1, Geotextile fabric for waterproofing-composite geomembrane

When people talk about geotextile fabric for waterproofing, the first product comes to their mind are usually composite geomembrane.

Composite geomembrane, also known as waterproof geotextile, is composed of a plastic film made of high-molecular materials such as polyethylene, and a non-woven fabric. The plastic film primarily serves the function of preventing seepage, and it exhibits outstanding tensile strength and elongation. When combined with the non-woven fabric, the composite further enhances its tensile strength and puncture resistance. It also increases the friction on the contact surface, providing greater stability. Additionally, both materials demonstrate strong resistance to corrosion, protecting against erosion and damage from various chemicals and bacteria.

Performance of composite Geomembrane:

1), The exceptionally high tensile strength and deformation resistance of waterproof geotextile contribute to the stability of soil or structures.

2), Waterproof geotextile possesses good water permeability and breathability, even under significant soil and water pressure. Installing waterproof geotextile in soil layers creates drainage channels, allowing the discharge of excess gas and liquid from the interior.

3), Waterproof geotextile is corrosion-resistant, acid-alkali-resistant, insect-resistant, and oxidation-resistant, resulting in a long service life.

Technical Parameters of Waterproof Geotextile:

The technical parameters of waterproof geotextile primarily include tensile strength, elongation at break, CBR (California Bearing Ratio) puncture strength, tear strength, etc. Different specifications of waterproof geotextile have varying technical parameters. For instance, for thicknesses of 0.9mm, 1.3mm, 1.7mm, 2.1mm, 2.4mm, 2.7mm, 3.0mm, 3.3mm, 3.6mm, 4.1mm, and 5.0mm, the tensile strengths are 2.5kN, 4.5kN, 6.5kN, 8.0kN, 9.5kN, 11.0kN, 12.5kN, 14.0kN, 16.0kN, 19.0kN, and 25.0kN, respectively. CBR puncture strengths are 0.3kN, 0.6kN, 0.9kN, 1.2kN, 1.5kN, 1.8kN, 2.1kN, 2.4kN, 2.7kN, 3.2kN, and 4.0kN, respectively. Tear strengths are 0.08kN, 0.12kN, 0.16kN, 0.20kN, 0.24kN, 0.28kN, 0.33kN, 0.38kN, 0.42kN, 0.46kN, and 0.60kN, respectively. The failure elongation is between 0.07 and 0.2.

Main Application:

1), hydraulic dam

In hydraulic dam engineering, composite geomembranes find extensive application as waterproof and impermeable layers. It serves as an effective water barrier in dam structures, composite geomembranes prevent water from penetrating the soil, ensuring the stability and safety of the dam. With high strength, durability, and exceptional chemical stability, these materials can withstand various environmental conditions, making them an indispensable component in hydraulic engineering projects.

2), transportation tunnel

Composite geomembranes play a crucial role as impermeable barriers in transportation tunnel engineering. It is employed to prevent water infiltration and enhance the waterproofing capabilities of tunnel structures. The use of composite geomembranes ensures the longevity and structural integrity of transportation tunnels by effectively managing water seepage, thereby contributing to the overall safety and durability of the tunnel infrastructure.

3), road and airport construction

In road and airport construction engineering projects, Composite geomembranes play multifaceted roles. With outstanding impermeability, they effectively resist water infiltration, safeguarding structures from water damage. Simultaneously, by enhancing soil stability, reducing lateral soil displacement, and increasing tensile strength, they contribute to overall structural stability. Also, composite geomembrane can serve as environmental isolation, preventing harmful substances from contaminating groundwater or surrounding environments. Their resistance to chemical corrosion and aging ensures long-term stability in diverse environmental conditions, extending the lifespan of the engineering projects.

