Black and Green Two-Color Smooth Geomembrane by Haoyang

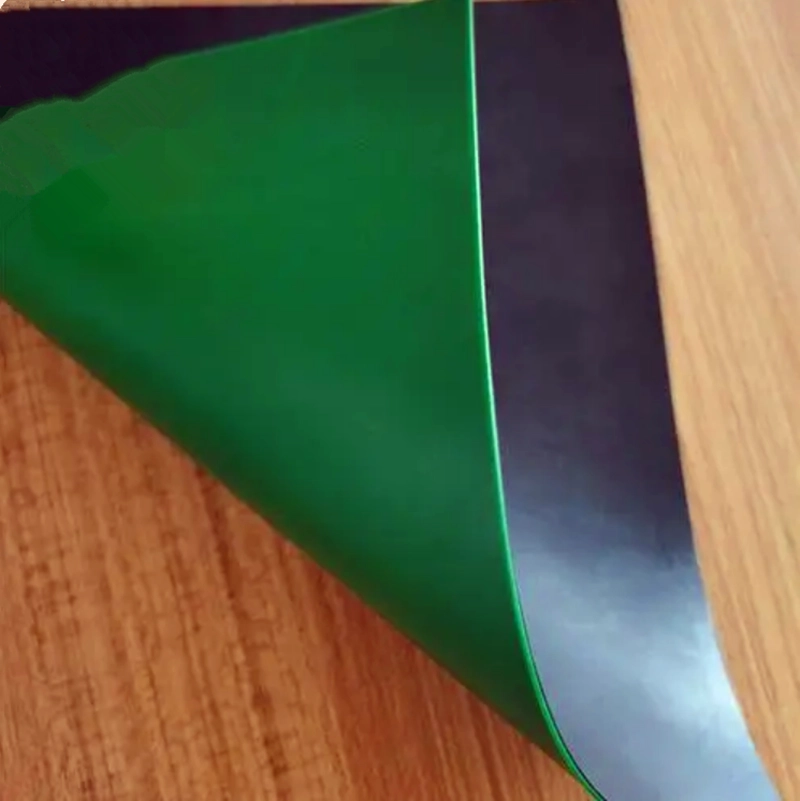

Introducing the Black and Green Two-Color Smooth Geomembrane from Haoyang Environmental Co., Ltd., a cutting-edge solution in geosynthetic materials. Established in June 2008, Haoyang is a high-tech comprehensive service provider specializing in environmental engineering consulting, design, construction, soil remediation, and comprehensive solid waste treatment and disposal. With a strong commitment to innovation and quality, we are dedicated to providing advanced and reliable environmental solutions.

Product Advantages

The Black and Green Two-Color Smooth Geomembrane is engineered to meet the highest standards of durability and efficiency for various environmental applications. Here are its key benefits:

Enhanced Visibility: The dual-color design ensures easy identification and installation, reducing the risk of incorrect placement.

Superior Durability: Made from high-quality materials, our geomembrane exhibits excellent resistance to punctures, tears, and environmental stressors, ensuring long-term reliability.

Chemical Resistance: It provides outstanding resistance to a wide range of chemicals, making it ideal for hazardous waste containment and other critical applications.

UV Protection: The geomembrane is treated with UV inhibitors to protect against degradation from sunlight, extending its lifespan.

Ease of Installation: Its smooth surface allows for quick and efficient installation, reducing labor costs and time on site.

