Geosynthetic Reinforcement Retaining Walls: Innovative Solutions for Sustainable Infrastructure

The geosynthetic reinforcement retaining wall is a structure that utilizes geosynthetic materials to reinforce soil and enhance its load-bearing capacity and stability. It consists of several key components that work together to provide stability and durability to the wall.

Foundation: The foundation is the base of the retaining wall and is typically made of concrete, rocks, or other sturdy materials. It supports the weight of the entire wall and transfers the load to the ground.

Wall Structure: The wall structure is the main body of the retaining wall and is typically constructed using materials such as concrete, stones, or soil. The height and thickness of the wall are determined based on design requirements to ensure sufficient load-bearing capacity and stability.

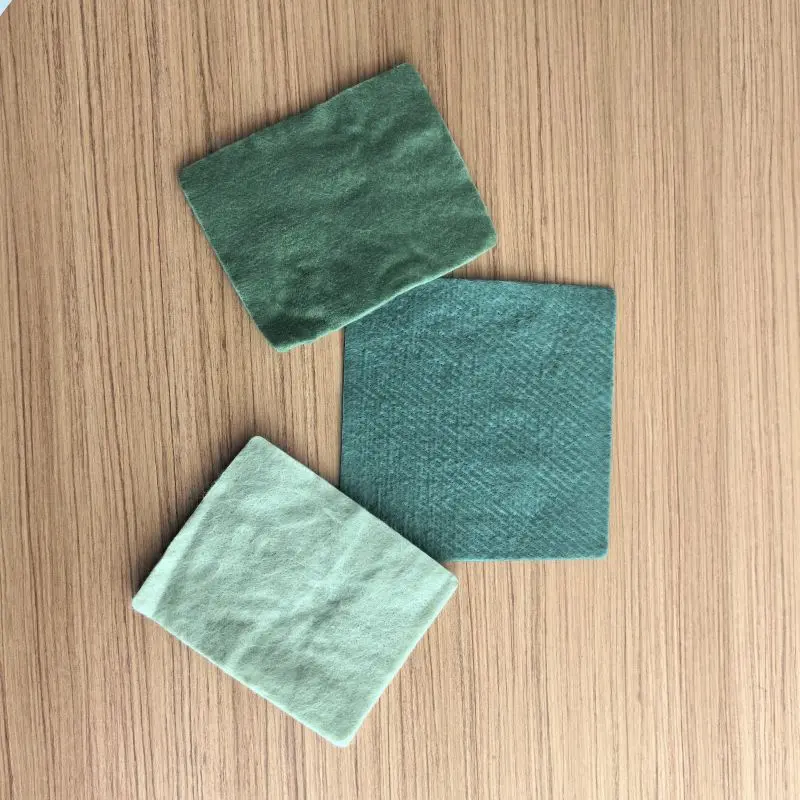

Geosynthetic Materials: Geosynthetic materials are artificial materials used to enhance the strength and stability of soil. Common geosynthetic materials include geogrids, geotextiles, and geomembranes. These materials are placed within the soil to increase its compressive strength and stability, thereby improving the performance of the retaining wall.

Reinforcement System: The reinforcement system is a structure used to connect the wall to the foundation, ensuring the overall stability and safety of the retaining wall. It typically consists of steel cables, reinforced concrete, or other materials, and is configured based on design requirements.

Drainage System: The drainage system is designed to remove water from the area behind the retaining wall, reducing water pressure on the wall. It typically consists of drainage ditches, drainage pipes, and other components, and is tailored to local hydrological conditions and climatic factors.

In the field of geotechnical engineering, retaining walls play a crucial role in stabilizing slopes, preventing erosion, and supporting various types of structures. Geosynthetic reinforcement retaining walls have emerged as a sustainable and innovative solution for enhancing the performance and durability of retaining walls.

