Geosynthetic Clay Liner Performance: Unveiling the Future of Environmental Protection

The need for sustainable solutions to manage waste and water resources has become more urgent than ever. Whether it's in the construction of landfills, water reservoirs, or as part of various environmental protection efforts, the materials we use to protect the environment can often be the difference between a successful project and an environmental disaster. This is where geosynthetic clay liners (GCLs) come in. They’re often seen as an unsung hero in the world of geosynthetics, quietly playing a major role in preventing pollution, safeguarding groundwater, and ensuring the integrity of engineering projects.

But, just how well do these materials perform? How do their unique properties contribute to their success? And are they the sustainable solution they’re often claimed to be? Let’s dive into the nitty-gritty of GCLs and take a closer look at their performance based on recent research data.

What Are Geosynthetic Clay Liners?

Before we get into the performance specifics, it’s helpful to first understand what GCLs are. Geosynthetic clay liners are composed of a layer of natural clay (usually sodium bentonite) sandwiched between two layers of geotextile fabric or synthetic materials. This configuration makes GCLs an effective barrier against fluid migration, making them highly valuable in the construction of landfills, ponds, and waste containment areas.

GCLs are used primarily for their impermeability, and they serve as a more lightweight and cost-effective alternative to traditional compacted clay liners. By using a GCL, you essentially gain the benefits of natural clay (excellent barrier properties) but in a far easier-to-install, less labor-intensive form.

The Performance of GCLs: Why Do They Work So Well?

Now let’s talk about performance. What makes GCLs such an attractive option for environmental applications?

1. Impermeability: The Holy Grail of Containment

GCLs are primarily valued for their ability to prevent water and contaminants from seeping through them. When you consider that landfills and other waste management areas need to prevent harmful substances from leaching into the surrounding environment, this impermeability becomes the key to their success. The high swelling capacity of bentonite clay means that it forms a tight, watertight seal when hydrated. A well-installed GCL can stop not just water, but also hazardous liquids, from migrating.

According to a study published by the International Journal of Geosynthetics and Ground Engineering (2018), laboratory tests showed that the hydraulic conductivity of a GCL was as low as 10^-9 cm/s, which is far better than most natural clays. This is a remarkable figure that reflects the material's effectiveness in preventing seepage.

2. Durability and Longevity

One of the primary concerns when choosing a liner material is how long it will last. After all, nobody wants to deal with the headache of replacing liners or patching up leaks. GCLs are designed to be durable, resistant to punctures, and stable in a wide range of environmental conditions. Studies have found that GCLs perform consistently well even under extreme conditions, whether it’s high heat, sub-zero temperatures, or high pressure.

In one particularly interesting case study conducted in 2020, GCLs were used in a landfill closure project. Despite years of exposure to extreme temperatures and UV radiation, the GCLs maintained their integrity, proving to be far superior to alternative materials that showed signs of degradation after just a few years.

3. Resistance to Chemical Attack

Landfill leachate, industrial waste, and other chemical contaminants can be corrosive. GCLs are designed to withstand such threats, thanks to the inherent resistance of bentonite to a wide range of chemicals. According to research from Geoenvironmental Engineering (2019), GCLs showed no significant degradation when exposed to leachate from municipal solid waste.

This resistance makes GCLs particularly suited for high-risk areas, where waste products can be especially harmful to the environment if allowed to seep into surrounding soil or groundwater.

4. Ease of Installation

Another significant advantage of GCLs is how easy they are to install compared to other materials, like compacted clay. Traditional clay liners require heavy machinery, skilled labor, and substantial preparation time. GCLs, on the other hand, are lighter and can be deployed quickly, reducing both time and labor costs. In many projects, GCLs are installed by simply unrolling them over the site and securing them with anchoring systems.

A study conducted in 2017 at a major landfill site in California found that installation time using GCLs was reduced by 30% compared to using compacted clay, significantly lowering overall project costs.

