What is Geocomposite Drainage net?

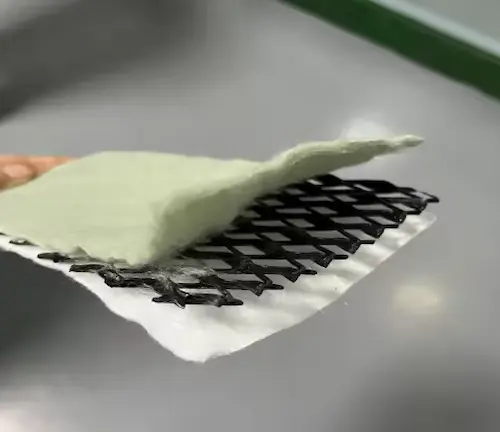

A geocomposite drainage net is a type of geosynthetic material that combines multiple components, such as geotextiles, geonets, and drainage cores, to provide an efficient solution for managing water flow in construction projects. These drainage nets are designed to facilitate the quick movement of water while preventing soil erosion, controlling groundwater, and reducing hydrostatic pressure against structures.

Typically, a geocomposite drainage net is constructed by bonding a geotextile fabric to a drainage core, which is often made of a plastic or polymer material like high-density polyethylene (HDPE). The geotextile fabric acts as a filtration medium, allowing water to pass through while preventing soil particles from clogging the drainage system. The drainage core, on the other hand, is responsible for directing the water to appropriate outlets.

Types of Geocomposite Drainage Net

Geocomposite drainage nets come in various types, each designed for specific applications and environments.

1. High-Density Polyethylene (HDPE) Core Composites

•Material: HDPE core with non-woven geotextile layers.

•Application: Ideal for road construction, landfill liners, and retaining walls.

•Advantages: High tensile strength, excellent chemical resistance, and long service life.

2. Polypropylene (PP) Core Geocomposites

•Material: PP core with woven or non-woven geotextile layers.

•Application: Suitable for slope stabilization, foundation drainage, and erosion control.

•Advantages: Lightweight, flexible, and cost-effective.

3. Biaxially Oriented Polypropylene (BOPP) Core Geocomposites

•Material: BOPP core with non-woven geotextile layers.

•Application: Commonly used in tunnel linings, bridge abutments, and embankments.

•Advantages: Enhanced mechanical properties, improved dimensional stability, and superior filtration capabilities.

Advantages of Geocomposite Drainage Net

1. Efficient Water Management

•The core layer channels water efficiently, preventing water accumulation and reducing the risk of water-related damage.

2. Soil Stabilization

•The geotextile layers filter soil particles, preventing clogging and maintaining the integrity of the drainage system.

3. Cost-Effective

•Compared to traditional drainage solutions, geocomposite drainage nets offer a more cost-effective and durable option. By reducing the need for extensive maintenance and repairs, geocomposite drainage nets offer significant cost savings over the life of a project.

4. Environmental Benefits

•By preventing waterlogging and soil erosion, geocomposite drainage nets help to protect the environment and reduce the need for frequent maintenance. These nets help in preventing soil erosion and protecting groundwater, contributing to environmental sustainability.

5. Versatility

•These materials can be used in a wide range of construction applications, making them a versatile solution for various projects.

6. Ease of Installation:

Geocomposite drainage nets are lightweight and flexible, making them easy to handle and install. They can be cut to size and laid out quickly, reducing construction time and labor costs.

Applications of Geocomposite Drainage Net

1. Roadways and Railway Construction

In road and railway construction, proper drainage is essential to maintain the integrity of the structure and prevent water-related damage. Geotextile drainage nets are often used to manage the flow of water beneath roads and railways, especially in areas with high groundwater levels or poor drainage conditions. The nets are placed between the subgrade and the road surface or railway ballast to allow water to pass through, preventing water accumulation and minimizing the risk of pavement or track settlement.

In railway embankments, geotextile drainage nets help control the flow of water and prevent the formation of pockets of water beneath the tracks. This is crucial to prevent track instability, which could lead to derailments or other safety issues.

2.Tunnel and Underground Construction

In the construction of retaining walls, water accumulation behind the structure can create significant pressure, leading to potential structural failure. Geocomposite drainage nets are used to provide drainage behind retaining walls, relieving hydrostatic pressure and preventing water buildup. The drainage net allows water to flow freely, reducing the risk of wall deformation and improving the stability of the structure.

