Ø Definition

Geotextile is a kind of geosynthetic material used in civil engineering. It is a fabric made of synthetic fibers such as polyester (PET) and polypropylene (PP) processed by needling, hot bonding or weaving. The development of geotextiles originated in the middle of the 20th century, with the continuous progress of civil engineering technology and the improvement of material performance requirements, it has gradually become an indispensable engineering material.

346941.webp)

Ø Characteristics of geotextiles

1. Chemical resistance

Geotextile has good acid and alkaline resistance, and can maintain stable chemical properties within a certain pH range (such as pH 2-13).

2. Aging resistance

Aging resistance is one of its important characteristics. By adding anti-aging agents and other measures, high-quality geotextiles can be used for a long time in the outdoor environment and the performance decline is small, extending its effective use life in the project.

3. Convenient construction

geotextile material is light and soft, easy to transport, lay and construction.

Good antimicrobial resistance: it is not sensitive to microorganisms and insects, and will not be damaged.

4. Water permeability

Good water permeability is one of the key characteristics of geotextiles. It allows water to pass through smoothly, which is very important for drainage systems.

5. filterability

The filtration property of geotextile means that it can prevent soil particles from being carried away by water flow while allowing water to pass through.

Ø Classification of geotextiles

1. Classified by manufacturing method

1) Non-woven geotextile:

It is made by needling, hot bonding and other non-woven processes. For example, needled non-woven geotextile is the short fiber or filament fiber carded into a net, the use of barbed needles repeatedly puncture, so that the fibers intertwined with each other to strengthen. This geotextile has a high porosity and can filter and drain well.

2) Woven geotextile:

Woven geotextiles are made by weaving yarn through warp and weft. It has high tensile strength, compact structure and low elongation. Just like ordinary fabric, it has a clear longitude and latitude structure. It can be used as a reinforced material to prevent soil from large deformation and landslide due to external force.

3) Composite geotextile:

Composite geotextile is the combination of non-woven geotextile and woven geotextile or other materials through the composite process. It has both the filtration performance of non-woven geotextiles and the strength characteristics of woven geotextiles. This kind of geotextile is used in complex environmental projects such as water conservancy projects and landfill sites with high requirements.

985668362040893007.webp)

2. Classification by use

Drainage and filtration type geotextile:

Mainly used for drainage and filtration. It allows liquids, such as water, to pass through smoothly while preventing the loss of soil particles. It is used in the drainage system of water conservancy project, the side ditch drainage of highway and so on.

1) Isolated geotextile:

Used to isolate materials of different properties. For example, in the construction of railway tracks, it is placed between the ballast and the foundation soil to prevent the ballast from being embedded in the foundation soil, and to avoid the fine particles in the foundation soil from entering the ballast layer.

2) Wrapped geotextile:

The main function is wrapping. It can be wrapped in soil, sand or other loose materials to protect and fix.

3) Reinforced geotextile:

Can provide additional tensile strength to the soil. In the soft soil foundation treatment or slope reinforcement project, the geotextile is buried in the soil, when the soil is subjected to external force, the geotextile can withstand part of the tension, reduce the possibility of soil deformation and damage, and enhance the stability of the slope.

668985.webp)

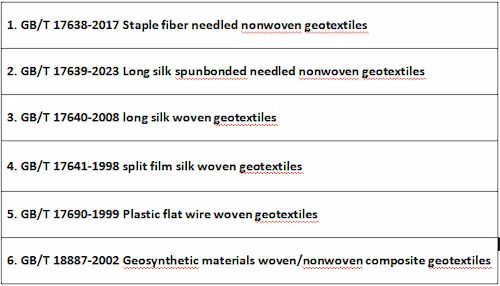

Ø Geotextile commonly used product standards

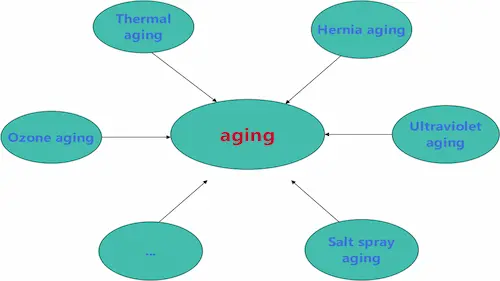

Ø Aging problem of geotextile

(As shown below)

