High-Density Polyethylene (HDPE) geomembranes are increasingly used worldwide as an effective solution for environmental and civil engineering projects. Malaysia, as a developing country with a strong focus on infrastructure and environmental protection, has seen significant applications of HDPE geomembranes in recent years. This article explores the various uses, benefits, and future prospects of HDPE geomembranes in Malaysia.

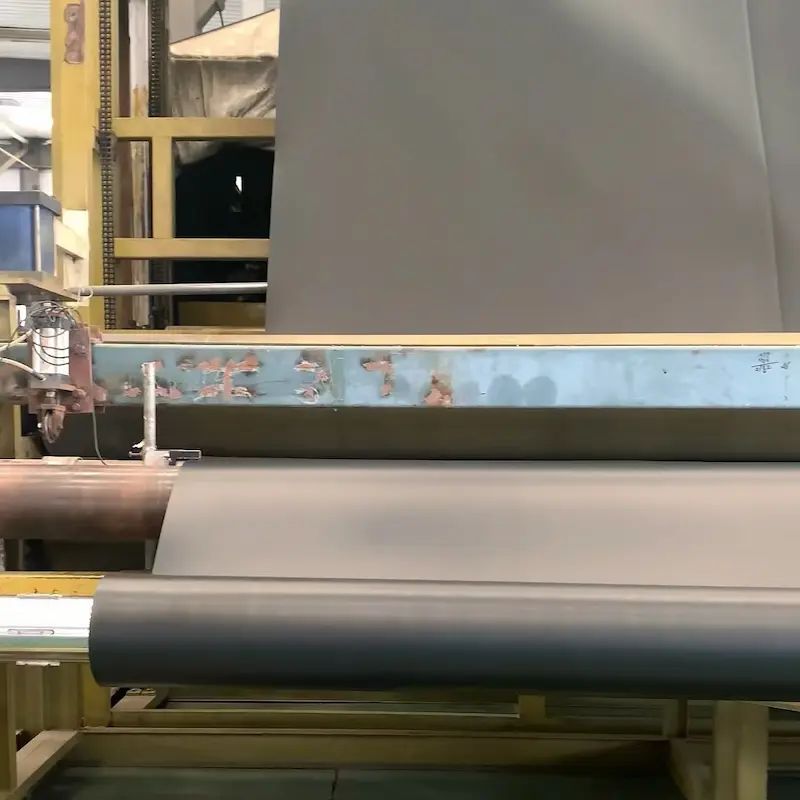

Characteristics of HDPE Geomembrane

HDPE geomembranes are impermeable liners made from polyethylene resin. Their key features include:

High Chemical Resistance: Resistant to a wide range of chemicals, making them ideal for hazardous waste containment.

Durability: Long service life due to resistance to UV radiation, punctures, and environmental stress cracking.

Flexibility: Adaptable to uneven terrains and capable of withstanding various weather conditions.

Eco-friendliness: Manufactured from virgin raw materials, they are recyclable and have a minimal environmental footprint.

553064.webp)

Applications in Malaysia

1. Landfill Liners and Covers

One of the most common uses of HDPE geomembranes in Malaysia is in landfills. These geomembranes act as barriers to prevent leachate from contaminating the groundwater. They are also used as capping systems to reduce gas emissions and manage rainwater infiltration. Given Malaysia's focus on sustainable waste management, the use of HDPE geomembranes aligns with the country’s environmental goals.

2. Water Reservoirs and Aquaculture

In regions with limited water resources, HDPE geomembranes are used to line water reservoirs, ensuring water conservation by minimizing seepage. In the aquaculture industry, which is thriving in Malaysia, geomembranes provide a clean and safe environment for fish and shrimp farming. Their chemical resistance ensures that water quality is maintained, reducing the risk of disease.

3. Mining Industry

Malaysia’s mining sector benefits from HDPE geomembranes in heap leach pads, tailing ponds, and wastewater containment. The impermeability of these geomembranes ensures that toxic substances from mining activities do not seep into the surrounding environment, thus protecting ecosystems.

4. Infrastructure Projects

HDPE geomembranes are used in road and railway construction projects to prevent water infiltration and enhance the stability of subgrades. Additionally, they are employed in tunnel linings to control seepage and improve durability.

5. Oil and Gas Sector

In the oil and gas industry, HDPE geomembranes are utilized in secondary containment systems, evaporation ponds, and spill containment areas. Their high chemical resistance makes them suitable for managing hazardous materials in this sector.

Advantages of HDPE Geomembrane

Cost-effectiveness

HDPE geomembranes are a cost-effective solution compared to traditional materials. Their durability and low maintenance requirements reduce long-term operational costs.

Environmental Protection

By providing a barrier against contaminants, these geomembranes play a critical role in protecting soil and water resources. This is especially important in Malaysia, where environmental preservation is a growing concern.

Versatility

The adaptability of HDPE geomembranes to different applications makes them a preferred choice across various industries. Their ease of installation further enhances their appeal.

Challenges and Solutions

Installation Challenges

Improper installation can compromise the effectiveness of HDPE geomembranes. To address this, Malaysia has developed stringent installation standards and guidelines. Additionally, employing skilled technicians and using high-quality materials from reliable manufacturers can mitigate these risks.

Climatic Conditions

Malaysia’s tropical climate, characterized by high temperatures and humidity, can impact the performance of geomembranes. UV-resistant HDPE geomembranes and proper anchoring techniques are essential to ensure long-term performance.

Future Prospects

The demand for HDPE geomembranes in Malaysia is expected to grow due to:

Increased Infrastructure Development: Ongoing projects under the 12th Malaysia Plan (2021-2025) highlight the need for advanced construction materials.

Stronger Environmental Regulations: Enhanced regulations for waste management and water resource protection will drive the adoption of HDPE geomembranes.

Growth in Aquaculture and Agriculture: As these sectors expand, the need for efficient water management systems will rise, boosting the demand for geomembranes.

Item

Unit

Index

1

Thickness

mm

0.30

0.50

0.75

1.00

1.25

1.50

2.00

2.50

3.00

2

Density

g/cm3

≧0.940

3

Tensile yield strength

N/mm

≧4

≧7

≧10

≧13

≧16

≧20

≧26

≧33

≧40

4

Tensile breaking strength

N/mm

≧6

≧10

≧15

≧20

≧25

≧30

≧40

≧50

≧60

5

Yield elongation

%

-

-

-

≧11

6

Break Elongation

%

≧600

7

Right-angle

Tearing strength

N

≧34

≧56

≧84

≧115

≧140

≧170

≧225

≧280

≧340

8

Puncture

strength

N

≧72

≧120

≧180

≧240

≧300

≧360

≧480

≧600

≧720

9

Carbon black content

%

2.0~3.0

10

Dispersion

of carbon black

-

There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist.

11

Oxidation induction time

min

≧60

12

Low temperature impact embrittlement properties

-

Pass

13

Water vapor permeability coefficient

g.cm/

(cm2.s.Pa)

≦1.0*10-13

14

Dimensional stability

%

±2.0

Note

Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation.

HDPE geomembranes have proven to be a versatile and indispensable material for various applications in Malaysia. Their role in environmental protection, resource conservation, and infrastructure development underscores their significance. With advancements in manufacturing technologies and increasing awareness of their benefits, HDPE geomembranes are poised to play an even more critical role in Malaysia’s sustainable development journey.

If you are interested in our products, please contact Tracy:

Tel&WhatsApp:+86 17853574041

Email:sale@hygeosynthetics.com

606.webp)

244.webp)

503.webp)

759.webp)

897.webp)

942.webp)

237.webp)