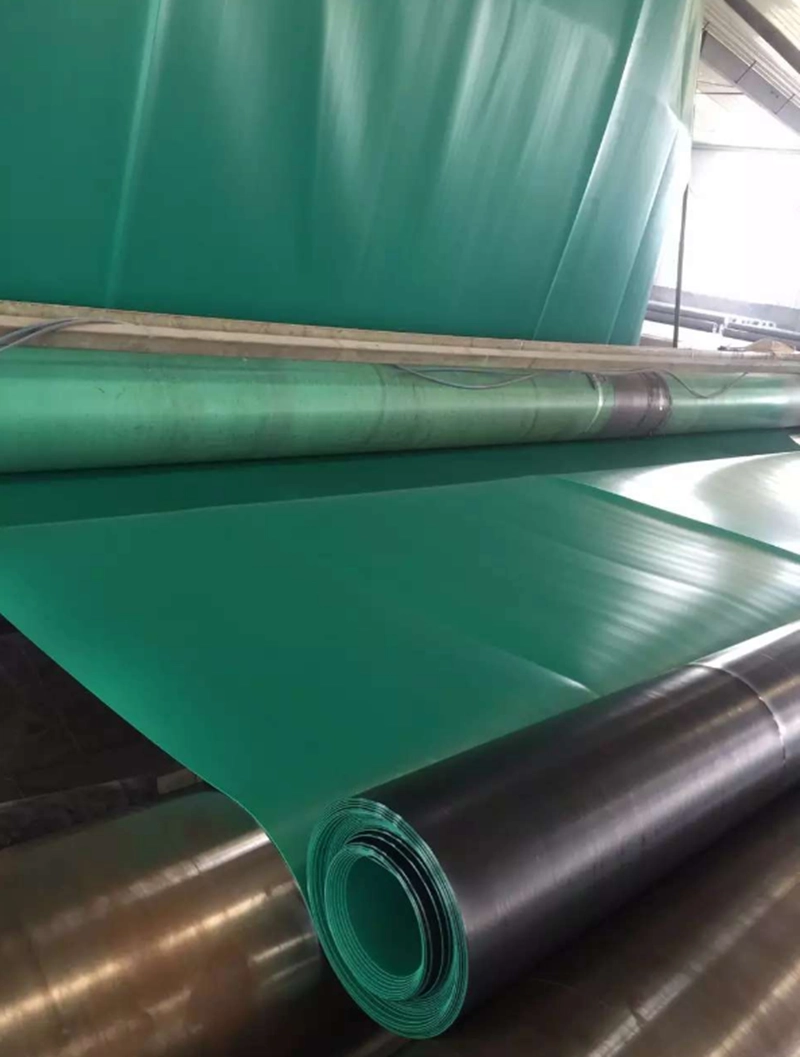

Factory Display

Welcome to the geomembrane production workshop of Haoyang Environment! It is a modern production site that combines advanced technology and innovative ideas. We have the largest radius of geomemofilm production equipment in the production process shows its unique advantages, perfectly meet the needs of customers, efficient extrusion machine with its precise temperature control and stable production speed, to ensure the uniformity and thickness accuracy of geomemofilm. At the same time, the advanced cooling system ensures the rapid solidification of the film, ensuring the quality and stable performance of the product.

This production workshop not only has superior equipment, more experienced team. Our staff are professionally trained and constantly explore innovative production methods to ensure that our geomembranes are always at the leading level in the industry.

Black And Green Two-Color Smooth Geomembran Technical Performance

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Technical Requirements

First, site foundation treatment:

(1) Foundation paving: clean the geomembrane laying surface, the requirements are basically smooth, solid soil, can not be uneven, cracks and so on. There can be no sharp objects, stones, wire, wood rods, etc., in the anti-seepage range of sod, roots to be cleared, for weeds to spray herbicide. The laying base should be solid and smooth, and the vertical depth of 25mm should not have roots, rubble, stones, concrete particles, steel bars, glass chips and other debris that may damage the impermeable film. Use a wheel compactor to remove car marks, footprints and ground bumps.

(2)When the HDPE impermeable film is laid on the backfill soil, the compaction degree of the backfill soil should not be less than 95%.

(3)The foundation should be dry treatment, site foundation should be free of seepage, silt, water, organic residue and may cause environmental pollution harmful substances.

(4)On the contact surface with the film, lay sand or clay layer with small particle size as a protective layer, and the thickness of the protective layer should not be less than 30cm.

Second, HDPE impermeable membrane construction process requirements.

(1)The construction process of HDPE impervious film shall be carried out in the following order: impervious film laying → matching welded joints → welding → field detection → repair → re-inspection → backfill

(2)The lap width of the seam between the film and the film is 100-150 mm.