1. The details are as follows:

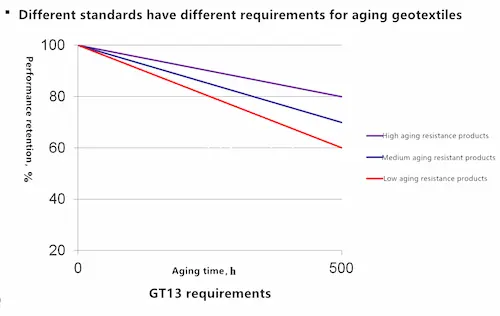

1) Different standards have different requirements for aging geotextiles

-GT 13 standard: geotextile after 500 hours of aging, the performance retention rate is 60%-80%.

-China's landfill industry standard: geotextile after 500 hours of aging, the performance retention rate is 70%.

2) Different standards require different aging test methods for geotextiles

Xenon lamp aging:

Different standards have different temperature and humidity requirements for -xenon lamp aging.

-Ultraviolet aging:

Different standards for the amount of radiation and test temperature requirements will be different.

3) The production enterprise shall confirm the standard requirements and corresponding test methods before production

Ø The application of geotextiles

1. Water conservancy projects

1) Dam protection

Geotextile can be used for slope protection of levees to prevent slope damage caused by wave erosion and rain erosion. It acts as an isolation and protection, separating the slope soil from external water flow and weathering factors, and protecting the structural integrity of the levee.

2) Channel seepage prevention

In irrigation channels, geotextiles can be laid on the bottom and side walls of channels to prevent seepage. At the same time, geotextile can also be used as a liner for the channel to protect the concrete or soil structure of the channel to prevent wear and damage caused by long-term erosion by water flow.

2. Highway and Railway engineering

1)Pavement base

Geotextile can be used as isolation layer in the base construction of road and railway pavement. It can separate the soil of the base from the rubble or asphalt layer above. Geotextile can also play a reinforcing role, enhance the bearing capacity of the road base, so that the road can withstand greater traffic load, extend the service life of the road.

2)Subgrade drainage

Laying geotextiles in the roadbed can form an effective drainage channel, discharge the groundwater in the roadbed, and reduce the water content of the roadbed.

3. Construction projects

1) Foundation moisture resistance

In the foundation part of the building, geotextile can be used as a moisture barrier. It can prevent underground moisture from penetrating into the foundation and walls of the building and protect the structural materials of the building.

2) Basement waterproofing

In the basement waterproof project, geotextiles are often used in conjunction with other waterproof materials. Geotextiles can be used as an auxiliary waterproof layer to enhance the waterproof effect, while protecting the main waterproof material from damage during construction.

4. Environmental protection projects

1) The landfill

Geotextiles have many applications in landfills. It can be used as a liner material to lay on the bottom and side of landfill pits. Geotextiles can also be used to cover landfills, reducing rainwater infiltration into the waste layer.

2) Sewage treatment

In sewage treatment facilities, geotextiles can be used as filter materials for the preliminary filtration of sewage, to remove suspended solids and some impurities in sewage, and to improve the treatment efficiency of sewage.

Ø Summarize

In the future development, geotextiles will have a far-reaching impact. With the continuous advancement of infrastructure construction, the amount of geotextiles will continue to increase in roads, Bridges, water conservancy and other projects. It helps to improve the quality of the project and reduce the later maintenance cost. In the field of environmental protection, geotextiles can be used in landfills to prevent landfill leachate from polluting soil and groundwater. In addition, with the continuous development of materials science, the performance of geotextiles will continue to optimize, and there will be new breakthroughs in smart materials and sustainable development, such as the development of geotextiles with self-healing functions, to promote the further development of related industries.

897.webp)

942.webp)

237.webp)