4), drainage system

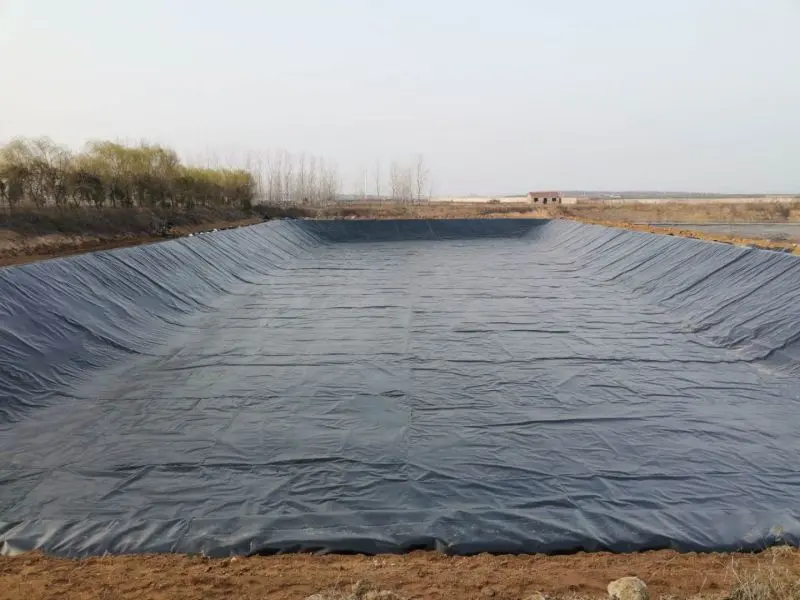

957532.webp)

In drainage system engineering, composite geomembranes are used as an impeccable choice for waterproofing and impermeable layers. Their exceptional impermeability effectively prevents water infiltration into the soil, thereby enhancing the efficiency of drainage systems. By employing composite geomembranes, a reliable waterproof barrier is established, preventing the adverse effects of water seepage on the engineering structures and surrounding soil. Furthermore, these geomembranes contribute to effective isolation of harmful substances within the drainage system, safeguarding against their entry into drainage channels and preserving the environment and water quality.

5, environmental protection

Composite geomembranes play an important role as an ideal choice for constructing environmental barriers. Their outstanding impermeability makes them effective in isolating hazardous substances, preventing contamination of soil and water. Composite geomembranes find application in various settings such as landfill sites and industrial waste areas, preventing the leakage of waste and ensuring the safety of environmental water quality. Their impermeability and chemical resistance make them valuable in environmental projects involving liquid storage and treatment, such as impermeable sewage ponds or wastewater treatment systems. The application of composite geomembranes in environmental engineering not only aids in pollution prevention but also enhances the stability of engineering structures, contributing significantly to sustainable development and ecological conservation.

The specifications of composite geomembrane we can supply

The specifications of composite geomembrane we can supply are as follows:

One fabric/one membrane | fabric:100—1000 g/m² | membrane thickness:0.1—1.5mm |

two fabric/one membrane | fabric:80—600 g/m² | membrane thickness:0.2—1.5mm |

one fabric/two membrane | fabric:100—1000 g/m² | membrane thickness:0.1—0.8mm |

mutiple fabric/mutiple membrane | fabric:100—1000 g/m² | membrane thickness:0.1—0.8mm |

You can choose the suitable specification according to your needs. If you have any questions about this product, please feel free to reach out us, looking forward to cooperate with you.

2, Geotextile fabric for waterproofing-geomembrane

what is geomembrane

The waterproofing function of geomembranes lies in providing a reliable impermeable and isolating layer, ensuring that liquids or gases cannot penetrate into the protected area.Geofabric membranes are typically made from polymer materials such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC).

