What is HDPE Geomembrane?

HDPE geomembrane is a synthetic liner or barrier made from high-density polyethylene polymer. It is widely used to prevent fluid migration in construction and environmental projects. Known for its robust performance, HDPE geomembranes provide excellent resistance to punctures, UV rays, chemicals, and extreme temperatures.

Key Features of HDPE Geomembranes

ØChemical Resistance: Provides excellent resistance to a wide range of chemicals, including acids, alkalis, and hydrocarbons, making it suitable for industrial and environmental projects.

ØUV Protection: Designed to withstand prolonged exposure to ultraviolet radiation, ensuring long-lasting performance in outdoor applications.

ØLow Permeability: Acts as an effective barrier to fluids and gases, preventing leakage and seepage in containment systems.

ØDurability and Longevity: Has a lifespan of over 30 years when properly installed and maintained, making it a cost-effective choice for long-term projects.

ØFlexibility: Adapts easily to different terrain types, ensuring a secure fit in uneven or irregular surfaces.

ØTemperature Resistance: Performs reliably in extreme temperatures ranging from -40°C to 60°C, suitable for diverse environmental conditions.

ØEnvironmentally Friendly: Non-toxic and safe for use in water conservation and aquaculture projects.

Applications of HDPE Geomembranes in Kenya

1. Water Reservoirs and Irrigation: HDPE geomembranes are used to line water reservoirs, canals, and ponds, preventing seepage and water loss.

2. Landfills and Waste Management: They provide a reliable lining system for hazardous and non-hazardous waste containment.

3. Mining: Used as liners in heap leaching ponds and tailings dams to prevent leakage of toxic substances.

4. Aquaculture: Fish farming ponds benefit from HDPE linings to maintain water quality and reduce operational costs.

5. Road and Infrastructure Projects: Prevent erosion and control groundwater movement beneath roads and railways.

6. Mining: Used as liners in heap leaching ponds and tailings dams to prevent leakage of toxic substances.

7. Aquaculture: Fish farming ponds benefit from HDPE linings to maintain water quality and reduce operational costs.

8. Road and Infrastructure Projects: Prevent erosion and control groundwater movement beneath roads and railways.

Market Demand for HDPE Geomembranes in Kenya

The increasing focus on sustainable development and the growth of construction, agriculture, and mining industries drive the demand for HDPE geomembranes in Kenya.

Table 1: Market Segmentation by Application (2025 Projection)

Application | Market Share (%) |

Water Reservoirs | 35% |

Waste Management | 25% |

Mining and Industrial | 20% |

Aquaculture | 10% |

Infrastructure Projects | 10% |

Benefits of Using HDPE Geomembrane

1. Cost-Effective Solution

Though the initial investment might be higher, the durability and low maintenance costs make HDPE geomembranes economically viable in the long run.

2. Environmental Protection

By providing a reliable barrier, HDPE liners prevent contamination of soil and groundwater, aligning with Kenya’s environmental regulations.

