Enhancing Reservoir Dam Sustainability with Haoyang's Geomembrane Solutions

As the global demand for clean water and sustainable infrastructure continues to rise, reservoir dams play a pivotal role in water resource management. However, ensuring the longevity and safety of these vital structures presents ongoing challenges. Here at Haoyang Environmental Co., Ltd., we offer cutting-edge geomembrane solutions that revolutionize reservoir dam construction and maintenance, elevating standards of durability, environmental protection, and cost-effectiveness.

Problem Statement

Traditional reservoir dam construction often faces issues such as seepage, erosion, and environmental degradation, leading to compromised structural integrity and increased maintenance costs. Conventional solutions struggle to address these challenges adequately, often falling short in long-term sustainability and effectiveness.

Solution Offered

Enter Haoyang's advanced geomembrane technology. Engineered with precision and innovation, our geomembranes serve as impermeable barriers, effectively sealing reservoir dams and mitigating seepage concerns. Crafted from high-quality geosynthetic materials, our solutions offer unparalleled strength, flexibility, and resistance to environmental factors, ensuring reliable performance even in the most demanding conditions.

Benefits

Enhanced Durability: Haoyang's geomembranes are designed to withstand harsh environmental conditions, including UV exposure, chemical erosion, and temperature fluctuations, ensuring long-lasting performance and minimal maintenance requirements.

Superior Seepage Control: By forming a robust barrier against water infiltration, our geomembranes prevent seepage and leakage, safeguarding the structural integrity of reservoir dams and preserving water resources.

Environmental Protection: With a commitment to sustainability, our geomembrane solutions promote eco-friendly reservoir dam construction practices, minimizing soil contamination, habitat disruption, and water pollution.

Cost-Effectiveness: By reducing the need for frequent repairs and maintenance, Haoyang's geomembranes offer significant cost savings over the lifespan of reservoir dams, making them a smart investment for governments, utilities, and private developers alike.

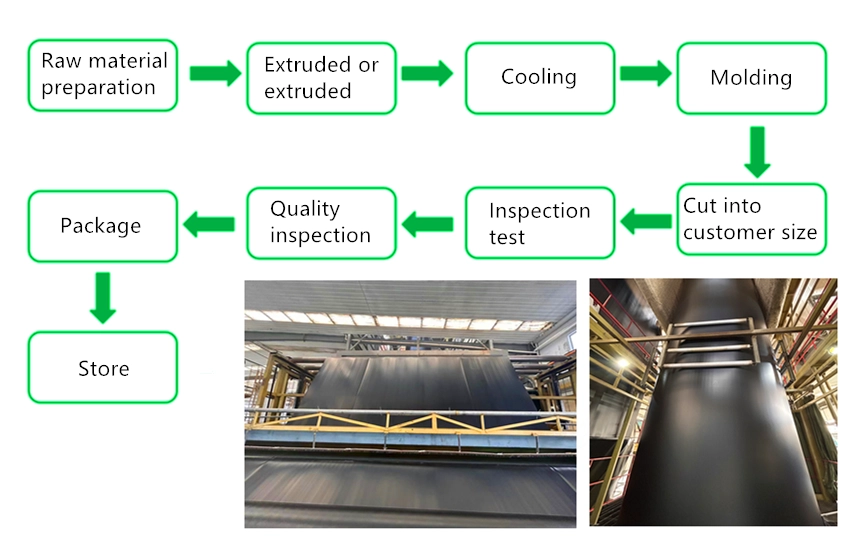

How is Our Geomembrane Produced?

Geomembrane is formed through the extrusion production process, the specific steps are as follows:

↘ First of all, raw material preparation: according to the required characteristics of the geomembrane, select high-quality polymer resins, such as polyethylene (HDPE), etc. Different masterbatches can be added to harmonize the color of the geomembrane.

↘ Secondly, extrusion: the selected polymer resin is heated and melted in the extruder. The molten polymer is then pushed into the mold to form a continuous sheet or film.

↘ The third is calendering or rolling: the extruded sheet is pressed through a roller to smooth the material, ensuring uniform thickness and surface finish.

↘ The fourth is cooling and solidification: the flat sheet is cooled by cooling rollers or water baths. This rapid cooling process solidifies the polymer into a stable geodiaphragm.

↘ The fifth is testing and quality control: the geomembrane is inspected for quality and tested for parameters such as thickness, tensile strength, tear resistance and flexibility to ensure that it meets industry standards and specifications.

