Composite Geomembrane Materials by Haoyang

Shandong Haoyang Environmental Co., Ltd., established in 2008, is a high-tech service provider specializing in geosynthetic material R&D, manufacturing, and environmental engineering solutions. With a focus on innovation and sustainability, Haoyang introduces its premium Composite Geomembrane Materials, designed for superior performance in a wide range of engineering and environmental applications. Our cutting-edge production technology ensures that every product meets the highest industry standards, offering exceptional quality and reliability.

Product Advantages

High Durability: Engineered to withstand extreme conditions, composite geomembranes offer excellent resistance to tearing, punctures, and environmental stress.

Superior Barrier Performance: With adjustable permeability levels, these geomembranes provide unmatched containment capabilities for water, gas, and hazardous materials.

Flexible Customization: Thickness, tear resistance, and other parameters can be tailored to meet specific project requirements, ensuring optimal performance.

Eco-Friendly Production: Produced using advanced, energy-efficient equipment with low noise and energy consumption, aligning with global sustainability goals.

Cost-Effective Solution: Long-lasting materials reduce maintenance and replacement costs, delivering superior value for money.

Applications

Composite geomembranes are versatile and can be used in a variety of industries, including:

Environmental Engineering: Landfills, hazardous waste containment, and soil remediation projects.

Water Management: Reservoirs, canals, and irrigation systems.

Construction Projects: Tunnels, foundations, and retaining walls for waterproofing and erosion control.

Industrial Applications: Tailings dams, chemical storage facilities, and oil containment systems.

Haoyang Environmental Co., Ltd. - Creating a durable and reliable composite geomembrane solution

At Haoyang Environmental Co., Ltd., we focus on providing you with high-quality, reliable composite geomembranes that are widely used in various engineering fields to help you solve problems such as soil stability, waterproofing and seepage prevention, filtration, and drainage. Our products combine advanced technology and strict quality control to ensure durability under various environmental conditions.

I.high-quality materials, excellent performance

Our composite geomembranes are made of high-quality polymer materials, featuring high strength, high durability, high waterproofness, and high impermeability. These materials are carefully selected and tested to ensure excellent performance under various soil conditions and hydrological conditions. We are aware of the importance of material quality for engineering, so we insist on using high-quality materials that meet international standards. Composite geomembrane is an engineering material composed of geomembrane and other geotechnical materials, which has various advantages and wide application fields. Here are some introductions about composite geomembrane:

Definition and composition: Composite geomembranes are engineering materials composed of a geosynthetic material (such as geotextile or geogrid) combined with a geomembrane. They are classified into one-fabric one-film and two-fabric one-film. They utilize the advantages of different materials to improve soil stability, waterproofness, impermeability, and durability.

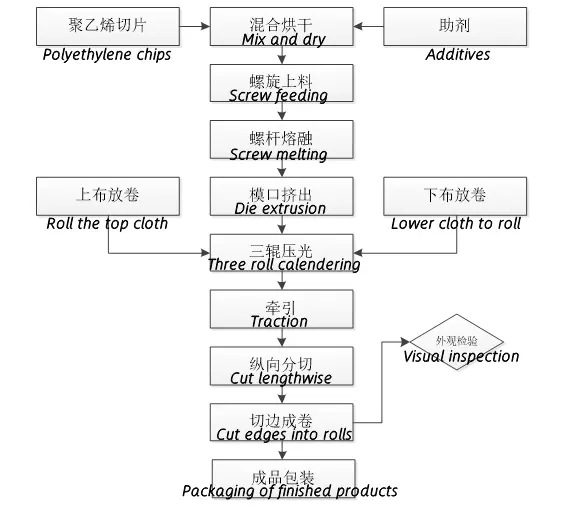

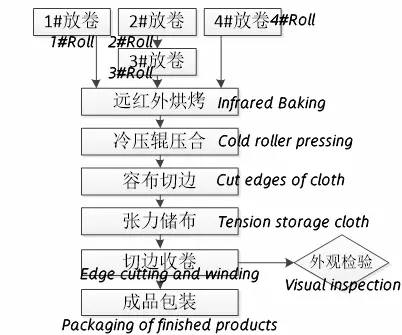

Manufacturing process: The manufacturing process of composite geomembranes involves combining different materials to achieve the desired performance and effect. Common composite methods include pressure-sensitive composite, coating composite, hot pressing composite, etc. The commonly used processes in our company are pressure-sensitive composite and hot pressing composite. The specific process is shown in the following figure:

Performance characteristics: Composite geomembranes have a variety of excellent performance characteristics, including high strength, high durability, high waterproofness, and high impermeability. In addition, it also has the advantages of light weight, ease of construction, and environmental protection.

Advantages: composite geomembranes have many advantages, such as improving engineering efficiency, reducing costs, and extending the life of the project.

II.The main specifications of composite geomembranes are as follows:

Material: The raw material of composite geomembrane is mostly polyethylene.

Thickness: The thickness of composite geomembranes varies depending on engineering requirements and material types. Generally, the thickness ranges from 2mm to 6mm, depending on the required load-bearing capacity and durability.

Width: The width of composite geomembranes is also designed according to the needs of the project. The common width is 3m-6m, which can be selected according to the construction conditions and actual needs.

Specifications

The specific specifications are as follows:

Technical specification of compound geomembrane(GB/T17642-2008)

( table I)

I t e m | Value | ||||||||

1 | (KN/m)≥Breaking strength(MD/CD) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 |

2 | %Breaking elongation | 30~100 | |||||||

3 | KN ≥CBR Bursting Strength KN/m | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | 3.2 |

4 | KN≥Tear strength | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.62 | 0.7 |

5 | MpaHydraulic pressure | As table Ⅱ | |||||||

6 | (N/cm)≥Peel strength | 6 | |||||||

7 | (cm/s)Vertical permeability coefficient | According to request | |||||||

8 | Width Variation | -1 | |||||||

(table Ⅱ)

Item | mm(Thickness of geomembrane) | ||||||||

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | ||

MPaHydraulic pressure | (Geotextile+Geomembrene) | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 |

(Geotextile+Geomembrene+Geotextile) | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | |

Company Advantages

Advanced Technology: Haoyang boasts China’s leading composite film production lines with high automation, precise process control, and superior product quality.

Certified Excellence: ISO 9001, ISO 14001, OHSAS 18001, and CQC certifications validate our commitment to quality, safety, and environmental sustainability.

Innovative R&D: Backed by a professional technical team with three invention patents and 32 utility model patents, we continually drive innovation in geosynthetic materials.

Industry Recognition: Acknowledged as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory," Haoyang sets benchmarks in the industry.

Global Reach: With comprehensive service and tailored solutions, Haoyang supports diverse environmental and engineering projects worldwide.

To learn more about our Composite Geomembrane Materials or to place an order, please contact us.

633.webp)

316.webp)

992.webp)

855.webp)