Geosynthetic materials, a family of synthetic products engineered for use in civil engineering and environmental applications, play a crucial role in reinforcing and strengthening the performance of various infrastructure and environmental systems.

Projects need to strengthen

There are various types of engineering projects that require reinforcement, and the specific reinforcement needs depend on the nature of the project, environmental conditions, and design standards. Here are some types of projects that may require to strengthen:

1, Retaining Walls and Dams:

Reinforcement may be needed in flood embankments, dam construction, or other civil engineering projects to enhance stability, resistance to sliding, and erosion control.

2, Bridges and Supporting Structures:

Old bridges, large supporting structures, or structures damaged due to natural disasters, vehicle collisions, etc., may require reinforcement to ensure structural safety.

3, Buildings and Houses:

Old buildings, houses with significant cracks, or structures undergoing renovation may require reinforcement to improve seismic performance, structural stability, and overall safety.

4, Foundation Reinforcement:

In areas with weak soil or high settlement potential, foundation reinforcement is a common requirement to reduce building settlement and the risk of structural damage.

5, Rock Slopes and Excavation Slopes:

Rock slopes and excavation slopes may need reinforcement due to natural rockfall or excavation activities, to mitigate the risk of slope instability.

6, Tunnels and Underground Structures:

In underground structures such as tunnels and basements, reinforcement may be necessary to address geological challenges and ensure safety and stability.

7, Coastal Protection:

Coastal lines and embankments may need reinforcement to withstand erosion and damage caused by waves, tides, and storms.

Geosynthetic materials are used to strengthen

1, Composite geomembrane

A composite geosynthetic membrane is composed of geotextile and geomembrane, offering high strength and impermeability. It is lightweight, facilitating easy construction, and can be employed for both vertical and horizontal anti-seepage reinforcement in dam projects.

It exhibits excellent physical and mechanical properties, including high tear resistance, puncture resistance, and tensile strength, along with good elongation characteristics. Moreover, it is acid-alkali resistant, corrosion-resistant, durable against aging, and demonstrates superior anti-seepage performance.

How does the geosynthetic membrane play a role in reinforcement?

1), Waterproofing and Anti-seepage:

One of the primary functions of the composite geosynthetic membrane is to provide excellent waterproofing and anti-seepage performance. Comprising geotextile and geomembrane, it forms a robust waterproof layer, effectively preventing the infiltration of water into the soil and protecting engineering structures from water damage.

2), Soil Stability:

The composite geosynthetic membrane contributes to enhancing soil stability. With its robust tear resistance, puncture resistance, and superior tensile strength, it fortifies the soil's load-bearing capacity, reducing deformation and settlement caused by structural loading.

3), Reinforcement of Soil Structure:

Utilizing the composite geosynthetic membrane in dams and other soil structures reinforces the overall structure. It distributes loads, alleviates local stresses, improves the overall performance of the soil, and prevents uneven settlement due to loading.

the composite geosynthetic membrane serves as a crucial reinforcement in engineering, providing reliable protection for waterproofing, anti-seepage, and soil stability in diverse projects.

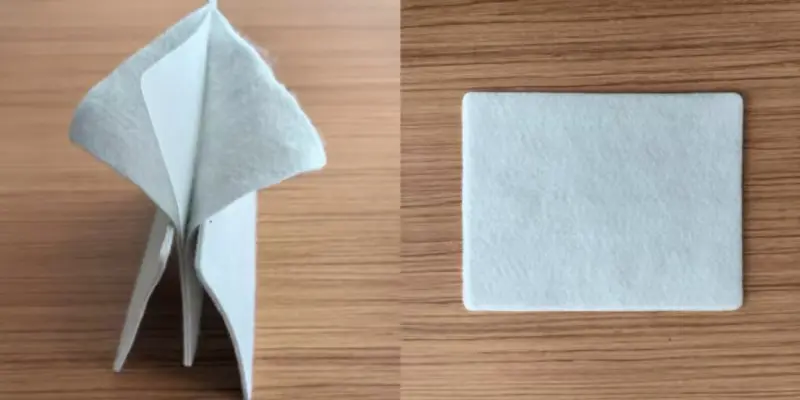

2, Geotextile fabrics

Geotextile fabrics, characterized by excellent filtration and water permeability, can be used for both vertical and horizontal anti-seepage reinforcement in many projects. Additionally, it serves the purpose of reinforcement and protection. HaoYang is capable of producing short-fiber needle-punched geotextile and polyester filament geotextile.

