Non-woven geotextiles are essential materials in various civil engineering, construction, and landscaping projects. They are used for purposes such as soil stabilization, erosion control, drainage, and filtration. Given their importance in such projects, understanding the cost of non-woven geotextiles is crucial for effective budgeting and planning. This article will explore the factors that influence the cost of non-woven geotextiles, provide an overview of typical prices based on different specifications, and explain how to calculate the amount needed for a project.

What is Non-Woven Geotextile?

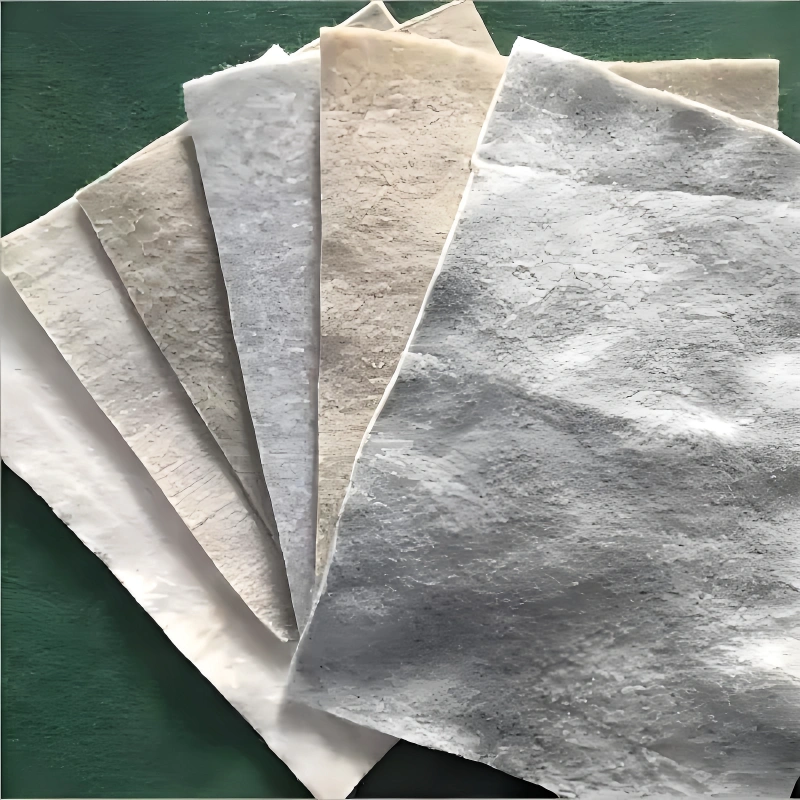

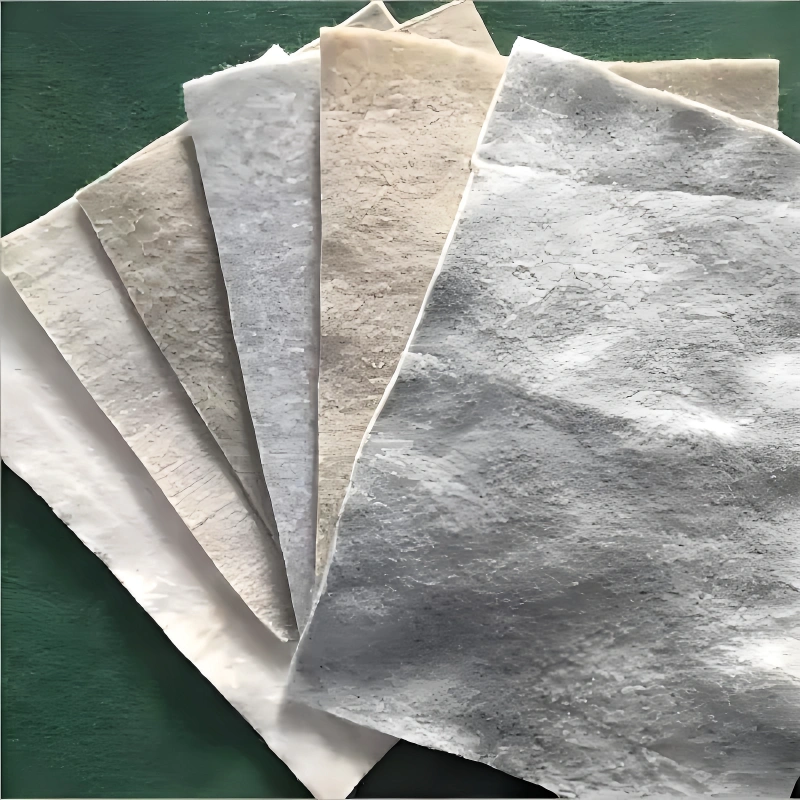

Non-woven geotextiles are made from synthetic fibers, typically polypropylene or polyester, that are bonded together through mechanical, chemical, or thermal processes. Unlike woven geotextiles, which have a distinct pattern due to their weaving process, non-woven geotextiles have a felt-like texture. They are known for their permeability, flexibility, and strength, making them ideal for applications where drainage and filtration are required.