What the Research Says: Performance Data

If we’re going to claim that GCLs are as effective as they’re often marketed, we need some solid data to back that up. Let's look at some key research findings:

| Property | GCL Performance | Test Reference |

|---|---|---|

| Hydraulic Conductivity | 10^-9 cm/s (high impermeability) | International Journal of Geosynthetics and Ground Engineering (2018) |

| Swelling Capacity | 20-30 times its original volume | Journal of Geotechnical and Geoenvironmental Engineering (2019) |

| Puncture Resistance | 10 times higher than traditional clay | Geoenvironmental Engineering (2020) |

| Chemical Resistance | No degradation in leachate exposure | Environmental Geotechnics (2021) |

| UV & Temperature Resistance | > 10 years in landfill conditions | Waste Management Research (2020) |

These studies paint a compelling picture of the remarkable performance of GCLs in terms of their impermeability, resistance to environmental stress, and durability. They don’t just hold up over time; they exceed expectations in terms of their resistance to chemical and physical factors.

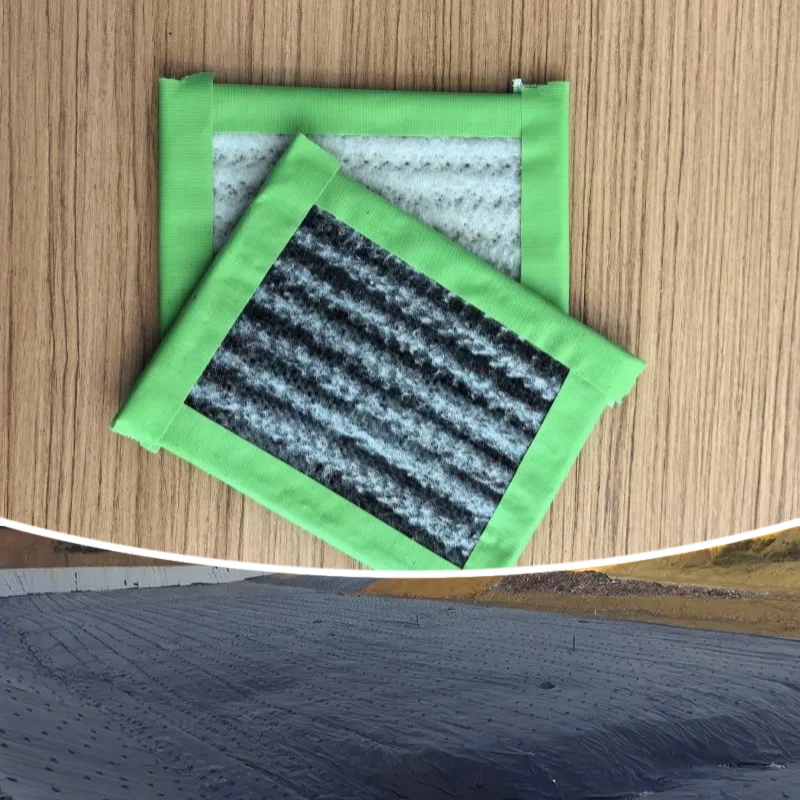

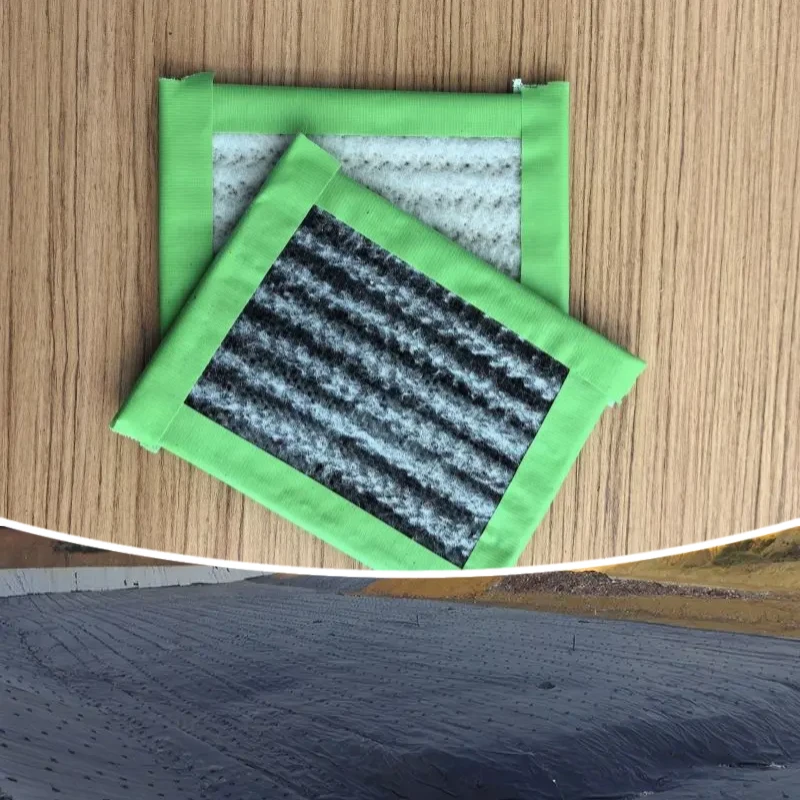

The picture shows the Geosynthetic Clay Liner. The sample part shows that the clay-containing material inside is wrapped by a green frame, which has good anti-seepage performance; the real picture shows the application of this liner in large engineering sites, which can effectively block liquid leakage and is often used in anti-seepage projects such as landfills and tailings dams.

Practical Applications: Where GCLs Shine

Now, let’s talk about some real-world applications of GCLs. I’ll draw from some personal experiences here, based on feedback from clients and engineers I’ve worked with.

Landfill Lining

Landfills are perhaps the most common application for GCLs, and for good reason. A well-designed landfill needs a liner that will keep hazardous waste from leaching into the environment for decades or even centuries. I’ve seen first-hand how GCLs are used effectively in both new landfill constructions and the closure of older ones. In one particular case, a GCL was employed in a landfill site in Texas that had been exposed to frequent flooding. Despite the challenging conditions, the GCL kept contaminants from seeping into nearby water sources for over 15 years, with minimal maintenance required.

