Composite Geomembrane

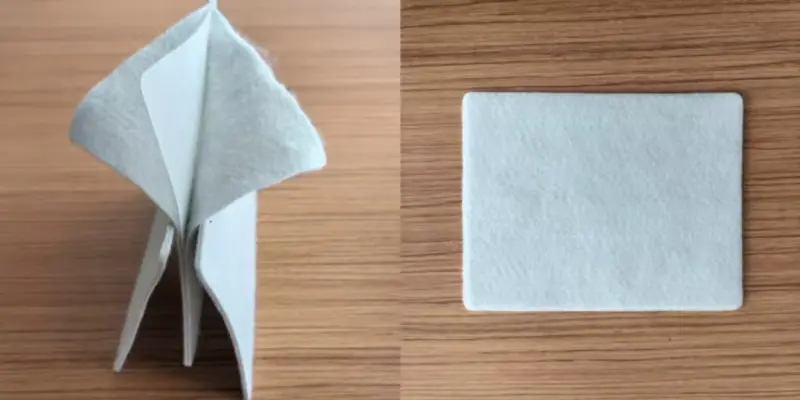

Composite Geomembrane 150g/㎡-0.3mm-150g/㎡ is a kind of geosynthetic membrane composed of three layers of different materials. The middle layer is geomembrane, and the two sides are filament nonwoven geofabrics, these layers are bonded together through a composite process to leverage their respective strengths, providing enhanced functionality and performance to meet the specific requirements of engineering applications. You are welcome to contact us at any time.

Composite geomembranes are advanced geosynthetic materials that combine the properties of geomembranes and geotextiles, providing an effective solution for waterproofing and reinforcement in various civil engineering projects. These materials are widely used in applications such as landfill liners, reservoirs, tunnels, and road construction, where both waterproofing and mechanical strength are crucial. In this article, we will explore the key features, specifications, applications, and benefits of composite geomembranes in civil engineering, with a particular focus on their waterproofing function.

Composite Geomembrane Specifications

We can supply different kinds of specifications according to your requirements.

middle: geomembrane thickness: 0.3mm

two sides: filament nonwoven geofabrics 150g/㎡

| Items | Technical standard | Results | Evaluation |

| Mass per unit area of composite membrane(g/㎡) | 600 | 607 | qualified |

| Thickness of geomembrane(mm) | ≥0.30 | 0.31 | qualified |

| Mass per unit area of filament nonwoven geofabric(g/㎡) | 150x2 | 152x2 | qualified |

| peel strength(N/cm) | ≥6 | 7.6 | qualified |

| CBR top breaking force(kN) | ≥3.0 | 3.2 | qualified |

| hydrostatic pressure resistance(MPa) | ≥0.6 | No leakage at 0.6MPa | qualified |

| longitudinal fracture strength(kN/m) | ≥17.0 | 20.8 | qualified |

| elongation at nominal tensile strength(%) | 30-100 | 65 | qualified |

| transverse fracture strength(kN/m) | ≥17.0 | 19.1 | qualified |

| transverse elongation at nominal tensile strength(%) | 30-100 | 68 | qualified |

| longitudinal trapezoidal tear(kN | ≥0.42 | 0.5 | qualified |

| transverse trapezoidal tear(kN) | ≥0.42 | 0.49 | qualified |

| vertical permeability coefficient(cm/s) | / | 4.96x10-12 | qualified |

Specifications of Composite Geomembrane

The specifications of composite geomembranes can vary depending on the requirements of the project. Below is a general specifications table for typical composite geomembranes used in civil engineering:

| Specification | Details |

|---|---|

| Geomembrane Material | HDPE, LLDPE, PVC |

| Geotextile Material | Non-woven Polypropylene or Polyester |

| Thickness of Geomembrane | 0.5 mm to 2.0 mm |

| Geotextile Weight | 200 g/m² to 600 g/m² |

| Tensile Strength | ≥ 30 kN/m |

| Elongation at Break | ≥ 700% |

| Puncture Resistance | ≥ 1000 N |

| Water Permeability | ≤ 1.0 × 10⁻¹³ g.cm/cm².s.Pa |

| Roll Width | 4 m to 6 m |

| Roll Length | 50 m to 200 m (customizable) |

| UV Resistance | Excellent (with UV inhibitors) |

| Chemical Resistance | Resistant to acids, alkalis, and solvents |

| Temperature Range | -30°C to 80°C |

| Standard Compliance | ASTM D5199, ASTM D5397, ISO 9001 |

Features of Compostie Geomembrane

1. Multilayer Construction: Composite geomembranes typically consist of two or more layers of different geosynthetic materials, such as a geomembrane layer and a reinforcing geotextile layer.

2. Enhanced Strength: The inclusion of a reinforcing component, such as geotextile, provides additional strength to the geomembrane, improving tensile strength, tear resistance, and puncture resistance.

3. Customizable Thickness: Composite geomembranes are available in various thicknesses, allowing for customization based on the specific requirements of a project.

4. Permeability Control: Depending on the application, composite geomembranes can be engineered to control the permeability of gases and liquids, making them suitable for containment purposes in environmental engineering projects.

5. Temperature Stability: They are designed to withstand a range of temperatures, ensuring performance and stability under varying environmental conditions.