(3)When laying HDPE impermeable film, the appropriate amount of expansion deformation should be reserved according to the local temperature change amplitude and foundation firmness and the performance requirements of HDPE impermeable film.

(4)After the HDPE impermeable film is laid, it should be minimized to walk on the film surface and carry tools.

(5)the HDPE impermeable film is laid, and before the protective layer is not covered, a 20-40Kg sandbag should be placed at the edge of the film every 2-5m to prevent the impermeable film from being blown up by the wind.

(6) HDPE impermeable film should be natural, with the support layer, should not fold, hanging.

(7)When the impervious membrane is constructed in sections, the upper layer should be covered in time after laying, and the time exposed in the air should not exceed 30 days.

Third, HDPE impermeable film welding requirements:

(1) HDPE waterproof film weld lap surface shall not have dirt, sand, water (including dew) and other impurities affecting the quality of welding, should be cleaned up during welding.

(2) At the beginning of welding every day (in the morning and after lunch break), it must be tested on the site first, and then formally welded after passing.

(3) The welding of HDPE impermeable film should be welded by a double-track hot melt welding machine, and the extrusion welding or hot air gun is only used in the repair, covering or hot melt welding machine can not reach.

(4) During construction, the working temperature and speed of the welding machine should be adjusted and controlled at any time according to the temperature and material properties.

(5) The HDPE film at the weld should be fused into a whole, and there should be no virtual welding, missing welding or excessive welding. The two layers of HDPE impermeable film must be bonded flat and soothing.

(6) HDPE geomembrane for T-type welding, pay attention to the edge to remove sharp corners, the use of geomembrane welding rod to strengthen the outer edge; The edges should also be reinforced with electrodes when performing circular welding.

Fourth, weld field detection method:

At present, there is no good method for on-site inspection of welds, in general, it is mostly visual inspection to see whether the two welds are smooth, clear, wrinkle-free, transparent, no slag, bubble leakage point, melting point or weld bubble edge.

(1) The two ends of the weld are welded with a welding gun, and then an air cylinder with a pressure gauge is used to clamp the gas needle, and the gas needle is inserted into a hole between the welds, and the distance of each section of the detection is about 1.5m to 3.0m, and the pressure is controlled at 0.5-2Mpa according to the requirements of the geosynthetic material test procedures, and the time is about 30s. When pumping, such as the gas inside the weld with the gas needle leakage, then as long as the needle part stuffed with plasticine, hit the air, press the finger in front of the gas needle, if observed for more than 30 seconds, the gas will not leak, then it is regarded as qualified connection.

(2) When testing with a microscope, put the microscope in a suspicious place, if there are leakage points, virtual points, use a welding torch or adhesive treatment.

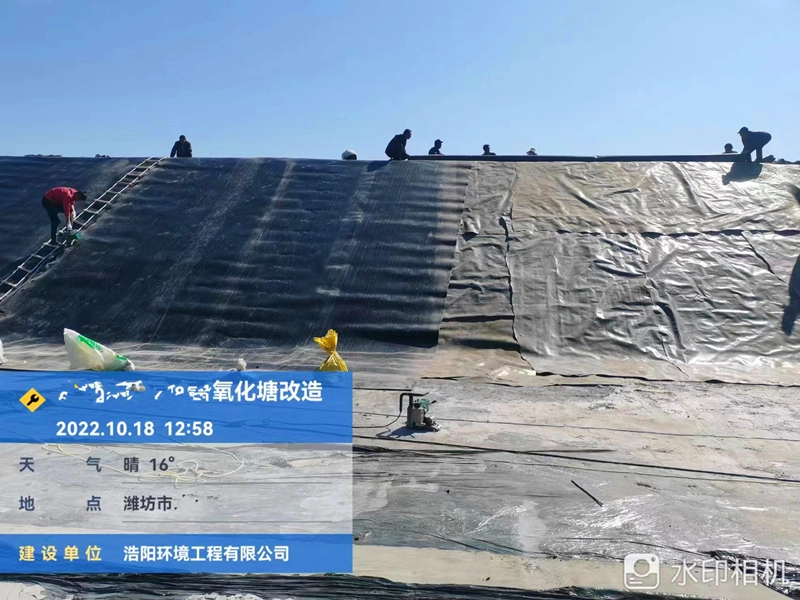

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

Product Application

Geomembrane has a wide range of application fields, mainly including but not limited to the following aspects:

(1)Waterproof works: Waterproof barriers for all kinds of engineering projects, such as basements, tunnels, reservoirs, river embankments and water conservancy projects, effectively prevent water penetration and leakage.

