HDPE geomembrane specifications: detailed introduction

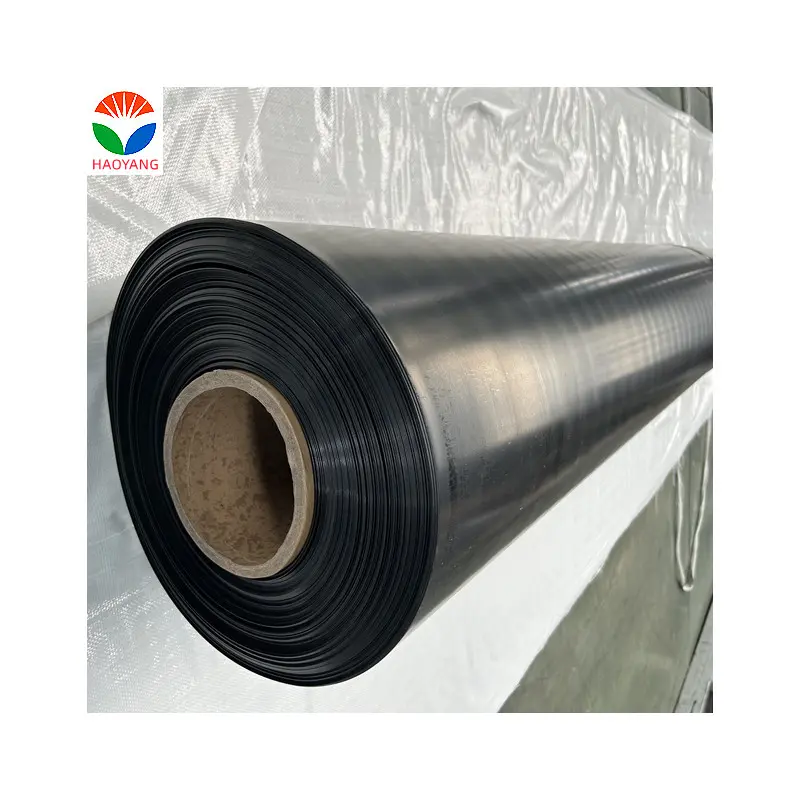

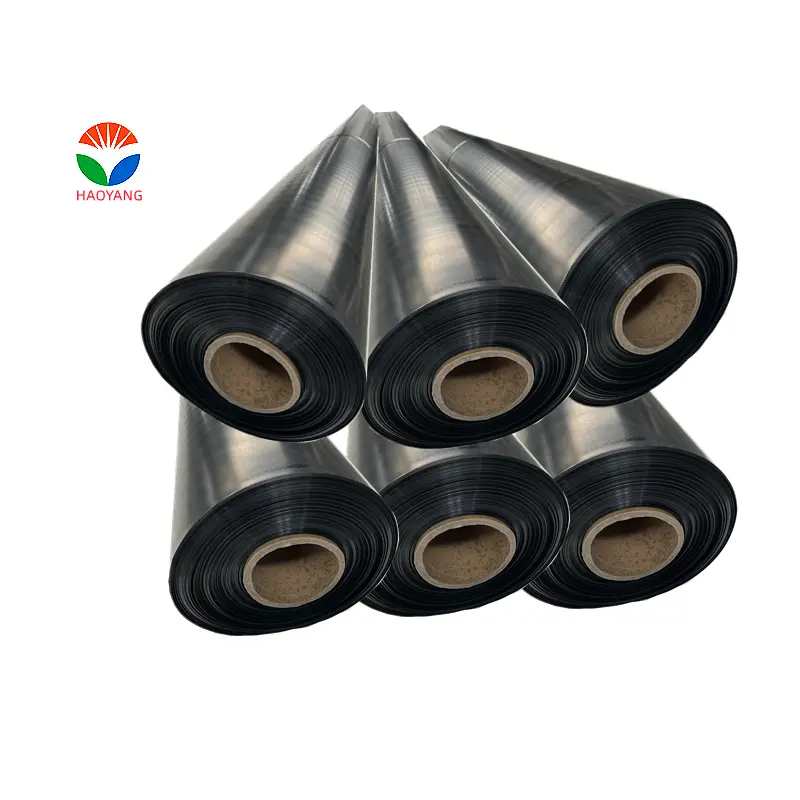

HDPE geomembrane, full name high-density polyethylene mulch, is a commonly used geosynthetic material with excellent anti-penetration performance and durability. It is widely used in water conservancy projects, environmental projects, transportation projects and other fields.