6. Durable and Long-lasting: Composite geomembranes are engineered to be durable and have a long service life, making them suitable for applications where long-term performance is essential.

Applications of Compostie Geomembrane

1. Landfill Liners:

Composite geomembranes are often used as liners in landfill sites to contain and prevent the leachate (liquid that drains from the landfill) from contaminating the surrounding soil and groundwater.

2. Pond and Reservoir Liners:

They are employed in the construction of ponds, reservoirs, and other water containment structures to prevent seepage and leakage, maintaining water quality and preventing environmental damage.

3. Mining and Heap Leach Pads:

In mining operations, composite geomembranes are used in heap leach pads and tailings storage facilities to control the flow of liquids, prevent soil erosion, and protect the environment from potential contaminants.

4. Secondary Containment:

Composite geomembranes are utilized in secondary containment systems for industrial facilities to prevent the leakage of hazardous substances, such as chemicals or petroleum products, into the environment.

5. Water and Wastewater Treatment:

They play a role in water and wastewater treatment facilities as liners for tanks, lagoons, and other containment structures, ensuring the integrity of the containment systems.

6. Tunnel Waterproofing:

Composite geomembranes are applied in tunnel construction for waterproofing purposes, preventing water ingress into tunnels and underground structures.

7. Oil and Gas Industry:

Used in the oil and gas industry for containment of drilling fluids, wastewater, and other potentially harmful substances, helping to mitigate environmental impacts.

8. Agricultural Applications:

Composite geomembranes are employed in agricultural projects, such as lining irrigation ponds or preventing contamination of agricultural runoff.

About Haoyang

Introducing Haoyang Environmental Co., Ltd., a pioneering force in the realm of environmental solutions and geosynthetic materials. Since its establishment in June 2008, Haoyang has continuously surged ahead as a high-tech comprehensive service provider specializing in a wide array of environmental services, ranging from research and development to manufacturing, consulting, and comprehensive waste treatment.

At the forefront of its offerings stands the Composite Geomembrane for Civil Engineering, a testament to Haoyang's commitment to innovation and excellence. This specialized product epitomizes the intersection of cutting-edge technology and environmental stewardship, serving as a cornerstone in the realm of civil engineering projects.

With a robust suite of certifications including ISO 9001, ISO 14001, OHSAS 18001, and CQC environmental product certification, Haoyang exemplifies industry-leading quality and adherence to global standards. Furthermore, its accolades as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory" underscore its position as a frontrunner in environmental innovation.

Powered by a dedicated team of professionals, Haoyang boasts a formidable research and development arm, with a focus on environmental engineering design, material development, and pollution control technologies. The company's impressive patent portfolio, comprising three invention patents and 32 utility model patents, alongside provincial-level scientific and technological achievements, attests to its unwavering commitment to pushing the boundaries of environmental sustainability.

In essence, Haoyang Environmental Co., Ltd. stands as a beacon of excellence in the realm of environmental solutions, with its Composite Geomembrane for Civil Engineering paving the way for a greener, more sustainable future in civil engineering endeavors.

Successful Case

The south-to- North Water Diversion project is one of China's most ambitious projects with a total investments of 500 billion yuan.

As a professional manufaturer and supplier of geosythetic materials, our company has participated in the construction of multiple projects, proving Composite Geomembrane 150g/㎡ as required, composite geomembranes play a crucial role in various aspects of this project, including preventing water seepage, reinforcing structures, and ensuring the overall integrity and efficiency of the water diversion system.

our supply is timely, the quality is reliable, and the construction is smooth, all projects meet the standards. The construction rate was 100% and the construction tasks were completed well.

Factors Influce the Price of Geofabrics

The price of geotextiles can be influenced by various factors, and it's important to consider these factors when evaluating costs for a specific project. Here are some key factors that can influence the price of geotextiles:

1. Material Type:

Geotextiles can be made from different materials, such as polypropylene, polyester, or polyethylene. The type of material can impact the cost, with some materials being more expensive than others.

2. Weight and Thickness:

Geotextiles come in various weights and thicknesses. Heavier and thicker geotextiles often cost more due to the increased amount of material used in their production.

3. Construction Type:

There are different types of geotextiles, including woven, non-woven, and knitted. The manufacturing process and type of construction can affect the price. Non-woven geotextiles, for example, are often less expensive than woven ones.

4. Strength and Durability:

Geotextiles with higher strength and durability characteristics may cost more. These properties are crucial for applications where the geotextile needs to provide long-term stability and support.

5. Market Conditions:

General market conditions, including fluctuations in raw material prices, supply and demand dynamics, and economic factors, can impact the price of geotextiles.

6. Shipping and Logistics:

The cost of transporting geotextiles to the project site can contribute to the overall expenses.

Composite geomembranes are a vital component in civil engineering projects that require robust waterproofing and mechanical reinforcement. With their unique combination of geomembrane and geotextile layers, they provide a versatile and effective solution for a wide range of applications, from landfill liners to tunnel waterproofing. By adhering to international standards and offering customizable specifications, composite geomembranes meet the diverse needs of modern infrastructure projects. For detailed pricing, customization options, and further assistance, it is recommended to consult with reputable suppliers or manufacturers.

503.webp)

759.webp)

992.webp)

855.webp)