(2)Soil isolation: Used to isolate different soil layers or to stop contaminants from seeping into groundwater, such as in landfills, chemical plants, and wastewater treatment facilities.

(3)Soil stabilization and reinforcement: Used for the reinforcement and stabilization of soil, used in roads, railways, airports, retaining walls and land backfill and other engineering projects to enhance the stability and bearing capacity of the structure.

(4)Environmental protection: Used for environmental remediation and protection works to close or isolate contaminated land areas to prevent the spread of pollutants.

(5)Hydraulic engineering: In coastal protection, DAMS, water channels and artificial islands and other hydraulic engineering, to prevent water infiltration and erosion.

(6)Landscape design: Applied in landscape and landscape design as ground cover material, protect soil and vegetation, control water penetration.

(7)Mining and industrial applications: Used in mines, chemical plants and industrial facilities as an impermeable layer to prevent waste or harmful substances from leaking and protect the environment.

Company Advantages

Haoyang Environmental Co., Ltd. stands out as a leader in the industry due to our extensive experience and robust capabilities:

Certified Excellence: We have obtained ISO 9001, ISO 14001, and OHSAS 18001 certifications, along with the CQC environmental product certification, ensuring top-notch quality and safety standards.

Innovative R&D: Our professional technical R&D team is dedicated to the continuous development of cutting-edge environmental engineering materials and technologies. With three invention patents and 32 utility model patents, we are at the forefront of innovation.

Recognized Expertise: Haoyang has been recognized as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory" by the National Laboratory, showcasing our commitment to excellence and technological advancement.

Proven Success: With two provincial-level scientific and technological achievement certifications, our solutions are proven and trusted by industry leaders.

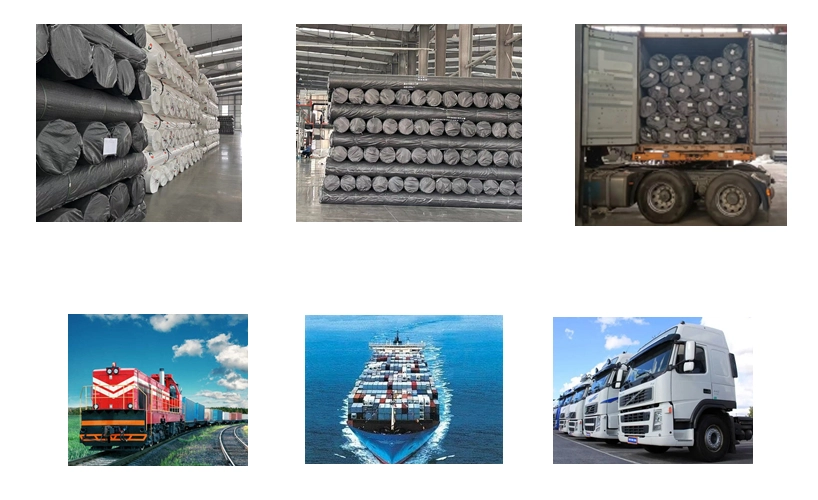

Mode of Transport

We ensure timely delivery of goods.

Contact Us

For more information about our Black and Green Two-Color Smooth Geomembrane or to discuss your project needs, please contact us. Partner with Haoyang Environmental Co., Ltd. for reliable, innovative, and high-quality environmental solutions. Together, we can build a sustainable future.

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1mm Single-texture HDPE geomembrane.pdf

1mm Single-texture HDPE geomembrane.pdf

![]() 2mm Single-texture HDPE geomembrane.pdf

2mm Single-texture HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

503.webp)

759.webp)

574.webp)

585.webp)

523.webp)