The following is a detailed introduction to the specifications of HDPE geomembrane:

1. Specification classification

The specifications of HDPE geomembrane usually include the following aspects:

Thickness: The thickness of HDPE geomembrane is usually measured in millimeters (mm). Common thicknesses are 0.5mm, 0.75mm, 1.0mm, etc.

Width: The width of HDPE geomembrane is usually measured in meters (m). Common widths are 2m, 4m, 6m, etc.

Length: The length of HDPE geomembrane is usually measured in meters (m) and can be customized according to project needs. Common lengths are 50m, 100m, 200m, etc.

2. Technical indicators

The technical indicators of HDPE geomembrane mainly include the following aspects:

Tensile Strength: The tensile strength of HDPE geomembrane refers to the maximum tensile force it can withstand during the stretching process, usually expressed in megapascals (MPa).

Elongation at Break: The elongation at break of HDPE geomembrane refers to the elongation in the length direction when tensile failure occurs, usually expressed as a percentage (%).

Tear Resistance: The tear strength of HDPE geomembrane refers to its resistance when subjected to tearing force, usually expressed in Newton (N).

Puncture Resistance: The puncture resistance of HDPE geomembrane refers to its ability to resist puncture by external sharp objects, usually expressed in Newton (N).

3. Application scope

The specifications of HDPE geomembrane are suitable for various engineering application scenarios:

Water conservancy projects: Used as anti-seepage layers in water conservancy projects such as reservoirs, canals, and rivers.

Environmental Engineering: Used as anti-penetration layer in environmental projects such as landfills and sewage treatment plants.

Traffic Engineering: Used as waterproof and anti-penetration layer in traffic projects such as highways and railways to protect the basic soil.