How does the geotextile fabrics play a role in reinforcement?

1), Anti-seepage:

Due to their excellent permeability and filtration characteristics, geotextile fabrics can prevent water infiltration into the soil. This makes them widely used in civil engineering for waterproofing and anti-seepage, protecting structures from water damage.

2), Soil Separation:

Geotextile fabrics can be employed to separate soils of different particle sizes and types, preventing them from mixing and permeating each other. This helps maintain the stability of the soil, preventing the mixing of different materials that could compromise soil structure.

3), Soil Reinforcement:

In loose or unstable soils, geotextile fabrics can enhance soil stability. By bonding with the soil, they disperse loads, reduce soil settlement and deformation, and enhance the overall load-bearing capacity.

4), Bank Protection and Flood Embankments:

Geotextile fabrics can be utilized to reinforce bank protection and flood embankments, enhancing their resistance to erosion and seepage, preventing water flow from eroding the soil.

In summary, geotextile fabrics play a significant reinforcing role in engineering through functions such as anti-seepage, soil separation, and soil reinforcement, contributing to increased stability and durability of engineering structures.

3, HDPE geomembrane

High-Density Polyethylene Geomembrane; High-Density Polyethylene Geomembrane, abbreviated as HDPE Geomembrane, is a polymer material known for its excellent anti-seepage performance and durability. It is utilized for anti-seepage reinforcement in engineering projects.

How does the HDPE geomembrane play a role in reinforcement?

The reinforcing role of HDPE geomembrane in engineering is primarily in the following aspects:

1), Anti-seepage Function:

HDPE geomembrane, renowned for its high-density polyethylene material, exhibits excellent anti-seepage performance. Widely utilized in various water, environmental, and infrastructure projects, it prevents water infiltration, safeguarding the integrity of soil structures.

2), Durability:

HDPE geomembrane possesses outstanding durability, maintaining its performance over an extended period. Therefore, in engineering projects requiring long-term use and high stability, it provides reliable reinforcement.

3), Adaptability:

Due to its flexibility and pliability, HDPE geomembrane demonstrates strong adaptability, making it suitable for diverse terrains and environmental conditions. This versatility allows it to effectively reinforce different types of engineering projects.

4), Soil Stability:

Application of HDPE geomembrane enhances soil stability, mitigating settlement and deformation. By forming a robust waterproof layer, it aids in load dispersion, improving the overall load-bearing capacity of the soil.

In a word, the reinforcing role of HDPE geomembrane in engineering is evident in aspects such as anti-seepage, enhanced soil stability, and durability, providing reliable protection and strengthening effects for engineering structures.

FAQ

1. What are geosynthetic materials used for strengthening?

Geosynthetic materials are commonly used to reinforce various civil engineering structures, such as embankments, retaining walls, and slopes. They include geotextiles, geogrids, geocells, and geomembranes, which offer properties like tensile strength, flexibility, and durability for enhancing soil stability and preventing erosion.

2. How do geosynthetic materials improve soil stability?

Geosynthetic materials reinforce soil stability by distributing loads, reducing localized stress concentrations, and improving the overall strength of the soil. They also prevent soil erosion and provide effective solutions for challenging soil conditions, contributing to enhanced stability of engineered structures.

3. What is the role of geosynthetic materials in preventing water seepage?

Geosynthetic materials, such as geomembranes and geotextiles, form impermeable barriers that prevent water seepage into the underlying soil. These materials enhance the anti-seepage properties of structures like dams, reservoirs, and landfills, protecting against water-induced damage.

4. Can geosynthetic materials be used in road construction?

Yes, geosynthetic materials play a crucial role in road construction. Geogrids and geotextiles are commonly used to reinforce road bases, providing additional strength and stability. They help control the development of cracks, reduce settlement, and enhance the overall performance and lifespan of road structures.

5. Are geosynthetic materials environmentally friendly?

Geosynthetic materials are designed to be environmentally friendly. Many are made from recyclable materials, and their use can lead to reduced environmental impact by minimizing the need for traditional construction materials. Properly selected and installed geosynthetic solutions can also contribute to sustainable and eco-friendly engineering practices.

897.webp)

942.webp)

237.webp)