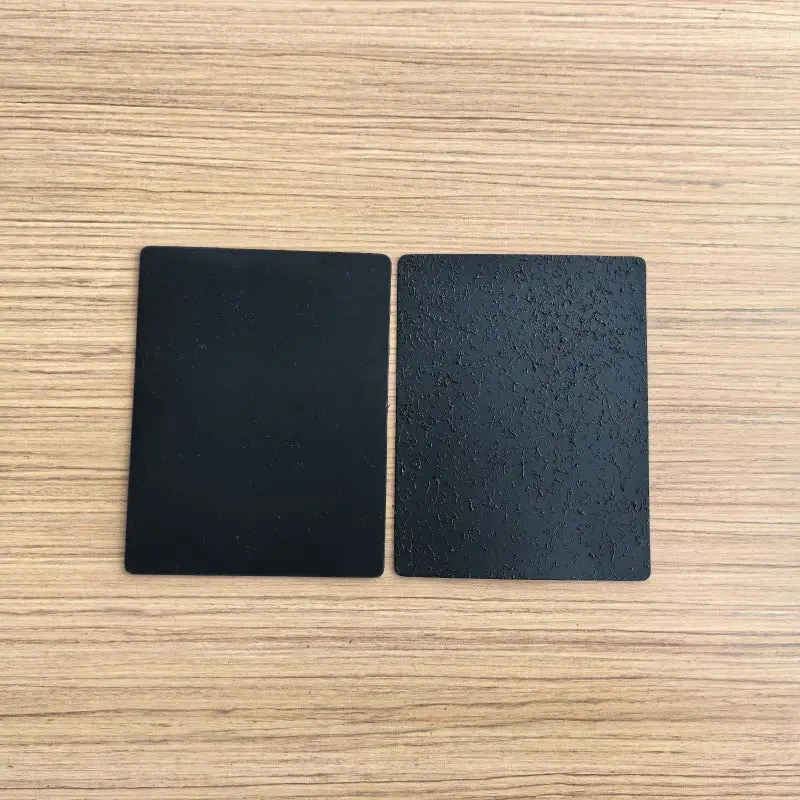

According to surface features, we can divided it into smooth-surface geomembranes and rough-surface geomembranes.

Smooth-surface geomembranes have a highly polished surface, lacking uneven structures, and therefore possess a lower friction coefficient. They are suitable for applications where a high level of surface smoothness is required, such as in water engineering projects and landfill lining for waste containment. In contrast, rough-surface geomembranes exhibit a certain degree of roughness with microscopic irregularities, resulting in a higher friction coefficient. These geomembranes are more suitable for scenarios requiring increased friction resistance or where surface smoothness requirements are relatively lower, such as in road base waterproofing and at the base of dams, especillay in slope area. The choice between smooth and rough-surface geomembranes depends on specific engineering requirements, ensuring optimal performance in various application areas.

Applications

As a material used for waterproofing and isolation, geofabric membranes are widely applied in civil engineering, environmental engineering, and hydraulic engineering. The waterproofing function of geomembrane is primarily manifested in the following aspects:

1), Groundwater Seepage Prevention

Geomembrane are usually used as an underground waterproofing layer to prevent the infiltration of water or pollutants through the soil into the groundwater. This is particularly crucial for groundwater protection in areas such as landfills, chemical plants, and oil fields.

2), Water Body Seepage Control:

Geomembranes are extensively used in water engineering projects such as reservoirs, rivers, and channels to prevent water from seeping into the soil or vice versa. This ensures the stability and effective management of water bodies.

3), Waste Solidification: In locations like landfill sites, geomembranes are employed to encapsulate and isolate waste, preventing harmful substances from waste materials from leaching into the soil and groundwater, thereby reducing the risk of environmental pollution.

4), Erosion Prevention: Geomembranes can be utilized to prevent soil erosion, especially in areas prone to erosion such as riverbanks and slopes. By installing geomembranes, it effectively protects the soil from erosion caused by water flow.

5), Wastewater Treatment: Geomembranes find applications in the field of wastewater treatment, preventing the leakage of treated sewage into the surrounding soil or groundwater.

3, Geotextile fabric for waterproofing-sodium bentonite geosynthetic clay liner

Sodium bentonite geosynthetic clay liner stands as an indispensable waterproofing material, offering a reliable and sustainable solution across various engineering domains, safeguarding structures, and preserving the integrity of the surrounding environment.

what is sodium bentonite geosynthetic clay liner

338566.webp)

As we can see from the picture, sodium bentonite geosynthetic clay liners are comprising a layer of sodium bentonite sandwiched between two geotextile layers, this innovative geosynthetic material is designed to provide exceptional waterproofing properties. Sodium bentonite, a natural clay with remarkable swelling capabilities when hydrated, forms a tight and impermeable barrier upon contact with water. This inherent quality makes GCLs highly effective in preventing water seepage and acting as a reliable liner in diverse settings.

Performance Features

Compared to compacted clay liners, it has many advantages compared with other waterproofing materials:

1), Small volume. GCLs are characterized by a compact design, resulting in a small volume. This feature makes them space-efficient and particularly suitable for projects where minimizing material bulk is important.

