Non-woven geotextile introduction

Main features

High strength: the non-woven geotextile has a high tensile strength and elongation rate, which can meet the requirements of various engineering projects for material strength.

Excellent water permeability: due to its unique production process, the non-woven geotextile has a good water permeability, which can effectively maintain the stability of the soil.

Strong weather resistance: the non-woven geotextile has good high temperature resistance and freezing resistance, and can maintain stable performance in extreme climate conditions.

Corrosion resistance: non-woven geotextile has excellent resistance to acid, alkali and other chemical substances, which is suitable for various chemical environments.

Specification information

Nonwoven geotextile is generally 1-6 m wide, and its length is 50-100 m. This dimensional design makes the non-woven geotextile easy to lay and use in engineering.

Application area

Highway construction: the non-woven geotextile can prevent the water flow from washing away the soil, avoid the uneven settlement of the foundation, and improve the stability and service life of the highway.

Pavement repair: in the road repair, non-woven geotextile can repair the cracks to prevent the generation and expansion of road cracks.

Subway tunnel drainage: the non-woven geotextile can be used as the drainage material of the subway tunnel, using the advantages of its penetration and drainage, to keep the tunnel dry and stable.

Isolation layer: the non-woven geotextile can be used as an isolation layer to isolate different materials to prevent mixed layers and maintain the stability and safety of the project.

Other information

Non-woven geotextile also has good ventilation, filtration, heat preservation, water absorption, waterproof, expansion and other characteristics, making it is widely used in various engineering fields. At the same time, the price of non-woven geotextile is relatively low, fast production speed, can be produced in large quantities, is an efficient, practical engineering material.

Filament non-woven geotextile introduction

Definition

Filament geotextile is a kind of high strength and high density geotextile material, which is made of glass fiber, steel wire and polyester fiber through warp knitting technology. It does not contain chemical additives, and also does not undergo heat treatment, it is an environmentally friendly building material.

characteristic

High strength: filament non-woven geotextile has a high tensile strength and elongation rate because it is made of polymer materials such as polyester or polypropylene.

Corrosion resistance: in different acidity of soil and water.

Good water permeability: there is a gap between the fibers, so there is a good water seepage performance.

Good microbial resistance: to microorganisms, moth are not damaged.

Convenient construction: because the material is light, soft, so the transportation, laying, construction is convenient.

Complete specifications: the width of up to 9 meters, different specifications can be customized according to the engineering requirements.

Act on

Isolation: to isolate the building materials with different physical properties, so that two or more materials are not lost or mixed together, and that the overall structure and function of the materials are maintained.

Filtration (reverse filtration): when the water flows into the coarse soil layer from the fine soil layer, using the polyester staple fiber needle prick geotextile good air permeability and water permeability, so that the water flow through, and effectively intercept the flowing soil particles, fine sand, small stone, etc., to maintain the stability of water and soil engineering.

Drainage: with good water diversion performance, can form a drainage channel inside the soil, the excess liquid and gas in the soil structure discharge.

Reinforcement: enhance the tensile strength and deformation resistance of the soil, enhance the stability of the building structure, to improve the quality of the soil.

Protection: to prevent the water flow from scouring the soil, effectively concentrated stress diffusion, transfer or decomposition, to prevent the soil damage by external forces.

Application area

Highway and railway construction: used for drainage and reinforcement of geotextile.

Embankment and bridge engineering: geotextiles for embankment reinforcement, geotextiles for bridge engineering.

Underground drainage and irrigation: used for soil penetration ditch.

Soil or water applications: to provide protection and erosion protection.

