What is geotextile?

Geotextile: a geotextile is a synthetic, permeable fabric that is used with soil, rock, or any other geotechnical engineering material as an integral part of a man-made project, structure, or system. Geotextiles are designed to perform one or more functions such as separation, filtration, drainage, reinforcement, and protection. They are commonly used in civil and environmental engineering applications to improve the performance and longevity of infrastructure projects.

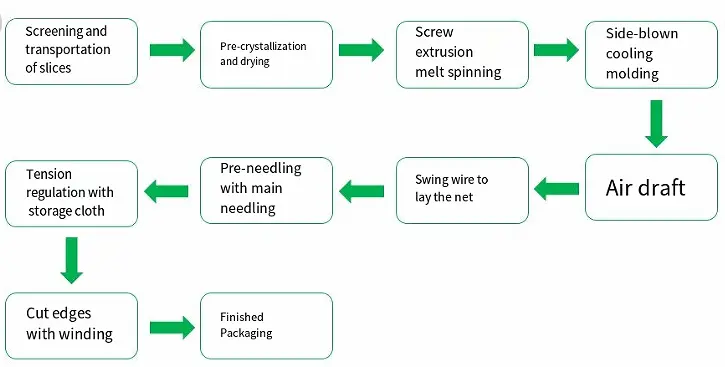

Geotextile production process

Specifications of geotextile

Geotextiles are typically made from synthetic fibers such as polypropylene (PP) and polyester (PET). | |

Types | Woven Geotextiles: These are made by weaving together two sets of yarns at right angles. They are strong and durable, making them suitable for applications requiring high tensile strength. Non-woven Geotextiles: These are produced through processes such as needle-punching or thermal bonding. Non-woven geotextiles are more flexible and are often used for filtration and separation. |

Thickness (mm) | Generally between 1 mm and 10 mm. |

Length (m) | Rolls can be up to 100 m in length. |

Weight | Ranges from lightweight (100g/m²) to heavyweight (800g/m²) |

Width | Common widths include 2 meters, 4 meters, and 6 meters. |

Color | Typically available in white or black, but other colors can be customized based on specific needs. |

Technical parameters

Tensile Strength (N/cm):

•Description: the maximum force the geotextile can withstand before breaking.

•Range: varies widely depending on the material and type, typically from 100 N/cm to 1000 N/cm.

8. Elongation at Break (%):

•Description: the percentage increase in length at which the geotextile breaks under tension.

•Range: usually between 10% and 100%.

9. Puncture Resistance (N):

•Description: the force required to puncture the geotextile with a standard probe.

•Range: can vary significantly, typically from 100 N to 1000 N.

10. Permeability (cm/s):

•Description: the rate at which water can pass through the geotextile.

•Range: generally between 0.01 cm/s and 10 cm/s.

11. UV Resistance:

•Description: the ability of the geotextile to resist degradation from ultraviolet light.

•Measurement: often expressed as a percentage of retained strength after exposure to UV light.

12. Chemical Resistance:

•Description: the ability of the geotextile to resist degradation from chemicals.

•Measurement: Tested against various chemicals and rated accordingly.

13. Water Absorption (%):

•Description: the amount of water absorbed by the geotextile.

•Range: typically between 0.1% and 5%.

14. Moisture Vapor Transmission Rate (MVTR) (g/m²/day):

•Description: the rate at which moisture vapor can pass through the geotextile.

•Range: varies depending on the material and type.

15. Friction Angle (°):

•Description: the angle at which the geotextile can maintain frictional contact with soil or other materials.

•Range: usually between 20° and 40°.

16. Stiffness (N/cm):

•Description: the resistance of the geotextile to bending.

•Range: varies depending on the material and type.

Prices of geotextile

1. Material Type:

•Woven Geotextiles: typically made from polyester or polypropylene fibers. Prices can range from $0.50 to $2.00 per square meter.

•Non-Woven Geotextiles: made from short fibers or filaments bonded together. Prices can range from $1.00 to $3.00 per square meter.

•Composite Geotextiles: combine woven and non-woven layers. Prices can range from $2.00 to $5.00 per square meter.

2. Size and Thickness:

•Small Rolls: smaller rolls (e.g., 50 m²) may have a higher price per square meter due to lower production efficiency.

•Large Rolls: larger rolls (e.g., 200 m²) often offer a lower price per square meter due to economies of scale.

•Thickness: thicker geotextiles generally cost more than thinner ones due to the increased amount of material used.

3. Quality and Standards:

•High-Quality Materials: products that meet high industry standards (e.g., ASTM, ISO) can be more expensive.

•Certifications: geotextiles with additional certifications (e.g., environmental, safety) may come at a premium.

4. Application and Usage:

•General Use: standard geotextiles for basic applications are typically less expensive.

•Specialized Use: geotextiles designed for specific applications (e.g., erosion control, landfill lining) can be more costly due to specialized properties.