↘ The sixth is finishing: geomembrane can be processed through additional surface texturing or surface treatment processes to improve specific performance characteristics if required for certain applications. The geomembrane of Haoyang environment can make single or double rough surface.

↘ Finally, cutting and packaging: once the quality check is passed, the geomembrane is cut to the desired size, rolled into large scrolls or folded into specific sizes, packaged and shipped to the end user or stored. Haoyang environment has a complete testing center, each batch of products must go through strict testing before shipping.

The production of geomembranes involves precise control of temperature, pressure and quality checks throughout the manufacturing process to ensure consistency and compliance with standards.

Geomembrane Advantages and Applications

(1) The membrane has excellent waterproof and impermeable function, which can effectively isolate water, chemicals or pollutants from penetrating into the soil or structure. It can be used as a waterproof barrier for basements, tunnels, reservoirs, river embankments, water conservancy projects and other projects to effectively prevent water seepage and leakage.

(2) Geomembranes have soil isolation: used to isolate different soil layers or prevent pollutants from seeping into groundwater, such as in landfills, chemical plants and wastewater treatment facilities.

(3) It also has good chemical resistance, can resist acid, alkali, chemical erosion, suitable for a variety of engineering environments, can be used for soil reinforcement and stability, for roads, railways, airports, retaining walls and land backfill and other engineering projects to improve the stability of the structure and carrying capacity.

(4) With tensile tear strength: with a certain mechanical strength and toughness, can withstand a certain amount of stretching, tearing and puncture pressure, enhance the stability of the soil.

(5) Aging resistance: good aging resistance, can resist ultraviolet light, high temperature, low temperature and oxidation, maintain long-term stability.

Cooperate with Haoyang

Haoyang's geomembrane solutions have been successfully implemented in reservoir dam projects worldwide, delivering measurable results in terms of seepage control, structural stability, and environmental conservation. Our track record of excellence speaks volumes about the efficacy and reliability of our products in real-world applications.

In an era where sustainable infrastructure solutions are paramount, Haoyang Environmental Co., Ltd. stands at the forefront of innovation with our state-of-the-art geomembrane technology. By partnering with us, stakeholders in reservoir dam projects can elevate performance standards, enhance environmental stewardship, and secure a brighter, water-secure future for generations to come. Choose Haoyang for geomembrane solutions that redefine excellence in reservoir dam construction and maintenance.

Factory Display

Welcome to the geomembrane production workshop of Haoyang Environment! It is a modern production site that combines advanced technology and innovative ideas. We have the largest radius of geomemofilm production equipment in the production process shows its unique advantages, perfectly meet the needs of customers, efficient extrusion machine with its precise temperature control and stable production speed, to ensure the uniformity and thickness accuracy of geomemofilm. At the same time, the advanced cooling system ensures the rapid solidification of the film, ensuring the quality and stable performance of the product.

This production workshop not only has superior equipment, more experienced team. Our staff are professionally trained and constantly explore innovative production methods to ensure that our geomembranes are always at the leading level in the industry.

Common HDPE Geomembrane (GH-1 type) Technical Performance

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

HDPE Geomembrane Welding Requirements

(1) HDPE waterproof film weld lap surface shall not have dirt, sand, water (including dew) and other impurities affecting the quality of welding, welding should be cleaned up.

(2) At the beginning of welding every day (in the morning and after lunch break), it must be tested on the site first, and then formally welded after passing.

(3) The welding of HDPE impervious film should be welded by double-track hot melt welding machine, and only use extrusion welding or hot air gun when repairing, which can not be reached by covering or hot melt welding machine.

(4) During the construction process, the working temperature and speed of the welding machine should be adjusted and controlled at any time according to the temperature and material properties.

(5) The HDPE film at the weld should be fused into a whole, and should not be virtual welding, missed welding or over-welding. Two layers of HDPE impermeable film must be bonded flat and soothing.

(6) When the HDPE geomembrane is T-welded, pay attention to the removal of sharp edges and use geomembrane welding rods to strengthen the outer edges; In circular welding, the edges should also be reinforced with electrodes.