2), Light weight. The light weight of GCLs contributes to ease of handling and transportation. This characteristic enhances the efficiency of construction processes, especially in situations where the transportation and installation of heavy materials may be challenging.

3), Flexibility. GCLs are flexible and adaptable, allowing them to conform to the contours of the underlying soil or structures.

4), Excellent sealing. One of the key benefits of GCLs is their excellent sealing capability. The swelling properties of the sodium bentonite within the GCL create a robust impermeable barrier, effectively preventing water seepage and enhancing the liner's overall sealing performance.

5), Easy construction, and adaptability to uneven settlement.

GCLs are known for their ease of construction. They are often supplied in rolls, simplifying the installation process. Additionally, the adaptability of GCLs to uneven settlement or substrate conditions makes them versatile and well-suited for various construction environments.

Main applications

Because of its ecxellent waterproofing funtion and advantages, the sodium bentonite waterproofing blanket is widely used in various engineering applications, with three main areas of application:

1), Landfills:

Sodium bentonite waterproofing blankets are commonly employed as a barrier in the bottom layers of landfills. They form a waterproof barrier, effectively preventing liquid from waste materials from permeating into groundwater, thereby reducing the risk of groundwater contamination.

2), Water Engineering:

In water engineering projects, sodium bentonite waterproofing blankets find extensive use as liners in reservoirs, rivers, and channels. They efficiently prevent water from infiltrating into the soil or vice versa, ensuring the stability and sustainable management of water bodies.

3), Environmental Remediation:

Sodium bentonite waterproofing blankets play a crucial role in environmental remediation projects. They are often used to encapsulate and isolate contaminated soil, preventing the further spread of harmful substances and facilitating the restoration and remediation of polluted areas.

4, Factory display

Haoyang Invironmental is a Chinese manufacturing company established in 2008. Our factory Covers an area of over 230 acres, with more than 40,000 square meters of standardized industrial workshops, equipped with over 26 modern production lines for geosynthetic materials, the facility boasts a total annual production capacity of 93,500 tons. We possess the world's only 10-meter-wide, five-layer co-extrusion, online dual-sided rough spraying, nitrogen-assisted embossing blow molding geomembrane production line.

5, Our team

229958.webp)

Our company boasts a dedicated and professional team committed to excellence. Comprising experts from diverse fields, our team collaborates seamlessly to tackle challenges and deliver innovative solutions. From skilled technicians to experienced project managers, our professionals bring a wealth of expertise to every endeavor. Their collective commitment to quality, efficiency, and continuous improvement drives our company's success. Together, we form a dynamic force that not only meets but exceeds the expectations of our clients, ensuring the highest standards in every project we undertake.

FAQ

1. What makes a geotextile fabric the best choice for waterproofing?

The best geotextile fabric for waterproofing typically possesses a high tensile strength and excellent puncture resistance, ensuring durability and long-term effectiveness in preventing water seepage.

2. How does the permeability of geotextile fabric impact its suitability for waterproofing applications?

Geotextile fabrics with controlled permeability strike a balance by allowing water to pass through while retaining soil particles. This characteristic aids in effective drainage and prevents clogging, making them ideal for waterproofing projects.

3. What role does the fabric weight play in determining the effectiveness of a geotextile material for waterproofing?

The weight of geotextile fabric is indicative of its thickness and density. Heavier fabrics often provide better resistance to punctures and abrasion, enhancing their capability to serve as a reliable barrier against water infiltration.

4. Are there specific types of geotextile fabrics designed for particular waterproofing applications?

Yes, various geotextile fabrics are engineered for specific purposes. For instance, non-woven fabrics are commonly used in drainage applications, while woven geotextiles are preferred for stabilization. Choosing the right type ensures optimal performance in waterproofing projects.

5. How does UV resistance contribute to the longevity of geotextile fabric in waterproofing installations?

Geotextile fabrics with UV resistance are better equipped to withstand prolonged exposure to sunlight, ensuring a longer lifespan and sustained effectiveness in waterproofing applications, especially in outdoor or exposed environments.

411.webp)

897.webp)

942.webp)

237.webp)