent seepage performance, durability and rough design.

Application area

1. Water conservancy projects:

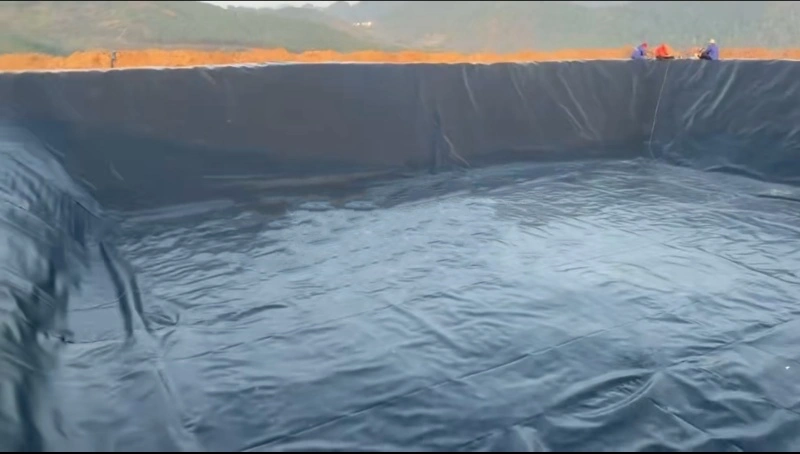

The seepage control layer of reservoirs, DAMS and embankments: the textured geomembrane can effectively prevent the leakage of water bodies and ensure the safe operation of water conservancy projects.

Anti-seepage of channels and water pipes: textured geomembrane can be used for the bottom and side walls of channels and water pipes to prevent water erosion and leakage.

2. Environmental protection engineering:

Landfill: the rough geomembrane serves as the bottom and side isolation layer of the landfill to effectively prevent the pollution of landfill leachate to soil and groundwater.

Wastewater treatment tank: In wastewater treatment facilities, rough geomembrane is used to isolate and treat wastewater to ensure environmental safety.

Tailings pond: In the construction of tailings pond, the textured geomembrane can prevent the leakage and diffusion of tailings and protect the environment.

3. Traffic engineering:

Roadgrade protection of highway and railway: the textured geomembrane can be used as the water barrier layer and anti-skid layer of the subgrade to enhance the stability and bearing capacity of the foundation.

Waterproofing of tunnel and underground engineering: in tunnel and underground engineering, textured geomembrane can be used for waterproof isolation layer to prevent groundwater penetration.

4. Landscape aspects:

Bottom and side walls of artificial lakes, ponds and pools: textured geomembrane provides seepage and isolation functions to ensure the durability and aesthetics of water.

Construction of waterfalls, streams and waterscape: the textured geomembrane is used at the bottom and side of the waterscape to create a natural flow effect.

5. Mining engineering:

Tailings dam: textured geomembrane can be used for the seepage layer of tailings dam to prevent tailings leakage caused by environmental pollution.

Pit backfill: During the pit backfill process, the rough geomembrane can prevent moisture infiltration and pollution in the backfill material.

6. Agriculture:

Reservoir and irrigation channel: textured geomembrane can be used for the seepage prevention of agricultural reservoir and irrigation channel, and improve the utilization efficiency of water resources.

Bottom of greenhouse and breeding pond: textured geomembrane can be used at the bottom of greenhouse and breeding pond to prevent water leakage and pollution.

7. Other areas:

Environmental protection bags and packaging bags: textured geomembrane can be used to make environmental protection bags and packaging bags, with good waterproof and seepage prevention performance.

Waterproof engineering: textured geomembrane can also be used for building basement, roof, bathroom and other waterproof engineering.

In short, the rough geomembrane, with its excellent seepage prevention performance and rough design characteristics, has a wide range of applications in water conservancy engineering, environmental protection engineering, traffic engineering, landscape, mining engineering, agriculture and many other fields.