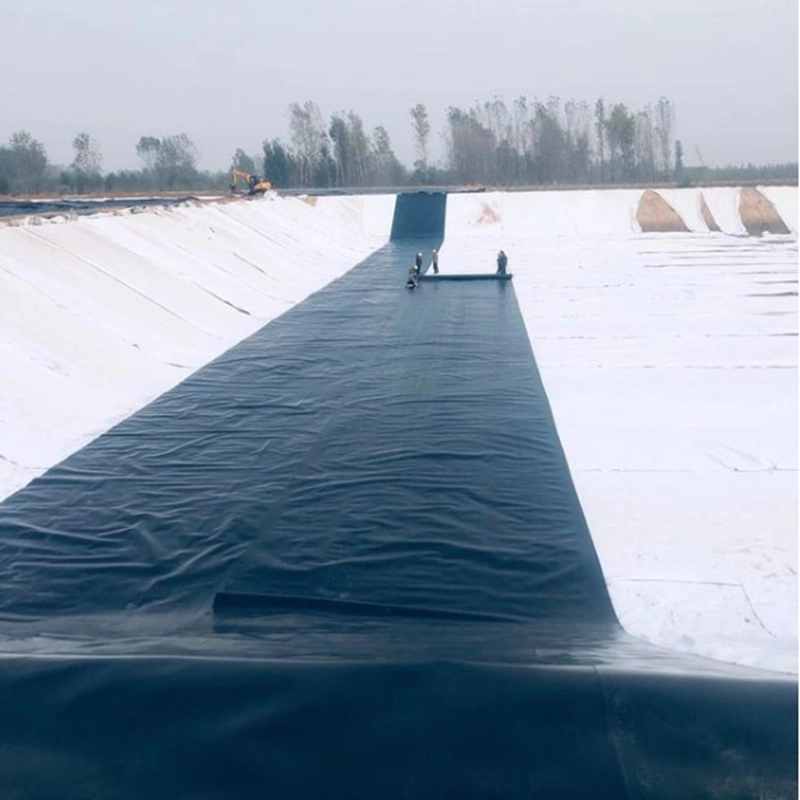

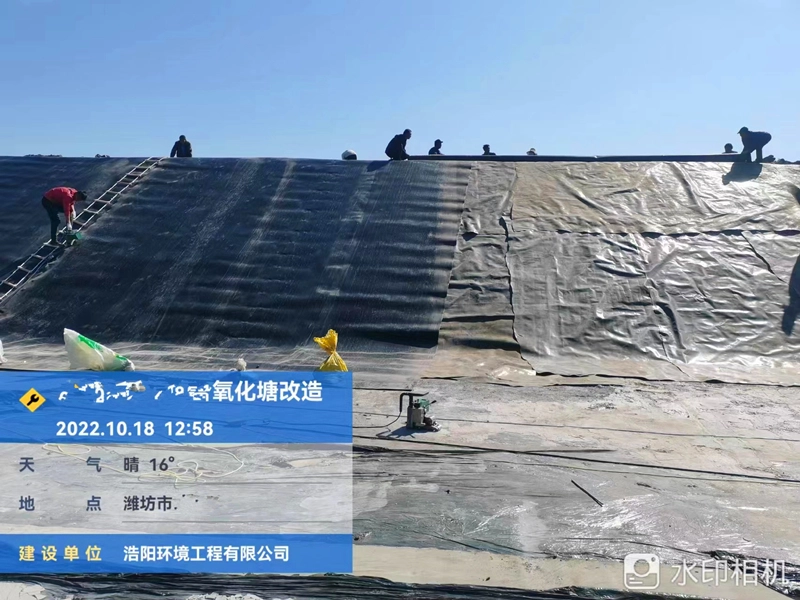

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

FAQ

Q1: What is the main material of this geomembrane?

A1: Our geomembranes are usually made of plastic materials such as polyethylene (HDPE).

Q2: What are its main uses?

A2: Mainly used in soil separation, drainage, waterproofing, protection and other projects to prevent soil erosion and protect infrastructure.

Q3: What is the lead time?

A3: Usually 5-10 working days after receiving the deposit.

Q4: Can you produce according to the customer's requirements?

A4: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q5: How do you guarantee the quality testing of your products?

A5: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q6: What about product price and quality assurance?

A: We offer competitive prices and guarantee that our products meet quality standards to ensure that our customers receive high quality products.

Q7: Is this geomembrane environmentally friendly?

A7: Geomembranes are often manufactured from recycled materials, meet environmental standards, and remain stable after use

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1mm Single-texture HDPE geomembrane.pdf

1mm Single-texture HDPE geomembrane.pdf

![]() 2mm Single-texture HDPE geomembrane.pdf

2mm Single-texture HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

503.webp)

759.webp)

574.webp)

585.webp)

523.webp)