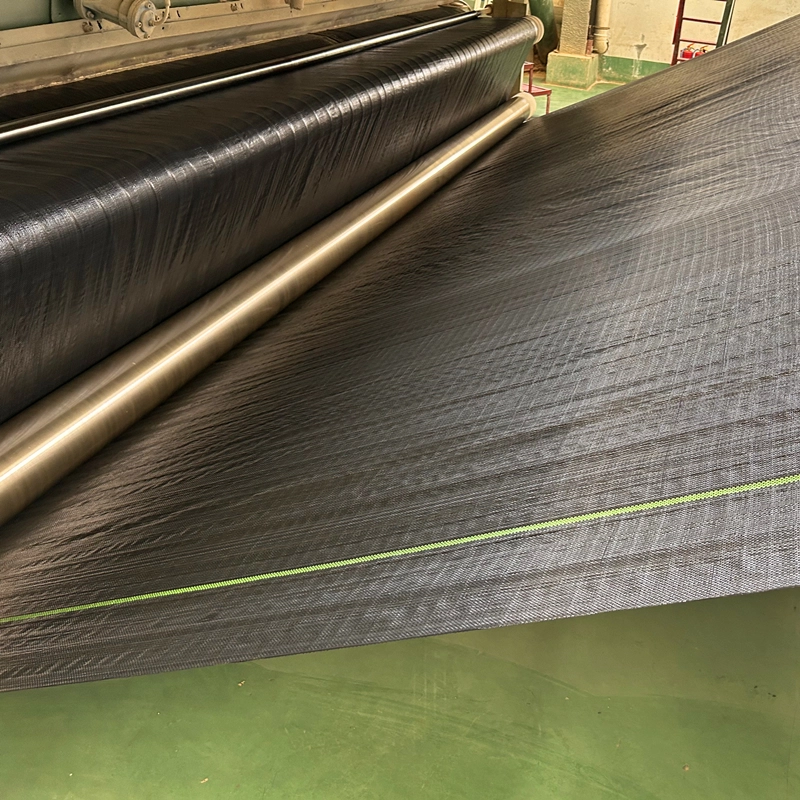

High Strength PP Woven Geotextile for Hydraulic Engineering

PP woven geotextile, a polypropylene-based fabric, serves as a fundamental component in Hydraulic Engineering projects. Its versatile properties contribute significantly to the stability and sustainability of various water-related structures.

Haoyang Environmental Co., Ltd. (Haoyang) is a leading provider of innovative solutions in geosynthetic materials. Established in June 2008, Haoyang has been at the forefront of research and development, manufacturing, and environmental engineering services. Among our extensive range of products, the High Strength PP Woven Geotextile is specifically designed for hydraulic engineering applications, offering unparalleled durability and performance in challenging environments.

PP woven geotextile for Hydraulic Engineering

High-strength polypropylene (PP) woven geotextiles are widely used in hydraulic engineering for various purposes due to their excellent mechanical properties, durability, and resistance to environmental factors. Here are some benefits and applications of high-strength PP woven geotextiles in hydraulic engineering:

◢ Benefits:

High Strength: These geotextiles possess excellent tensile strength and tear resistance, providing stability and reinforcement to hydraulic structures.

Durability: Resistant to biological degradation, chemicals, and ultraviolet (UV) exposure, ensuring long-term performance in harsh environmental conditions.

Permeability: Maintains good water permeability while preventing soil erosion, promoting drainage, and allowing water flow in hydraulic applications.

Filtration Properties: Effective filtration capabilities help in separating soil particles from water, preventing clogging and maintaining hydraulic efficiency.

Erosion Control: Used in erosion control applications to stabilize soil, protect embankments, slopes, and riverbanks against erosion caused by water flow.

Reinforcement: Provides soil stabilization, improving the load-bearing capacity of soft soils and preventing subsidence in hydraulic structures.

◢ Applications in Hydraulic Engineering:

Reinforcement of Dams and Embankments: Used to reinforce and stabilize soil structures, preventing erosion and enhancing stability in dam and embankment construction.

Riverbank and Coastal Protection: Applied to prevent soil erosion along riverbanks, shorelines, and coastal areas affected by water currents.

Drainage Systems: Used as a filtration and separation layer in drainage systems to facilitate water flow while preventing soil migration and clogging.

Canal Linings and Reservoirs: Installed as liners or protective barriers in canals, reservoirs, and ponds to control seepage, enhance stability, and reduce soil erosion.

Slope Stabilization: Applied on slopes and hillsides to prevent soil erosion, control surface water runoff, and stabilize the soil structure.

Road and Railway Construction: Used beneath roadways and railway tracks to enhance soil stability, reinforce subgrades, and improve overall infrastructure performance.

High-strength PP woven geotextiles play a crucial role in hydraulic engineering by providing reinforcement, erosion control, filtration, and stability in various construction projects involving water flow, soil stabilization, and environmental protection.