Production engineering

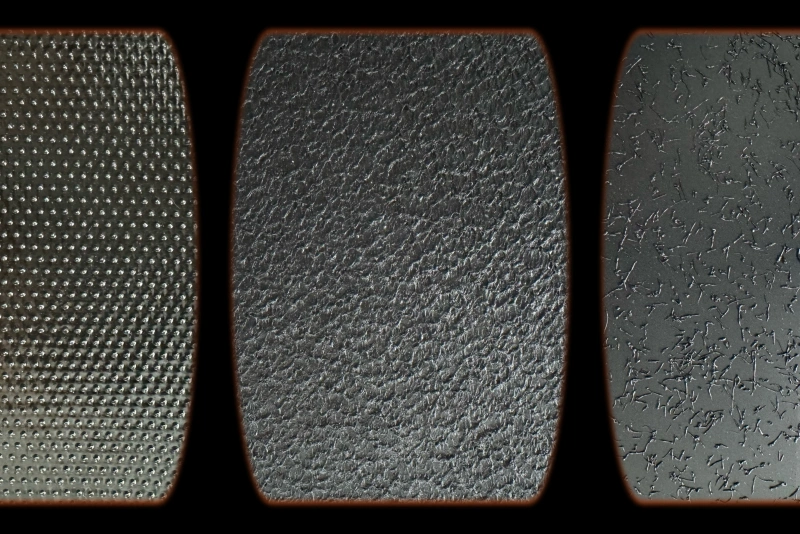

Nitrogen foaming textured geomembrane: replace the foaming agent with nitrogen and directly mix with PE geomembrane raw materials, after mixing with the ordinary layer of PE geomembrane raw materials together into the multilayer coextrusion mold head of different flow channel, common extrusion molding. This method belongs to primary molding and is suitable for continuous production of blowing molding process.

Stagne geomembrane: PE particles are plasticized by the mold head, and formed by the press bar with regular concave surface.

Spray and coarse method: through the smooth surface surface coarse particles form textured of geomembrane, which is the only one without sacrificing the mechanical properties and structural integrity of the base film produced rough geomembrane coarse process, so to the greatest extent retained the physical and mechanical tensile properties.

Size of product

Thickness: The thickness of the textured geomembrane is usually between 1.0mm and 3.0mm, with the larger dosage of 1.5mm and 2.0mm. This thickness range ensures that the geomembrane has sufficient strength and durability to meet various engineering needs.

Width: the width of the textured geomembrane according to the production capacity and engineering requirements, generally can produce 1 meter to 10 meters wide, can be customized according to the construction environment and project requirements.

Length: The length of the textured geomembrane is usually customized according to the engineering design and customer requirements to meet the needs of specific projects.

Color: The textured geomembrane is usually black or white, and these colors help to absorb or reflect sunlight to meet the needs of different environments and uses.

Chemical resistance: the textured geomembrane has excellent chemical resistance, can resist the erosion of various chemical substances, so as to maintain its long-term stability and service life.

Anti-skid function: the surface of the textured geomembrane after special treatment, has a large friction coefficient, with good anti-skid function. This makes rough geomembrane especially suitable for steep slope and vertical seepage prevention engineering, can improve the stability and safety of engineering.

In conclusion, the product specifications of the textured geomembrane cover the thickness, width, length, color, and chemical resistance and anti-skid function. These specifications are designed to meet various engineering needs and ensure that the textured geomembrane can achieve good seepage protection and performance in various environments.

Successful case

The textured geomembrane is used for Coal ash landfill project in South China, which effectively increases the friction between the geomembrane and the slope, and improves the stability and safety of the project.

Through reasonable construction design and strict quality control, the leakage problem has been successfully avoided, and the project has also achieved good environmental protection and social benefits.

This case fully demonstrates the excellent performance and application of rough geomembrane in the engineering project. With its excellent seepage performance and environmental characteristics, the project provides strong support for the sustainable development of the project.

High-quality Textured Geomembrane

Our company specializes in the production and export of textured geomembrane, a high-quality material widely used in various construction and environmental protection projects. With years of industry experience and cutting-edge technology, we are committed to providing our global customers with reliable and durable products that meet the most stringent standards. Our textured geomembrane is manufactured using the finest raw materials and undergoes rigorous quality control procedures to ensure its strength, flexibility, and durability. Whether it's for lining landfills, dams, reservoirs, or other civil engineering structures, our geomembrane offers superior performance and long-lasting protection.

We pride ourselves on our ability to customize our products to meet the specific needs of our clients. Our team of experts is always ready to provide consultation and support to ensure that you get the best solution for your project. At our company, we believe in building trust and long-term relationships with our customers. We are committed to providing exceptional service, competitive prices, and timely delivery. If you are interested in our textured geomembrane or have any questions, please do not hesitate to contact us. We welcome inquiries from all over the world and are excited to work with you on your next project.

897.webp)

942.webp)

237.webp)