5. Market Factors:

•Supply and Demand: market conditions, such as supply chain disruptions or high demand, can affect prices.

•Supplier and Location: prices can vary between different suppliers and regions. Local suppliers may offer competitive pricing and better service.

6. Additional Costs:

•Installation: some suppliers may offer installation services, which can add to the overall cost.

•Transportation: shipping costs can vary based on distance and logistics.

For the most accurate and up-to-date pricing information, it is recommended to contact multiple suppliers and request detailed quotes based on your specific requirements.

Advantages of Geotextile

1. Separation:

•Description: geotextiles prevent the mixing of different soil layers, maintaining their individual properties.

•Benefit: ensures that fine particles do not migrate into coarser materials, preserving the integrity of the soil structure.

2. Filtration:

•Description: geotextiles allow water to pass through while retaining soil particles.

•Benefit: prevents soil erosion and maintains the stability of the soil layer.

3. Drainage:

•Description: geotextiles facilitate the movement of water, acting as a drainage layer.

•Benefit: reduces hydrostatic pressure and prevents waterlogging, improving overall soil stability.

4. Reinforcement:

•Description: geotextiles add tensile strength to weak soils, enhancing their load-bearing capacity.

•Benefit: improves the structural integrity of roadways, embankments, and other infrastructure.

5. Protection:

•Description: geotextiles protect underlying layers from mechanical damage.

•Benefit: extends the lifespan of infrastructure by preventing damage from external forces.

6. Cost-Effective:

•Description: geotextiles are generally less expensive than traditional construction materials.

•Benefit: Provides a cost-effective solution for various civil engineering applications.

7. Ease of Installation:

•Description: geotextiles are lightweight and flexible, making them easy to handle and install.

•Benefit: reduces labor costs and installation time.

8. Environmental Benefits:

•Description: geotextiles are often made from recyclable materials and can be reused.

•Benefit: minimizes environmental impact and promotes sustainable construction practices.

Applications of Geotextile

1. Reinforcement:

•Description: geotextiles can be used to reinforce soil and improve its load-bearing capacity. This is particularly useful in areas with weak or unstable soil conditions.

•Applications: road and railway subgrades, retaining walls, embankments and slope stabilization

2. Filtration:

•Description: geotextiles act as a filter to allow water to pass through while retaining soil particles. This prevents the clogging of drainage systems and maintains the integrity of the soil structure.

•Applications: drainage systems, landfill liners, erosion control, pond and reservoir linings.

3. Separation:

•Description: geotextiles can separate different layers of soil or materials to prevent mixing and maintain distinct layers. This is important in maintaining the structural integrity of various constructions.

•Applications: road bases, railway ballast,landscaping, foundation works

4. Drainage:

•Description: geotextiles facilitate the movement of water through the soil, helping to reduce excess water pressure and prevent waterlogging. This improves the stability and performance of the construction.

•Applications: subsurface drainage systems, french drains, sports fields and green roofs

5. Erosion Control:

•Description: geotextiles can protect soil from erosion caused by wind, water, or other forces. They help to stabilize soil and promote vegetation growth, which further enhances erosion resistance.

•Applications: stream banks, slopes, construction sites, and coastal areas.

6. Lining and Barrier Systems:

•Description: geotextiles can be used as liners or barriers to contain or exclude fluids or gases. This is particularly important in environmental applications to prevent contamination.

•Applications: Landfills, waste containment, Oil and gas storage, water reservoirs.

7. Pavement Subbase Stabilization:

•Description: geotextiles can be placed between the subgrade and the pavement to improve the overall performance and longevity of the pavement. They help distribute loads and reduce the risk of cracking and rutting.

•Applications: highway pavements, airport runways, and parking lots.

8. Vegetation Matting:

•Description: geotextiles can be used as a base for vegetation matting, providing a stable and permeable surface for plant roots to grow. This is useful in green infrastructure and ecological restoration projects.

•Applications: green roofs, ecosystem restoration, landscape design.

9. Seawalls and Coastal Protection:

Description: geotextiles can be used in coastal protection structures to prevent erosion and provide stability. They are often used in conjunction with other materials like rock and concrete.

•Applications: seawalls, breakwaters, and coastal revetments

10. Turf Reinforcement:

•Description: geotextiles can reinforce turf to improve its durability and resistance to wear. This is particularly useful in high-traffic areas.

•Applications: athletic fields, golf courses and parks and recreational areas

Each application leverages the unique properties of geotextiles, such as their strength, filtration, and drainage capabilities, to address specific engineering and environmental challenges.

Conclusion

Geotextiles are versatile materials with a wide range of applications in civil and environmental engineering. Understanding their technical paramters, prices, and applications can help you make informed decisions when selecting the right geotextile for your project.

897.webp)

942.webp)

237.webp)