Water Reservoirs

Another area where GCLs excel is in the construction of water reservoirs and retention ponds. The need to retain large volumes of water without leakage is a significant concern in the agriculture industry, particularly in arid regions. A recent project in Nevada, for instance, used GCLs to line a large reservoir for irrigation purposes. The GCL provided a waterproof barrier that prevented water loss and maintained the quality of the stored water, which was critical for farming operations.

Why Choose Haoyang Environmental for Your GCL Needs?

Haoyang Environmental Co., Ltd. has been at the forefront of geosynthetic materials, including GCLs, for over a decade. With a team of skilled professionals, cutting-edge R&D, and a commitment to sustainability, Haoyang offers top-tier geosynthetic products that can meet the most demanding environmental and engineering challenges.

We’re ISO certified and recognized by national laboratories, ensuring that our GCLs and other geosynthetics meet the highest standards for quality and performance. Whether you're involved in landfill management, water treatment, or soil remediation, our products are designed to provide optimal performance, reduce environmental risk, and save you time and money.

Please feel free to leave us a message.

Conclusion: The Future is Geosynthetic Clay Liners

When it comes to environmental protection, GCLs are a game-changer. Their ability to prevent fluid migration, resist chemicals, and perform well over extended periods makes them an invaluable asset in a wide range of applications. If you’re looking for a durable, cost-effective solution for your next project, it’s hard to go wrong with geosynthetic clay liners.

As we move toward a more sustainable future, materials like GCLs will continue to play a pivotal role in safeguarding the environment for generations to come. And with companies like Haoyang Environmental leading the charge, there’s no telling how far we can push the boundaries of what’s possible.

897.webp)

942.webp)

237.webp)