Factors Influencing the Price of Geomembrane and Its Relationship with Specification

Geomembrane, as an essential engineering material, has found widespread applications in water conservancy projects, environmental protection projects, and other fields. Its price is influenced by various factors, including raw materials, specifications, production and processing costs, transportation expenses, and market demand. Among these, the specifications of geomembrane, particularly its size, thickness, and performance level, have a significant impact on its price.

(Resident Geomembrane)

Firstly, raw materials are one of the crucial factors determining the price of geomembrane. Geomembrane is typically composed of plastic film and HDPE geomembrane. The quality of the raw materials directly affects the quality and price of the geomembrane. For instance, high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polyvinyl chloride (PVC) are common plastics used in geomembrane manufacturing. HDPE is often preferred for its superior strength, durability, and resistance to environmental factors. However, it tends to be more expensive compared to LDPE or PVC. According to industry reports, the cost per square meter of HDPE geomembrane can range from $1.50 to $3.00, depending on factors such as thickness and UV stabilization. High-quality geomembrane often uses imported materials, thus resulting in a higher price.

233482.webp)

(white HDPE geomembrane 1.5mm)

Secondly, the specifications of geomembrane play a significant role in determining its price. Factors such as size, thickness, and performance level all contribute to the pricing of geomembrane. Larger sizes and thicker thicknesses require more raw materials and higher production costs, leading to higher prices. A 10m x 10m geomembrane with a thickness of 1.5mm might have a lower price per square meter compared to a 20m x 20m geomembrane with a thickness of 2mm. The increased size and thickness contribute to the higher overall cost of the latter. Higher-performance geomembrane, with its superior durability and anti-aging properties, also commands a higher price.

(black HDPE geomembrane 1.5mm)

In addition, factors such as production and processing costs, transportation expenses, and market demand also influence the price of geomembrane. Production and processing costs encompass labor, utility expenses, and other overheads. Transportation expenses are related to the distance and quantity of the geomembrane being transported. When market demand increases, the price of geomembrane tends to rise; conversely, when demand decreases, prices may fall.

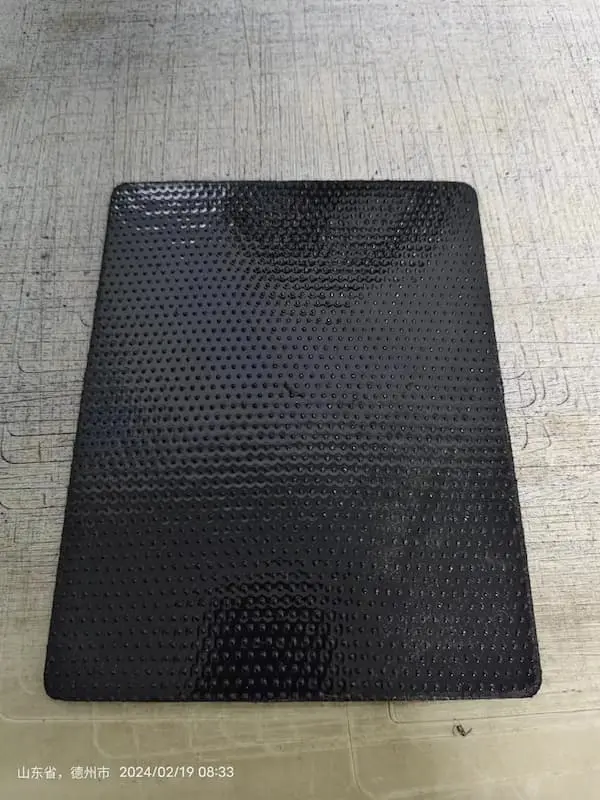

(black double faced textured geomembrane)

In conclusion, the price of geomembrane is influenced by a combination of multiple factors. When selecting geomembrane, it is essential to consider factors such as specifications, raw materials, production and processing costs, transportation expenses, and market demand to choose a cost-effective product. Furthermore, it is crucial to select appropriate specifications and performance levels based on specific engineering requirements to ensure that the geomembrane meets the engineering standards, enhancing the quality and efficiency of the project.

256.webp)

503.webp)

759.webp)

897.webp)

942.webp)

237.webp)