4. Advantages and Development Trends

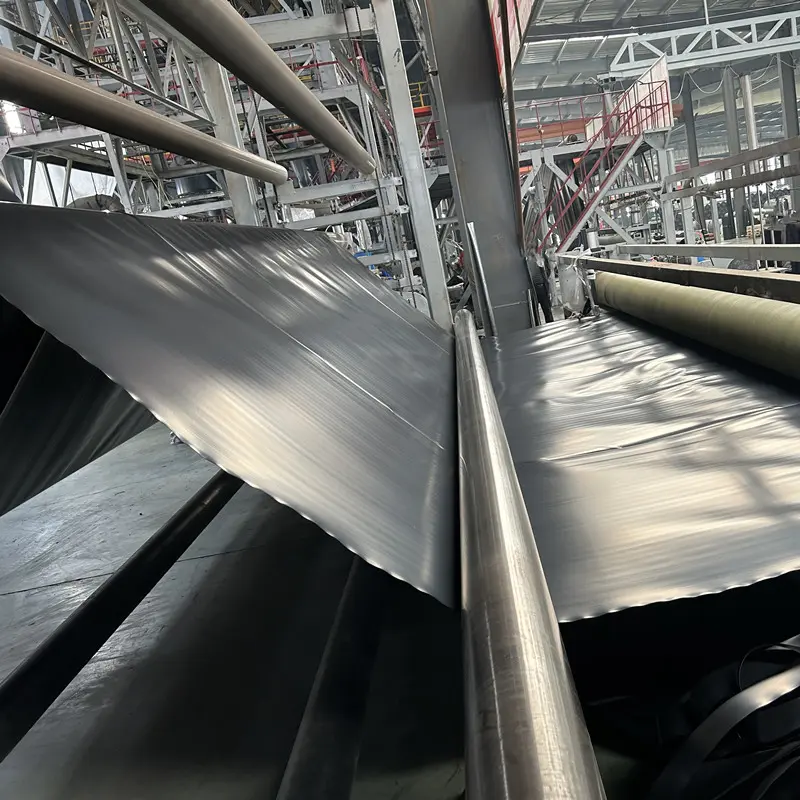

HDPE geomembrane has the advantages of good anti-penetration performance, strong durability, and convenient construction, and has gradually become one of the mainstream products among geosynthetic materials. In the future, with the continuous advancement of technology and the increase in market demand, the specifications of ordinary HDPE geomembranes will become more and more diversified, and their application scope will be further expanded to provide more reliable anti-penetration protection for various projects.

Conclusion

The above is a detailed introduction to the specifications of HDPE geomembrane. I hope it can provide you with some reference and help. As a high-quality geosynthetic material, HDPE geomembrane has broad application prospects and important social significance, and will play an important role in various projects.

Schedule:

The following represents the national standard specification parameters of ordinary HDPE geomembrane for reference.

Common HDPE geomembrane (GH-1 type) technical performance index GBT17643-2011

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

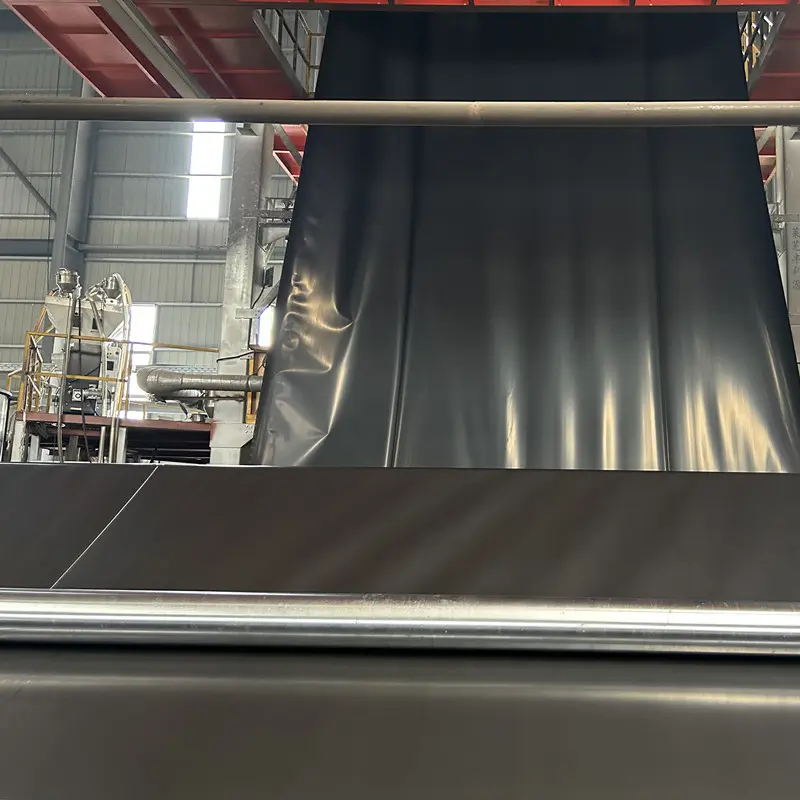

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

We manufacture HDPE geomembranes for customers worldwide, offering a comprehensive range of specifications. Our products are known for their high quality, competitive pricing, and versatility. Whether for landfill liners, pond liners, or containment barriers, we welcome you to choose our geomembranes for your project needs.

![]() 0.75 Double-sided smooth HDPE geomembrane.pdf

0.75 Double-sided smooth HDPE geomembrane.pdf

![]() 1 Double-sided smooth HDPE geomembrane.pdf

1 Double-sided smooth HDPE geomembrane.pdf

897.webp)

942.webp)

237.webp)