Enhancing Alumina Red Mud Storage Facilities with HDPE Geomembranes and Filament Nonwoven Geofabrics

Alumina production generates a byproduct known as red mud, a highly alkaline residue requiring secure storage to prevent environmental contamination. The integration of High-Density Polyethylene (HDPE) geomembranes with filament nonwoven geofabrics has emerged as an effective solution for enhancing the safety and efficiency of red mud storage facilities.

Typical Properties of HDPE Geomembranes

| Property | Value Range |

|---|---|

| Thickness | 0.2mm - 3.0mm |

| Lifespan | Up to 50 years |

| Puncture Strength | High |

| UV Resistance | Excellent |

| Chemical Resistance | Excellent |

Understanding Red Mud and Its Storage Challenges

Red mud is a caustic byproduct of the Bayer process used in alumina extraction. Its high pH levels and fine particle size pose significant environmental risks, including soil and water contamination. Consequently, designing storage facilities that effectively contain red mud is crucial.

Role of HDPE Geomembranes in Red Mud Containment

HDPE geomembranes are synthetic liners renowned for their low permeability and chemical resistance, making them ideal for containing hazardous materials like red mud. Their durability and resistance to ultraviolet (UV) radiation further enhance their suitability for long-term applications.

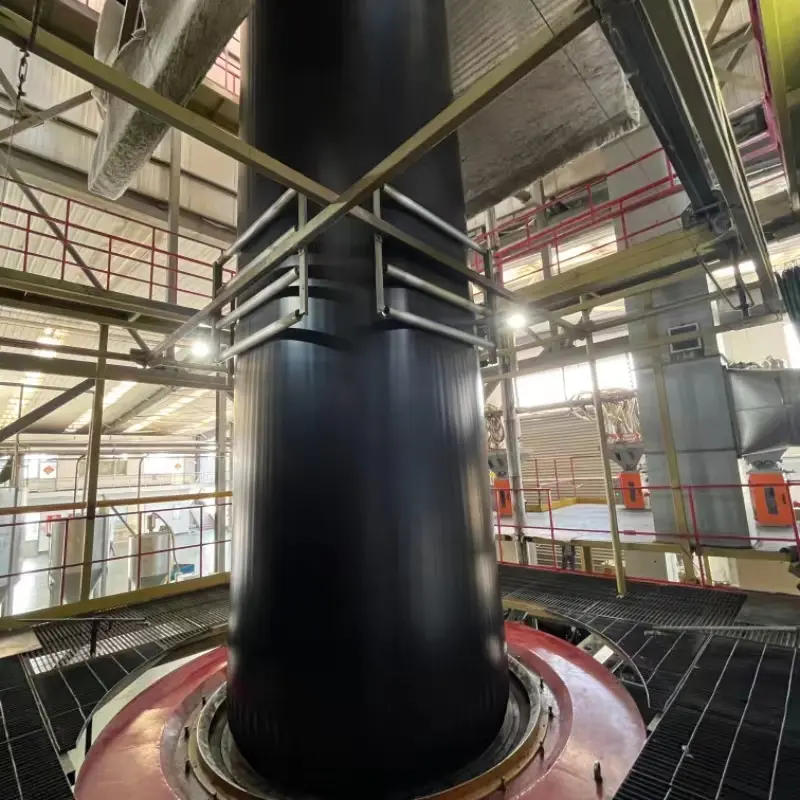

Alumina Red Mud Storage Facility Project in Indonesia

Project background:

Red mud is a mixture of waste residues and wastewater generated in the process of alumina production. It is called red mud because it is rich in iron oxide (ferrous oxide oxidizes to ferric oxide in open conditions), giving it a red color. Red mud is highly alkaline and contains aluminum ions as well as harmful substances such as fluorine and chromium. If not properly treated, it can cause environmental pollution to water and soil. Therefore, effective anti-seepage measures are essential for red mud storage facilities. Typically, dams are constructed at valley mouths or on flat terrain to intercept and contain red mud, creating storage capacity for its proper management.