Geosynthetic reinforcement retaining walls utilize a combination of geosynthetics and traditional materials to achieve greater stability and durability. Geosynthetics, such as geogrids and geotextiles, are used to reinforce the soil mass behind the wall, improving its compressive strength and stability. This results in a more robust and durable retaining wall that can withstand various loads and environmental conditions.

One of the key advantages of geosynthetic reinforcement retaining walls is their ability to reduce settlement and deformation. Traditional retaining walls are prone to settlement and deformation under heavy loads or over time, which can lead to structural failure and safety concerns. By using geosynthetics to reinforce the soil mass, geosynthetic reinforcement retaining walls can significantly reduce settlement and deformation, ensuring the longevity and stability of the wall.

Another advantage of geosynthetic reinforcement retaining walls is their ability to withstand high loads and seismic forces. The reinforced soil mass behind the wall provides a more stable foundation, capable of handling larger loads and resisting seismic shaking. This makes geosynthetic reinforcement retaining walls suitable for use in earthquake-prone areas or regions where heavy loads are common.

The design and construction of geosynthetic reinforcement retaining walls is based on sound engineering principles and takes into account various factors such as soil type, wall geometry, loading conditions, and environmental factors. The use of geosynthetics in combination with traditional materials allows for greater design flexibility, providing engineers with a range of options to customize the wall's performance and durability based on specific project requirements.

In conclusion, geosynthetic reinforcement retaining walls have emerged as a sustainable and innovative solution for enhancing the performance and durability of retaining walls in geotechnical engineering. By utilizing the unique properties of geosynthetics, these walls can achieve greater stability, load capacity, and durability compared to traditional retaining walls. As we continue to pursue sustainable infrastructure development, the use of geosynthetic reinforcement retaining walls will play a key role in ensuring the longevity and safety of critical infrastructure components.

Design

Designing a retaining wall reinforced with geosynthetic materials typically involves a comprehensive consideration of the project's soil conditions, the geometry of the wall, load requirements, and the characteristics of the chosen geosynthetic materials. Here are the basic steps for a design plan:

Site Investigation and Soil Analysis:

Conduct a detailed site investigation to gather information on soil properties, hydrological conditions, and topography.

Perform soil analysis to determine engineering properties, including shear strength, compression characteristics, etc.

Load Calculation:

Calculate and consider various loads acting on the retaining wall, including vertical loads, horizontal loads, groundwater loads, etc.

Account for potential seismic loads and perform calculations according to seismic design codes.

Wall Geometry:

Determine the geometry of the retaining wall, including slope, height, base width, and top width.

Select appropriate geosynthetic materials based on the backfill slope and the geometry of the retaining wall.

Geosynthetic Material Selection:

Choose suitable geosynthetic materials based on the load requirements and soil characteristics, such as geogrids, geotextiles, etc.

Consider the tensile strength, stiffness, puncture resistance, and other properties of the selected geosynthetic materials.

Stability Analysis:

Conduct stability analyses for the retaining wall, including sliding stability, overturning stability, bottom sliding stability, etc.

Consider the reinforcing effect of geosynthetic materials on the soil's tensile strength.

Drainage Design:

Design an effective drainage system to mitigate the adverse effects of water on the retaining wall.

Use drainage geosynthetics, such as drainage geogrids, to enhance drainage performance.

Detailed Design:

Design the details of the retaining wall, including the top structure, anti-seepage measures, etc.

Determine the arrangement of geosynthetic materials, including their depth and layers within the soil.

Construction Procedures and Quality Control:

Develop detailed construction plans to ensure the correct installation and fixation of geosynthetic materials.

Implement quality control during construction to inspect the quality of geosynthetic material placement and the robustness of connections.

These steps provide an overview of a comprehensive design plan. Actual retaining wall design should be based on the specific requirements and conditions of the project. It is recommended to involve professional civil or structural engineers to ensure the stability and safety of the retaining wall.

503.webp)

759.webp)

628.webp)