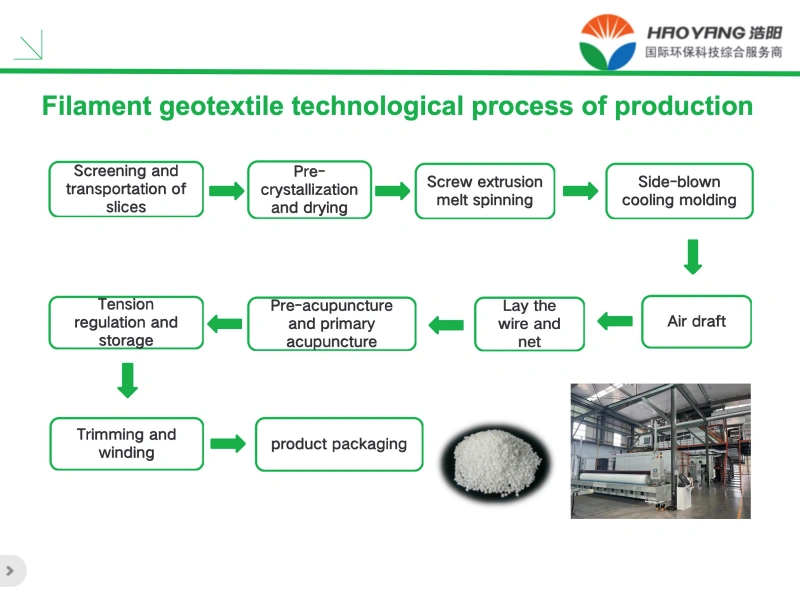

Introduction to Manufacturing Sequences

Sum up

Filament geotextile plays an important role in civil engineering with its high strength, corrosion resistance, good water permeability and good microbial resistance.

Short fiber non-woven geotextile introduction

Short-staple non-woven geotextile is a material commonly used in the field of civil engineering and environmental protection. It is composed of short fibers and non-woven fabrics, and has excellent physical properties and environmental adaptability. Short fiber non-woven geotextile plays a vital role in civil engineering, which is mainly used to enhance the soil stability and erosion resistance.

Main features

Enhance soil stability: the staple fiber non-woven geotextile significantly improves the stability of the soil and prevents soil landslide and collapse by increasing the tensile strength and shear strength of the soil.

Strong scour resistance ability: the material can effectively reduce soil erosion and erosion, and protect the quality of soil and water. Good water permeability and air permeability: the staple fiber non-woven geotextile allows water and air to pass through, maintaining the humidity and ventilation of the soil, which is conducive to plant growth and soil maintenance.

Prevent weed growth: it can also prevent weed growth in the soil and reduce the cost of weed management in farmland.

Application area

Civil engineering: for subgrade reinforcement of highway, railway and airport to prevent subsidence and deformation of pavement.

River channel and coastal protection: in the protection of river channel and coastline, the staple fiber non-woven geotextile can effectively prevent the erosion and erosion of water flow.

Land reclamation and environmental protection: used for land reclamation and environmental protection projects to improve soil quality and protect the ecological environment.