The HDPE smooth geomembrane produced by our company has been selected for the Alumina Red Mud Storage Facility Project in Indonesia due to its stable quality and performance exceeding national standards. It has gained high recognition from customers in practical use.

Problems To Be Solved

1, Seepage Prevention Issue:

Alumina red mud contains harmful substances, and if it permeates into the soil or groundwater, it can lead to severe environmental problems.

2, Soil Stability Issue:

The soil in red mud storage facilities is prone to erosion, instability, and the risk of soil displacement and landslides.

3, Structural Durability Issue:

The structure of red mud storage facilities is susceptible to environmental impacts, limiting its lifespan.

4, Engineering Cost Issue

Traditional maintenance and repair costs for engineering structures can be high, impacting long-term economic efficiency.

Our Solutiions

1,Seepage Prevention Issue:

Solution: Using HDPE geomembrane as an impermeable barrier effectively prevents the infiltration of harmful substances from red mud, reducing the risk of environmental pollution.

2, Soil Stability Issue:

Solution: Employing filament nonwoven geofabric reinforces the soil, enhances stability, slows down the erosion process, and prevents soil displacement and landslides.

3, Structural Durability Issue:

Solution: The combined use of HDPE geomembrane and filament nonwoven geofabric improves overall structural durability, reducing the likelihood of structural damage and extending the lifespan of the red mud storage facility.

4, Engineering Cost Issue:

Solution: By utilizing HDPE geomembrane and filament nonwoven geofabric, maintenance and repair costs can be reduced, enhancing the economic efficiency of the project and more effectively utilizing project funds.

Funtions of Products in Every Layer

1, HDPE Geomembrane:

Possesses corrosion resistance and anti-aging properties, effectively serving as a barrier against seepage and isolation.

2, Upper Layer Filament Spunbond Needle-punched Geofabric:

Provides permeability and anti-filtering functions while preventing the frictional force generated by sharp objects or uneven loads from damaging the membrane.

3, Lower Layer Filament Spunbond Needle-punched Geofabric:

Acts as a protective layer for the geomembrane, preventing damage from sharp objects in the underlying soil, especially under long-term loading conditions.

643086.webp)

Specific Products We Use

1, 2mm HDPE geomembrane

A 2mm HDPE geomembrane is a geosynthetic liner made of high-density polyethylene (HDPE) material with a thickness of 2 millimeters. HDPE geomembranes are commonly used for waterproofing and seepage control in various engineering projects, including landfill sites, wastewater treatment plants, reservoirs, mining operations, and chemical facilities. In the Alumina Red Mud Storage Facility Project, the 2mm HDPE geomembrane plays a crucial role, offering the following key functions and advantages:

1, Seepage Prevention: The 2mm thick HDPE geomembrane serves as a reliable barrier, effectively preventing the penetration of harmful substances from alumina red mud into the surrounding soil and groundwater.

2, Isolation: The geomembrane isolates the red mud from the surrounding environment, preventing the diffusion of chemicals that could negatively impact the soil and water.

3, Stability: The 2mm thickness of the HDPE geomembrane provides sufficient physical strength and stability to withstand the pressure and loads within the structure of the red mud storage facility.

4, Corrosion Resistance: HDPE geomembranes exhibit excellent corrosion resistance, maintaining stability over the long term in environments containing chemical substances.

5, Durability: Due to its robustness and long lifespan, the 2mm HDPE geomembrane ensures the sustainability and long-term benefits of the Alumina Red Mud Storage Facility Project.

2,600g/m² filament spunbond needle-punched geofabric

600g/m² filament spunbond needle-punched geofabric is a geotextile fabric with a weight of 600 grams per square meter. It uses filament spunbond technology and is further reinforced through needle-punching. This type of geofabric is commonly used in engineering projects, and its primary functions in this project include:

1, Soil Reinforcement and Enhancement:

The filament spunbond needle-punched geofabric, with its reinforced fibers through needle-punching, effectively strengthens the soil, improving tensile strength and stability.

2, Prevention of Soil Erosion:

The geofabric covering helps slow down water flow, reducing soil erosion and preventing soil loss.

