What is Geosynthetic Clay Line

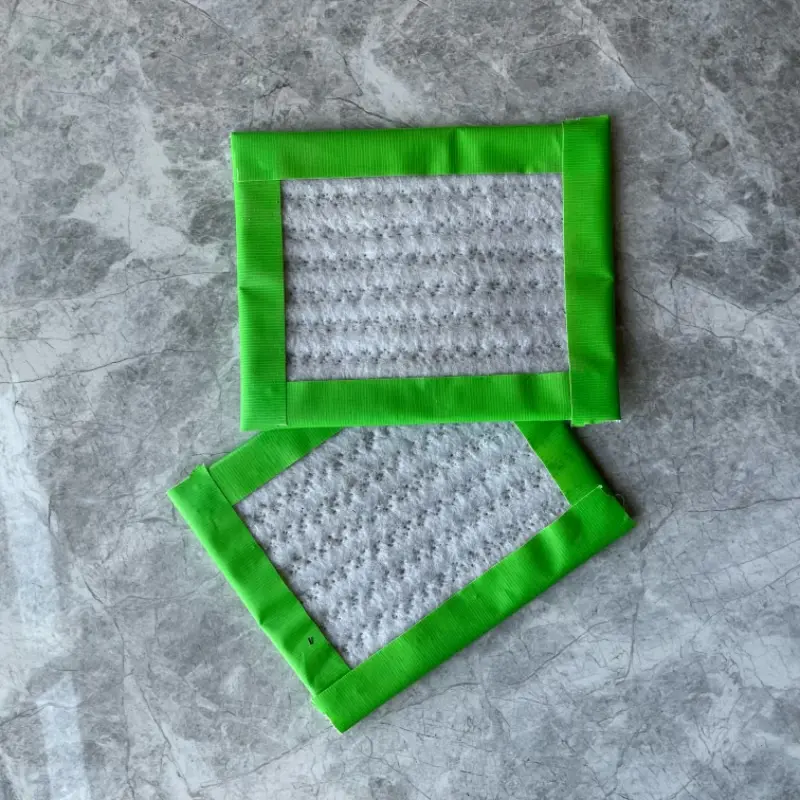

Geosynthetic Clay Liner (GCL), also known as a sodium bentonite composite waterproof pad, is designed by filling high-swelling sodium bentonite between special composite geotextile and non-woven fabric. The impermeable cushion, created using an acupuncture method, forms numerous small fiber spaces, preventing the flow of bentonite particles in one direction. When exposed to water, it creates a uniformly high-density colloidal waterproof layer within the pad, effectively preventing water leakage. GCL finds application in various areas, including artificial lakes, landfills, underground garages, roof gardens, pools, oil depots, and chemical yards.

Performance features

1, Impermeability: GCLs provide excellent impermeability due to the swelling nature of sodium bentonite, forming a tight waterproof barrier when in contact with water.

2, Sealing Capability: The ability of GCLs to swell and form a colloidal waterproof layer enhances their sealing capability, preventing water from permeating through the liner.

3, Flexibility: GCLs are flexible and conform to the contours of the underlying surface, making them suitable for different shapes and profiles in various construction projects.

4, Chemical Resistance: GCLs exhibit resistance to a wide range of chemicals, making them suitable for applications in environments with different types of contaminants.

5, Ease of Installation: The installation process of GCLs is relatively simple compared to traditional clay liners. This can result in cost savings and faster project completion.

Factors Affecting Geosynthetic Clay Liner Price:

1, Material Quality: The quality of the clay and geotextile components significantly influences the price of GCLs. Higher quality materials may come at a premium but offer enhanced performance and longevity, reducing long-term maintenance costs.

2, Thickness and Size: Thicker GCLs typically command higher prices due to increased material usage. Similarly, larger liner sizes required for expansive projects contribute to higher costs.

3, Manufacturing Technology: Advanced manufacturing processes and technologies used in producing GCLs can affect their price. Innovations such as improved bonding techniques and enhanced composite materials may result in higher upfront costs but can offer superior performance and durability.

4, Supplier and Location: The choice of supplier and their geographical location can impact GCL prices. Suppliers with proximity to project sites may offer competitive pricing due to reduced transportation costs.

5, Certifications and Compliance: GCLs meeting specific industry standards and certifications may be priced higher due to the additional costs associated with compliance testing and quality assurance.

6, Installation Complexity: Projects with challenging site conditions or intricate installation requirements may incur higher labor and equipment costs, thus influencing the overall price of GCL installation.

By considering these factors, purchasers can better understand the pricing dynamics of geosynthetic clay liners and make informed decisions when sourcing these materials for their geotechnical or environmental projects.

Factors Influencing Price | Potential Price Range |

Per Square Meter (or Square Foot) Pricing | $5 - $15 per square meter |

Bulk Pricing | Discounts for larger quantities |

Quality and Features | Higher-quality and feature-rich liners may command higher prices |

Shipping and Handling | Additional costs for transportation, handling, and any import/export fees |

Market Demand | Prices may vary based on demand fluctuations |

Geographical Location | Prices may vary based on proximity to manufacturing facilities and shipping costs |

The Value Proposition of Geosynthetic Clay Liners:

1, Environmental Protection: GCLs play a crucial role in environmental protection by preventing the migration of contaminants into soil and groundwater. Investing in high-quality GCLs ensures long-term environmental sustainability and compliance with regulatory standards.

2, Cost Savings: Although initial costs may be higher, the long-term benefits of using GCLs outweigh the upfront investment. By mitigating the risk of leakage and contamination, GCLs reduce the potential for costly remediation efforts and regulatory fines.

3, Durability and Performance: Premium GCLs offer excellent durability and performance, providing reliable containment solutions for a wide range of applications. Their resistance to chemical and physical degradation ensures prolonged service life and minimal maintenance requirements.

4, Versatility: Geosynthetic clay liners are versatile and adaptable to various site conditions and project requirements. Whether used in landfill liners, mining operations, or hydraulic engineering projects, GCLs offer reliable performance and ease of installation.

5, Regulatory Compliance: Compliance with environmental regulations and industry standards is paramount in modern construction and engineering projects. GCLs meeting stringent regulatory requirements provide peace of mind to project stakeholders and ensure legal compliance throughout the project lifecycle.

In conclusion, while the price of geosynthetic clay liners may vary depending on several factors, their value proposition extends beyond upfront costs. Investing in high-quality GCLs offers long-term benefits in terms of environmental protection, cost savings, durability, and regulatory compliance. By understanding the factors influencing GCL prices and evaluating the value they provide, project planners can make informed decisions to achieve optimal outcomes in their engineering and environmental projects.

494.webp)

220130.webp)

897.webp)

942.webp)

237.webp)