3. Versatile Installation Options

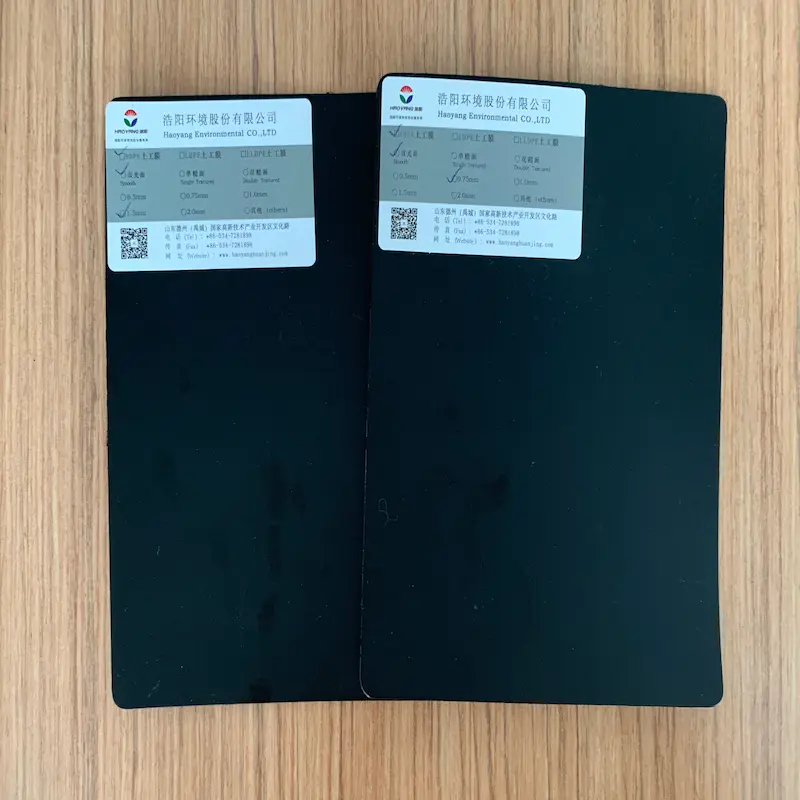

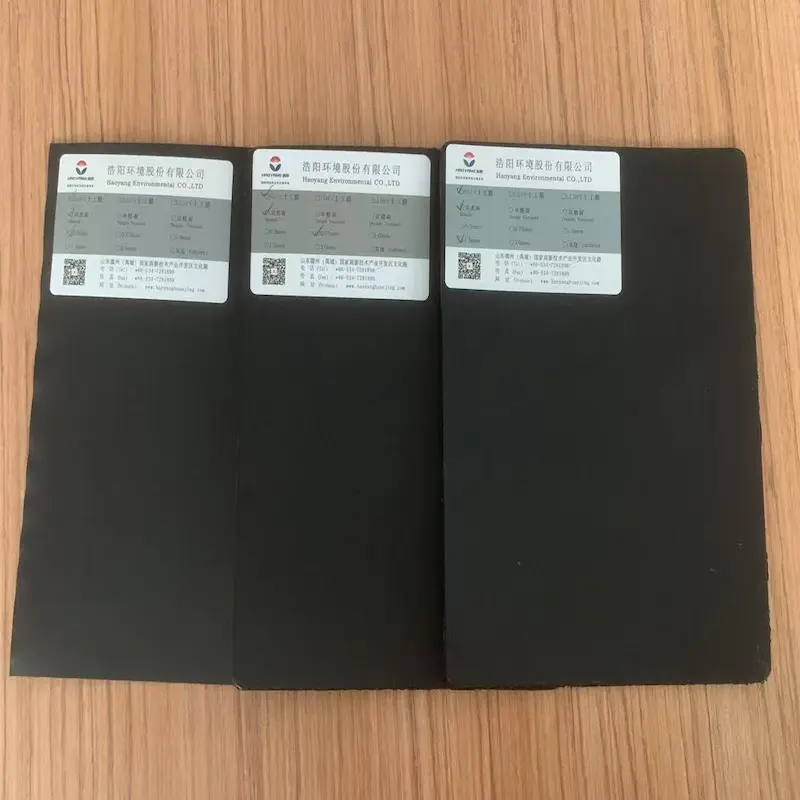

Available in a range of thicknesses (0.5mm to 3mm), HDPE geomembranes can be tailored to project-specific needs.

Case Study: HDPE Geomembrane in Kenyan Water Conservation Project

In 2023, a major irrigation project in Machakos County adopted HDPE geomembrane to line a 50,000 cubic meter reservoir. The result was a 40% reduction in water loss and significant improvements in agricultural productivity. The initial cost of lining was recouped within two growing seasons due to enhanced water retention.

Selection Criteria for HDPE Geomembranes

When choosing an HDPE geomembrane, consider the following:

1. Thickness: Standard thickness ranges from 0.5mm to 3mm, depending on application.

2. UV Resistance: Ensure the material is UV-stabilized for outdoor use.

3. Seam Strength: High-quality seams prevent leakage and ensure long-term performance.

Table 2: Recommended HDPE Geomembrane Thickness by Application

Application | Recommended Thickness (mm) |

Water Reservoirs | 1.0 - 1.5 |

Landfills | 2.0 - 2.5 |

Aquaculture | 0.75 - 1.0 |

Mining | 1.5 - 2.5 |

Infrastructure Projects | 1.0 - 2.0 |

Installation and Maintenance

Proper installation is crucial to maximize the performance of HDPE geomembranes. Key steps include:

Ø Surface Preparation: Ensure a smooth, debris-free surface.

Ø Seaming: Use fusion welding for secure joints.

Ø Anchoring: Properly secure edges to prevent movement.

Maintenance involves regular inspection for punctures, UV degradation, and seam integrity. Repairs should be conducted immediately to prevent further damage.

Pricing of HDPE Geomembranes in Kenya

The cost of HDPE geomembranes in Kenya varies depending on factors such as thickness, quality, and supplier. Typical prices per square meter are outlined below:

Table 3: Price Range of HDPE Geomembrane in Kenya (2025 Estimate)

Thickness (mm) | Price Range (KES per square meter) |

0.5 | 250 - 350 |

1.0 | 400 - 600 |

1.5 | 400 - 600 |

2.0 | 800 - 1,000 |

2.5 | 1,000 - 1,200 |

Prices fluctuate based on market demand, import costs, and installation complexity. It is advisable to source from reputable suppliers to ensure quality and performance.

Conclusion

HDPE geomembranes offer a durable, cost-effective, and environmentally friendly solution for a wide range of applications in Kenya. The growing market, driven by infrastructure and environmental conservation initiatives, makes them an essential material in modern construction and resource management. Selecting the right thickness and ensuring proper installation will ensure long-term benefits and sustainability.

Whether it’s water conservation, waste containment, or industrial usage, HDPE geomembranes are the backbone of reliable engineering solutions in Kenya’s development landscape.

897.webp)

942.webp)

237.webp)