3, Filtration and Drainage:

Designed to allow water to pass through while blocking the passage of particles, the geofabric acts as a filter and facilitates drainage.

Why Choose Us

1, Haoyang Invironmental is a Chinese manufacturing company established in 2008.

From the outset the objective was to manufature high-performance geosythetic products to the highest quality standard. The company's ethos is to exceed the expections of our customers with high quality products and spport services.Now, let me show you our factories:

|  |  |

|  | 841186.webp) |

2, Quality in Manufacturing

We Achieved ISO 9001 certification. This certification is internationally recognized for quality management systems, serving as a testament to a company's commitment to quality and the effectiveness of its quality management system.

Haoyang Invironmental is China's leading manufacturer of geotextiles. Since its formation in 2008, millions of geotextile products have been deployed along landfills, water projects and watercourses, railway projects, etc. Their use is due to the quality of the products, their cost effectiveness and the comprehensive help provided to design engineers and contractors at every stage of a project.

Our products have been designed and are manufactured to meet the most demanding performance levels. Using a modern computer-controlled plant, all products are manufactured in an ISO9001 environment and sampled and tested to the appropriate standards.

528151.webp)

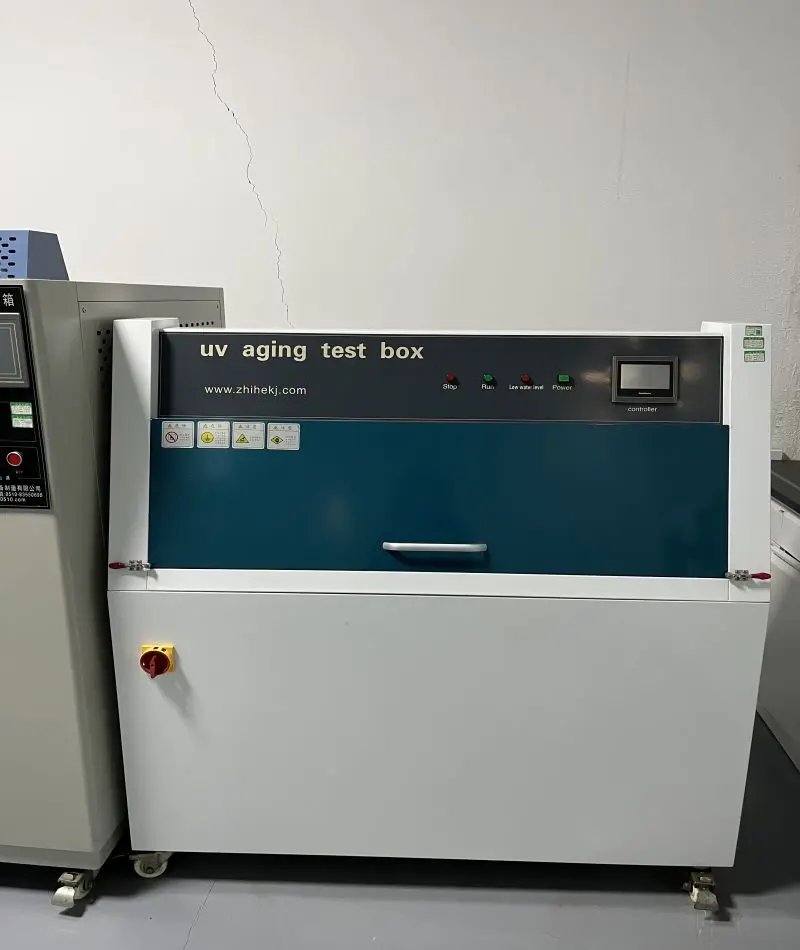

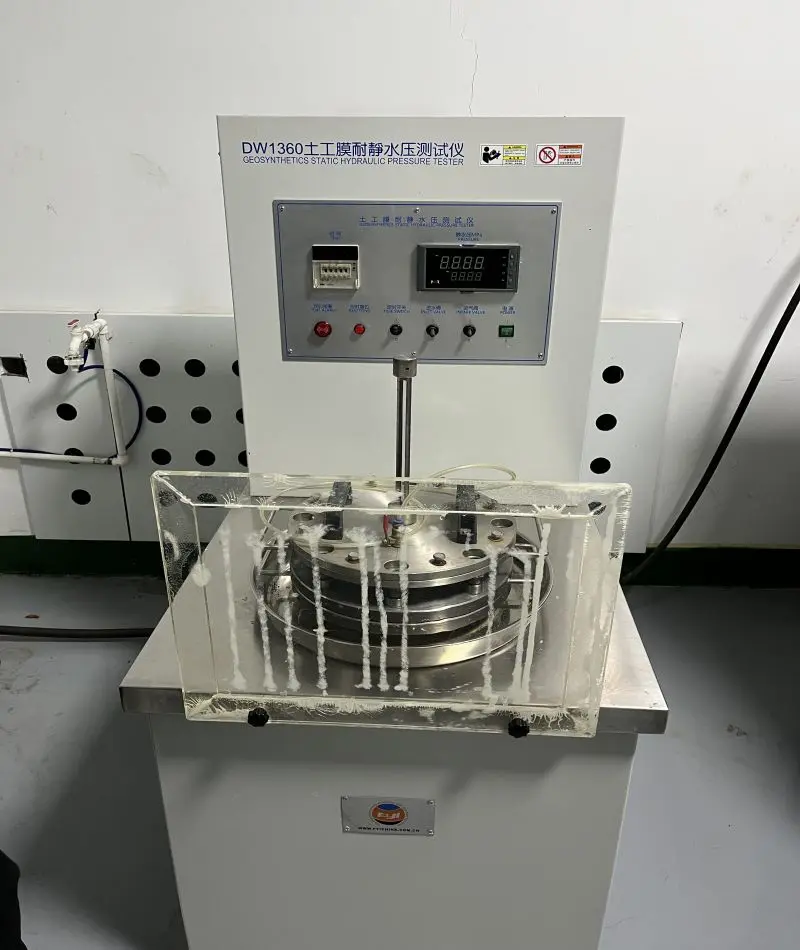

3, Strict Quality Inspection System

Our company consistently upholds rigorous quality inspection as a core commitment. Our quality inspection process spans every step from raw material procurement to manufacturing, ensuring that our products meet the highest standards and customer expectations. We strictly implement advanced quality control measures, including comprehensive inspections, rigorous testing, and