Factors Influencing the Cost of Non-Woven Geotextile

The cost of non-woven geotextile can vary depending on several factors:

Material Type:

The type of synthetic fiber used (e.g., polypropylene or polyester) can affect the price. Polyester geotextiles tend to be more expensive due to their higher strength and durability.

Weight/Thickness:

Non-woven geotextiles come in various weights or thicknesses, typically measured in grams per square meter (gsm). Heavier geotextiles (e.g., 300 gsm and above) are more expensive but offer greater strength and durability.

Width and Roll Length:

The width and length of the geotextile roll can influence the price. Wider and longer rolls generally cost more due to the larger area of material provided.

Permeability:

Geotextiles with higher permeability rates, which allow water to pass through more easily, may be priced higher due to the specialized manufacturing processes involved.

Brand and Quality:

The brand and quality of the geotextile can also impact the price. Reputable brands that guarantee consistent quality may charge a premium compared to lesser-known or generic brands.

Quantity Purchased:

Bulk purchases often come with discounts. The cost per square meter can decrease significantly when larger quantities are ordered.

Typical Costs of Non-Woven Geotextiles

Here’s an overview of the typical costs for non-woven geotextiles based on different specifications:

| Weight/Thickness (gsm) | Approximate Cost per Square Meter (USD) | Applications |

|---|---|---|

| 100 gsm | $0.20 - $0.50 | Lightweight applications, such as landscaping |

| 150 gsm | $0.30 - $0.60 | Soil stabilization, light drainage |

| 200 gsm | $0.40 - $0.80 | Erosion control, subgrade stabilization |

| 300 gsm | $0.60 - $1.20 | Heavy-duty drainage, road construction |

| 400 gsm | $0.80 - $1.50 | High-strength applications, such as retaining walls |

Note: Prices can vary based on market conditions, location, and supplier. It's advisable to obtain quotes from multiple suppliers to get the best price for your specific needs.

How to Calculate the Amount of Non-Woven Geotextile Needed

To estimate the amount of non-woven geotextile required for your project, you can use the following formula:

Formula:

Total Area (㎡ )=Length (m)×Width (m)

Measure the Area:

Determine the length and width of the area where the geotextile will be applied. If the area is irregular, divide it into smaller, measurable sections and calculate the area of each section separately.

Add Overlap Allowance:

When laying down geotextile sheets, an overlap is required between adjacent sheets to ensure proper coverage and effectiveness. Typically, an overlap of 0.3 to 0.6 meters (1 to 2 feet) is recommended.

Overlap Area (㎡)=Overlap Length (m)×Overlap Width (m)×Number of Overlaps

3.Total Geotextile Area:

Add the overlap area to the total area to calculate the amount of geotextile needed.

Total Area (㎡)=Length (m)×Width (m)Total Geotextile Area (㎡)=Total Area (㎡)+Overlap Area (㎡ )

4. Calculate Number of Rolls:

Determine how many rolls of geotextile are needed by dividing the total geotextile area by the area covered by one roll.

Number of Rolls= Area per Roll (㎡)/Total Geotextile Area (㎡)

Example Calculation:

Suppose you need to cover an area of 100 meters by 50 meters using a 300 gsm non-woven geotextile with a roll size of 4 meters by 50 meters. The overlap allowance is 0.5 meters.

Area Calculation:

Total Area: 100m×50m=5000 ㎡

Overlap Calculation:

If you lay the geotextile in a pattern where each roll overlaps the next by 0.5 meters, and considering a 4-meter roll width:

Number of Overlaps: 100/(4−0.5) ≈28

Overlap Area: 0.5m×50m×28≈700㎡

Total Geotextile Area:

5000㎡ +700㎡ =5700㎡

Number of Rolls:

Each roll covers 4 m×50 m=200 ㎡

Number of Rolls:200㎡ /roll5700㎡ =28.5rolls

Round up to 29 rolls.

The cost of non-woven geotextiles can vary significantly based on the material, weight, and quality of the product. Understanding the factors that influence pricing and how to calculate the required amount can help you budget more effectively for your project. Whether you’re working on a small landscaping project or a large-scale construction site, non-woven geotextiles provide essential support for soil stabilization, erosion control, and drainage.

By following the calculation methods outlined in this article, you can ensure that you purchase the right amount of geotextile, minimizing waste and maximizing efficiency. Always consider obtaining quotes from multiple suppliers to get the best price and ensure that you choose a geotextile that meets the specific needs of your project.

About Haoyang Environmental

Haoyang Environmental is a leading manufacturer of Non-Woven Geotextiles based in China. With a strong commitment to quality and innovation, we specialize in producing high-performance geotextile products that are widely used in civil engineering, construction, and environmental projects. Our non-woven geotextiles are designed to provide excellent filtration, drainage, and reinforcement, making them ideal for a wide range of applications.

We offer comprehensive wholesale services, ensuring that our clients receive top-quality products at competitive prices. Additionally, Haoyang Environmental provides OEM services, allowing businesses to customize our geotextiles to meet their specific needs and branding requirements. With advanced manufacturing facilities and a dedicated team of experts, we ensure that every product meets international standards for quality and performance. Partner with Haoyang Environmental for reliable, cost-effective geotextile solutions tailored to your project needs.

897.webp)

942.webp)

237.webp)