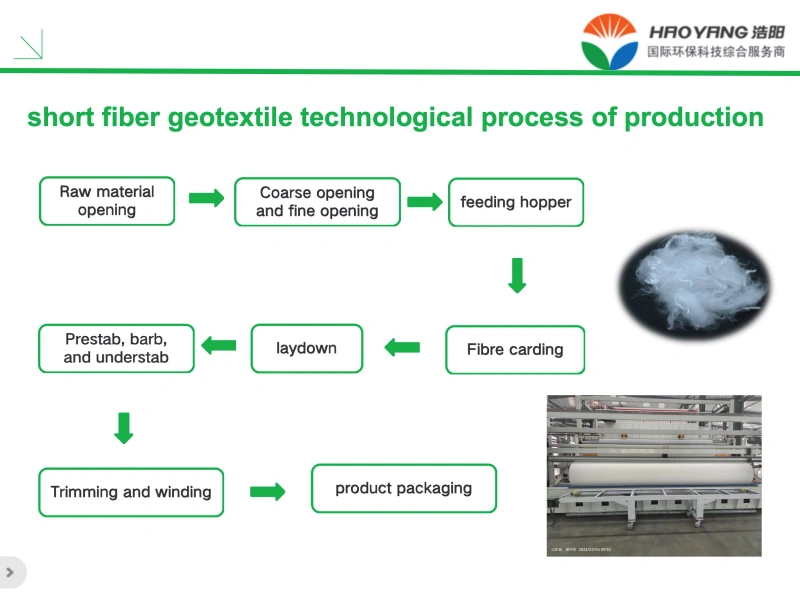

Introduction to Manufacturing Sequences

Sum up

Short fiber non-woven geotextile is an important civil engineering material, and its unique physical properties and environmental adaptability make it have a wide application prospect in land development, environmental protection and farmland management. Choosing high quality staple fiber non-woven geotextile can improve the quality and efficiency of the project and protect the health of soil and ecological environment.

About the comparison of staple fiber non-woven geotextile and filament non-woven geotextile, I will elaborate on the following aspects:

Material structure and composition

Short fiber non-woven geotextile: made of polyester or polypropylene and other short fiber randomly distributed in the substrate, fixed by thermal pressure or chemical adhesive, its structure is relatively loose, the overall strength is low.

filament geotextile: mainly composed of continuous long fiber woven, forming a stable interwoven structure between the fibers, with high overall strength and tensile properties.

Performance characteristics

Short-fiber non-woven geotextile fabric:

Good permeability and filtration performance, which can effectively prevent the loss and erosion of soil particles.

High strength, corrosion resistance, aging resistance and excellent filtration performance.

Technical requirements include tensile strength, plane shear strength, tear strength and other indicators to meet the relevant requirements, and require a long service life and a certain corrosion resistance.

Filament non-woven geotextile:

High tensile strength and elongation, can withstand large tension and deformation, suitable for bearing large load and deformation occasions.

High strength, high density, and has anti-skid and anti-shift, anti-corrosion and wear resistance and other excellent performance.

The performance indexes mainly include tensile strength, elongation rate, trapezoidal tear strength, burst strength, puncture strength, vertical permeability coefficient, etc.

Application scenarios

Short fiber non-woven geotextile: widely used in water conservancy engineering, highway and railway, environmental and other engineering and other fields of drainage, isolation, filtration and reinforcement, to ensure the normal operation and service life of the project.

filament geotextile: often used in bank embankment, slope protection, earth and rock mound stability and other projects, suitable for embankment, bank slope, bank protection and other projects in the reinforcement and protection structure, to improve the stability and durability of the project.

Production process and cost

Short fiber non-woven geotextile: the production process is relatively simple, the cost is low, so the market price is relatively low.

filament geotextile: the production process is relatively complex, the cost is high, so the market price is relatively high.

Sum up

There are significant differences in material structure, performance, application scenario, and production process and cost. It requires drainage and filtration, and its high strength and good extensibility for high load and deformation. In the selection, it should be comprehensively considered comprehensively according to the needs and conditions of the specific project.

Case

On the importance of geotextiles in landfills

The application of landfill geotextile in landfill sites is very important. Its main functions include the following aspects:

● Anti-penetration

Geotextile can effectively prevent harmful substances and liquids from infiltrating into the soil and groundwater, thus avoiding pollution to the environment.

● Protect

Geotextile can effectively prevent the landfill from producing odor and smell, thus protecting the surrounding environment and people's quality of life.

● Reinforce

Geotextile can effectively reinforce the bottom and top of the landfill, and enhance the stability and durability of the landfill.

Why Choose Our Non-Woven Geotextiles?

Our company offers high-quality non-woven geotextiles (Filament, Short Fiber, and Beyond) that meet stringent industry standards. Our products are engineered to provide superior performance and durability, ensuring the success of your construction and environmental projects. We offer a range of options tailored to specific project requirements, backed by competitive pricing and exceptional customer service.

Contact Us

For more information about our non-woven geotextiles and how they can benefit your projects, please contact us. Our expert team is ready to assist you in selecting the right products to achieve optimal results.

897.webp)

942.webp)

237.webp)