thorough audits. Our dedicated quality inspection team consists of experienced professionals who remain vigilant, dedicated to identifying and correcting any potential quality issues. By introducing advanced technologies and processes, we ensure that each product undergoes meticulous scrutiny to guarantee its highest levels of performance, reliability, and durability. Our commitment is to deliver excellent products to customers, and we firmly believe that through adhering to strict quality inspection, we can consistently provide high-quality solutions for our customers.

|  |  |

| 298350.webp) |

FAQ

Q1: What is the role of HDPE geomembrane in the alumina red mud storage facility?

HDPE geomembrane serves as a impermeable liner, preventing the leakage of red mud and protecting the surrounding environment from potential contamination.

Q2: How does filament nonwoven geofabric complement HDPE geomembrane in the storage facility?

Filament nonwoven geofabric acts as a reinforcing and protective layer, enhancing the stability of the geomembrane, preventing punctures, and providing additional strength.

Q3: What challenges does this combination address in red mud storage?

The combination of HDPE geomembrane and filament nonwoven geofabric addresses challenges such as soil stability, erosion prevention, and long-term protection against the caustic nature of red mud.

Q4: Is this solution environmentally friendly?

Yes, the use of HDPE geomembrane and filament nonwoven geofabric provides an environmentally friendly solution by containing and isolating the red mud, preventing its interaction with the surrounding ecosystem.

Q5: How does this combination contribute to the longevity of the storage facility?

HDPE geomembrane, along with filament nonwoven geofabric, creates a durable and resistant barrier, ensuring the longevity of the storage facility by minimizing the risk of leaks, erosion, and structural degradation over time.

897.webp)

942.webp)

237.webp)