Bentonite is a geotechnical material commonly used in civil engineering, especially in the manufacture of geosynthetic clay liners. It is an engineering material used for soil anti-seepage, consisting of alternating layers of bentonite and one or more non-woven materials. Stacked. Bentonite's high absorbency and water-repellent properties make it a key component in waterproof liners used in projects such as pools, landfills, canals, and more to prevent moisture penetration or leakage.

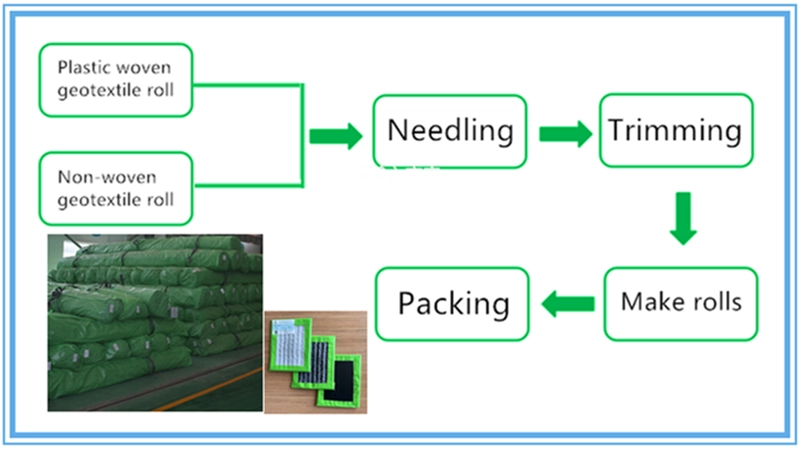

Construction process diagram of bentonite geosynthetic clay liner

To understand bentonite geosynthetic clay liners GCLs you need to know the following basic information:

1. Characteristics of bentonite: Bentonite is a clay mineral with good water absorption and plasticity. Its unique structure allows it to expand into a gel-like substance after absorbing water, forming an effective anti-seepage layer.

2. The structure of bentonite geosynthetic clay liner GCLs: It is usually composed of bentonite layers and non-woven materials (usually polymer mulch or fiber mesh) stacked alternately. This structure allows it to have the anti-seepage properties of bentonite and the strength and stability of non-woven materials.

3. Application areas: Bentonite geosynthetic clay liners GCLs are widely used in various engineering projects, such as landfills, mine tailings ponds, pools, dams and roads, etc. They can be used to prevent the infiltration of groundwater and chemicals and protect soil and groundwater resources.

4. Advantages: Compared with traditional geotechnical anti-seepage materials (such as clay or plastic film), bentonite geosynthetic clay liners GCLs have the advantages of easy installation, low cost, short construction period, and environmental friendliness. In addition, they have high anti-seepage properties and stability.

5. Construction precautions: When installing bentonite geosynthetic clay liner GCLs, it is necessary to ensure that the base is flat and clean, and appropriate technical measures are taken to ensure a tight connection between the layers to give full play to its anti-seepage effect.

Overall, bentonite geosynthetic clay liners GCLs play an important role in modern civil engineering, providing reliable anti-seepage solutions for various engineering projects.