3. Retaining Walls and Slope Stabilization

Geotextile drainage nets are widely used in the construction of retaining walls, particularly in areas with high water content or where groundwater flow needs to be controlled. The drainage system behind the retaining wall prevents the accumulation of water, which could increase the hydrostatic pressure against the wall and cause structural failure. By providing a pathway for water to flow away from the wall, geotextile drainage nets help maintain the stability of the structure.

Similarly, in slope stabilization projects, these drainage systems are employed to manage water flow through the soil, reducing the likelihood of landslides or slope failures. They are particularly useful in mountainous or hilly terrain where water accumulation can weaken soil and lead to erosion.

4. Sports Fields Construction and Landscaping

In landscaping projects, particularly in the construction of sports fields or parks, geotextile drainage nets are used to manage water flow and prevent waterlogging. These drainage systems are installed beneath the surface layer of sports fields or green areas to ensure that excess water is effectively drained away, preventing damage to the turf or soil compaction. This is particularly important for fields with high traffic, such as football or baseball fields, where good drainage ensures optimal playing conditions.

5. Channel Linings:

Geocomposite drainage nets are used to line channels and ditches to prevent erosion and ensure efficient water flow. They are particularly useful in agricultural and irrigation systems.

Best Practices for Installation

1. Site Preparation

•Ensure the site is properly graded and compacted to provide a stable base for the geocomposite. Smooth out any uneven surfaces to create a stable base.

2. Handling and Storage

•Store the geocomposite in a dry, shaded area to prevent degradation and damage.

3. Laying the Material

•Unroll the geocomposite carefully, avoiding wrinkles and folds. Overlap the edges by at least 100 mm to ensure a continuous drainage path.

4. Securing the Material

•Use anchor pins or stakes to secure the net in place, especially in areas with high water flow. Ensure the pins are placed at regular intervals to maintain the net's stability.

5. Backfilling and Compaction

•After laying the net, backfill with appropriate materials such as gravel or sand. Compact the backfill material to ensure it is dense and stable.

6. Inspection and Maintenance

•Regularly inspect the installed geocomposite for signs of damage or clogging. Perform necessary maintenance to ensure optimal performance.

Standards and Testing

To ensure the quality and performance of geocomposite drainage nets, several standards and testing methods have been established:

1. ASTM D5544: This standard test method determines the thickness of geocomposites, which is crucial for assessing their structural integrity and drainage capacity.

2. ISO 12958: This international standard specifies the method for determining the permeability of geosynthetics under constant head conditions, ensuring that the nets can effectively manage water flow.

3. EN ISO 12958: This European standard provides guidelines for testing the permeability of geosynthetics, ensuring compliance with regional regulations and standards.

4. FHWA HRT-19-001: The Federal Highway Administration (FHWA) has published best practices for using geosynthetic reinforcement in roadways, including guidelines for the installation and maintenance of geocomposite drainage nets.

Future Trends and Innovations

1. Smart Geocomposites:

Researchers are developing smart geocomposite drainage nets that can monitor water flow and soil conditions in real-time. These nets are equipped with sensors and can send data to a central monitoring system, allowing for proactive maintenance and management.

2. Biodegradable Materials:

There is growing interest in using biodegradable materials for geocomposite drainage nets to reduce environmental impact. These materials break down naturally over time, minimizing waste and promoting sustainability.

3. Nanotechnology:

Advances in nanotechnology are leading to the development of geocomposite drainage nets with enhanced properties such as increased strength, improved filtration, and better chemical resistance.

4. Recycled Materials:

Using recycled materials in the production of geocomposite drainage nets is becoming increasingly popular. This not only reduces the carbon footprint but also helps in conserving natural resources.

Conclusion

Geocomposite drainage nets are a vital component in modern construction, offering a range of benefits from efficient water management to environmental protection. Their versatility and durability make them suitable for a wide array of applications, from road construction to landfill liners. By following best practices for installation and maintenance, professionals can ensure the optimal performance and longevity of these advanced materials. As the demand for sustainable and cost-effective construction solutions continues to grow, geocomposite drainage nets will undoubtedly play a crucial role in meeting these needs.

897.webp)

942.webp)

237.webp)