947713.webp)

Features

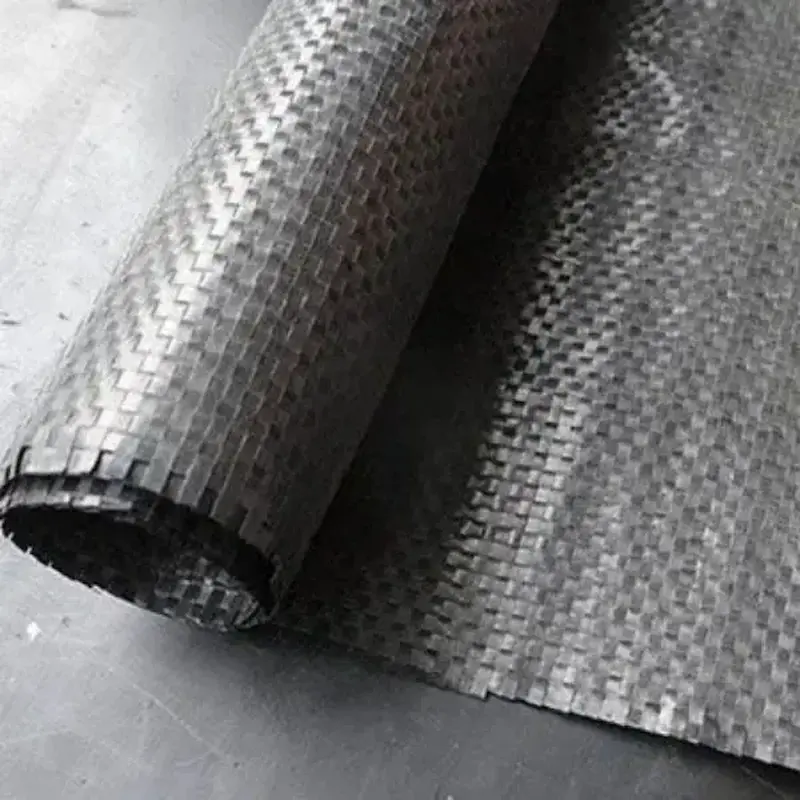

Principles:

Soil Stabilization and Separation: The geotextile's woven structure forms a stable layer, preventing the mixing of different soil types. It acts as a barrier, separating soil layers and reducing the risk of structural failure caused by soil erosion or movement.

Erosion Control:

PP woven geotextile effectively mitigates erosion along water channels, embankments, and riverbanks. Its robust design resists hydraulic forces, reducing surface erosion and maintaining structural integrity over time.

Filtration:

Utilized as a filtration medium, the geotextile permits water flow while trapping suspended particles. This function prevents soil loss, ensuring waterways remain clear and sediment-free, which is crucial for the efficiency and longevity of hydraulic structures.

Reinforcement:

By enhancing soil stability, PP woven geotextile fortifies the base of hydraulic structures like dams and reservoirs. It provides additional support to the soil, improving load-bearing capacity and overall structural strength.

189022.webp)

Specification

| Place of Origin | Shandong,China |

Brand Name | Haoyang |

Geotextile Type | Woven Geotextiles |

Type | Plastic woven film yarn geotextile |

Material | PP |

Color | Black,White,Green |

| Width | 1-6m |

Length | 50-100m/roll (at Request) |

Application | Separation/filtration/drainage/reinforcement/protection/liquid barrier |

Why Use Polypropylene Woven Geotextile?

Polypropylene woven geotextiles are commonly used in water conservancy projects due to their numerous beneficial properties and functionalities that contribute to the overall effectiveness and longevity of such projects. Here are several reasons why polypropylene woven geotextiles are favored in water conservancy projects:

Strength and Durability: Polypropylene woven geotextiles exhibit high tensile strength and durability, enabling them to withstand significant loads and resist damage caused by environmental factors, such as UV radiation, chemicals, and biological degradation.

Erosion Control: These geotextiles help prevent soil erosion along riverbanks, embankments, and other waterways by stabilizing soil particles and resisting the impact of water flow. They protect against the loss of soil and maintain structural integrity in these areas.

Filtration and Drainage: They function as effective filtration layers, allowing water to pass through while preventing soil particles from migrating. This property aids in maintaining proper drainage, reducing the risk of clogging and ensuring optimal water flow within the project area.

Stabilization of Soil: Polypropylene woven geotextiles reinforce and stabilize soil structures, enhancing their load-bearing capacity, reducing settlement, and preventing soil migration. This is crucial in water conservancy projects to maintain the stability of embankments, dams, and other hydraulic structures.

Versatility and Adaptability: These geotextiles are versatile and can be used in various applications within water conservancy projects, including lining canals, protecting reservoirs, reinforcing slopes, and controlling sediment runoff.

Cost-Effectiveness: They offer a cost-effective solution by providing long-term stability and reducing maintenance needs. Their durability and resistance to environmental degradation contribute to their cost efficiency over the project's lifespan.

Environmental Compatibility: Polypropylene geotextiles are environmentally friendly and do not deteriorate or release harmful substances into the surrounding environment, ensuring they meet environmental standards and regulations.

In summary, polypropylene woven geotextiles are chosen for water conservancy projects due to their ability to control erosion, provide soil stabilization, facilitate proper drainage, offer versatility, and deliver long-term durability while being cost-effective and environmentally compatible. These properties make them essential components in the successful execution of water management and conservation

Company Advantages

Haoyang is a high-tech enterprise recognized for its commitment to quality and innovation. Our certifications, including ISO 9001, ISO 14001, and OHSAS 18001, reflect our dedication to maintaining the highest standards in production and environmental management. We have been honored by the National Laboratory as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory," underscoring our leadership in the field.

With a professional technical R&D team, Haoyang continually invests in research and development to create advanced materials that meet the evolving needs of the industry. Our expertise in environmental engineering design, soil remediation, and waste treatment ensures that our products not only perform exceptionally but also contribute to sustainable and environmentally responsible solutions.

To learn more about our High Strength PP Woven Geotextile and how it can benefit your hydraulic engineering projects, please contact us.

257.webp)

383.webp)

272.webp)

502.webp)

503.webp)

759.webp)

482.webp)