Technical Parameter

Inspection Item | Testing Procedure | Technical Index |

Bentonite mass for unit area | ASTMD5993 | ≥5.5kg/m2 |

Expansion coefficient | ASTMD5890 | ≥ 25mL/2g |

Low temperature ductility | ASTMD5898 | No impact at -35°C |

Thickness | ASTMD5892 | ≥6.4mm |

Tensile strength | ASTMD4632 | ≥540N |

Peel strength of concrete face | ASTMD4632 | ≥3.0 KN/ m2 |

Peel strength | ASTMD4632 | ≥68N |

Indicated flow | ASTMD5887 | ≤1 × 10-8m3/m2/sec |

Hydrostatic pressure resistance | ASTMD5888 | ≥70 |

Permeability | ASTMD5887 | ≤5 × 10-12cm/sec |

Extension rate | ASTMD5896 | ≥20 |

Puncture strength | ASTMD5894 | ≥635N |

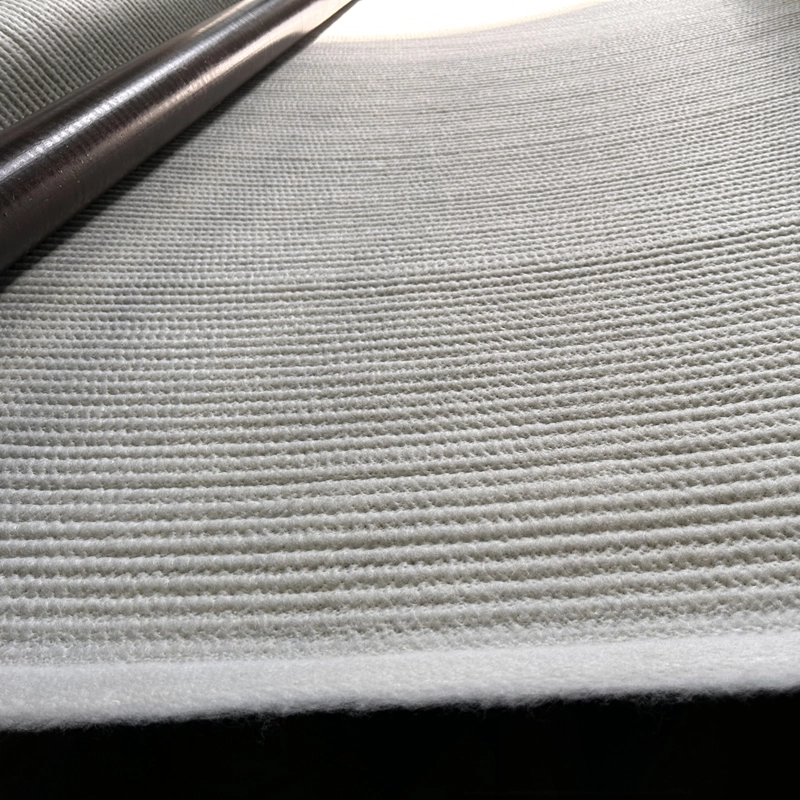

Haoyang bentonite geosynthetic clay liner production equipment is working

When it comes to bentonite geosynthetic clay liners GCLs, there are some other aspects worth noting:

1. Permeability: Bentonite has excellent permeability and can effectively prevent the penetration of moisture, chemicals and pollutants. This makes bentonite geosynthetic clay liners GCLs ideal for preventing groundwater and soil contamination.

2. Durability: Properly installed and maintained GCLs usually have a long service life and can maintain their anti-seepage properties for a long time, thereby reducing the frequency and cost of maintenance and replacement.

3. Environmentally friendly: Compared with some traditional anti-seepage materials, bentonite geosynthetic clay liner GCLs are generally more environmentally friendly. They contain no chemicals that are harmful to the environment and do not release harmful substances into the soil or water during use.

4. Coping with challenges: Although bentonite geosynthetic clay liner GCLs perform well in terms of anti-seepage, performance degradation may occur under some extreme environmental conditions, such as high temperature, extreme PH value, chemical corrosion, etc. Therefore, the characteristics of the actual engineering environment need to be taken into consideration when selecting and designing bentonite geosynthetic clay liners GCLs.

5. Continuous development: With the continuous development and innovation of civil engineering technology, the manufacturing process and performance of bentonite geosynthetic clay liners GCLs are also continuously improved and improved to meet a wider range of application needs and environmental requirements.

In general, bentonite geosynthetic clay liner GCLs, as an advanced civil engineering material, play an important role in preventing soil and water pollution, protecting the environment and human health.

Haoyang bentonite geosynthetic clay liner production process diagram

During construction, proper installation and handling are critical to ensure the performance of bentonite geosynthetic clay liners GCLs. We must pay attention to the construction aspects of bentonite geosynthetic clay liners GCLs:

1. Substrate preparation: Before installing bentonite geosynthetic clay liner GCLs, you need to ensure that the substrate surface is flat, dry, clean, and free of sharp objects or damaged surfaces. Any obstructions that may affect the performance of bentonite geosynthetic clay liners GCLs should be removed or repaired.

2. Joint treatment: Bentonite geosynthetic clay liner GCLs are usually supplied in roll form, and the joints need to be treated during the laying process to ensure continuity and sealing between the layers. It is usually processed by methods such as overlapping, welding or gluing.

3. Laying technology: When laying bentonite geosynthetic clay liner GCLs, you need to follow the specific laying instructions provided by the manufacturer to ensure a tight bond between the layers and avoid any damage or deformation. Bentonite geosynthetic clay liners GCLs are typically compacted using rolling or vibrating equipment to ensure a tight fit to the substrate.

4. Edge treatment: The edges of bentonite geosynthetic clay liners GCLs should be properly treated to ensure a tight connection with adjacent structures or ground surfaces to prevent moisture or pollutants from penetrating through the edges.

5. Quality control: During the construction process, quality control inspections are required, including inspection and testing of the laying quality, joint treatment quality, compaction conditions, etc. of bentonite geosynthetic clay liner GCLs to ensure compliance with specification requirements.

6. Protection measures: After the bentonite geosynthetic clay liner GCLs are laid, appropriate protective measures need to be taken to prevent them from being affected by external environmental factors (such as sunlight, wind, and rain) to maintain stable and durable performance.

7. Document records: After the construction is completed, the construction process should be recorded, and relevant construction documents, inspection reports and test data should be saved for future supervision and maintenance.

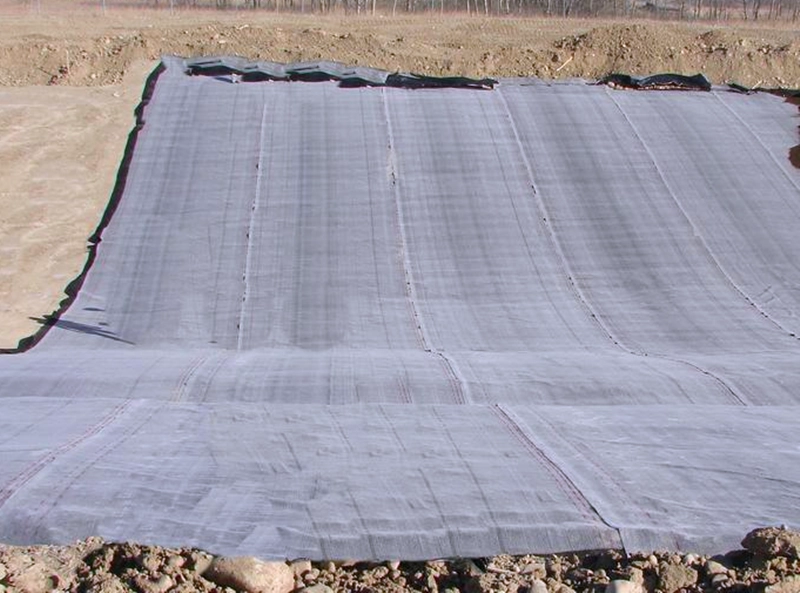

Haoyang bentonite geosynthetic clay liner laying renderings

Packaging & Shipping

Packaging Details: woven geotextile, PE film.

Delivery Detail: 5 days from order date.

Selling Units: | Single item |

Single package size: | 500X60X60 CM |

Single gross weight: | 800.0 KG |

In summary, correct construction is key to ensuring that bentonite and geosynthetic clay liners can play an effective anti-seepage role. The reliability and durability of bentonite geosynthetic clay liners GCLs in engineering projects can be ensured by following proper construction procedures and quality control standards.

503.webp)

759.webp)

855.webp)

161.webp)

927.webp)