Characteristics and Advantages of Geomembranes

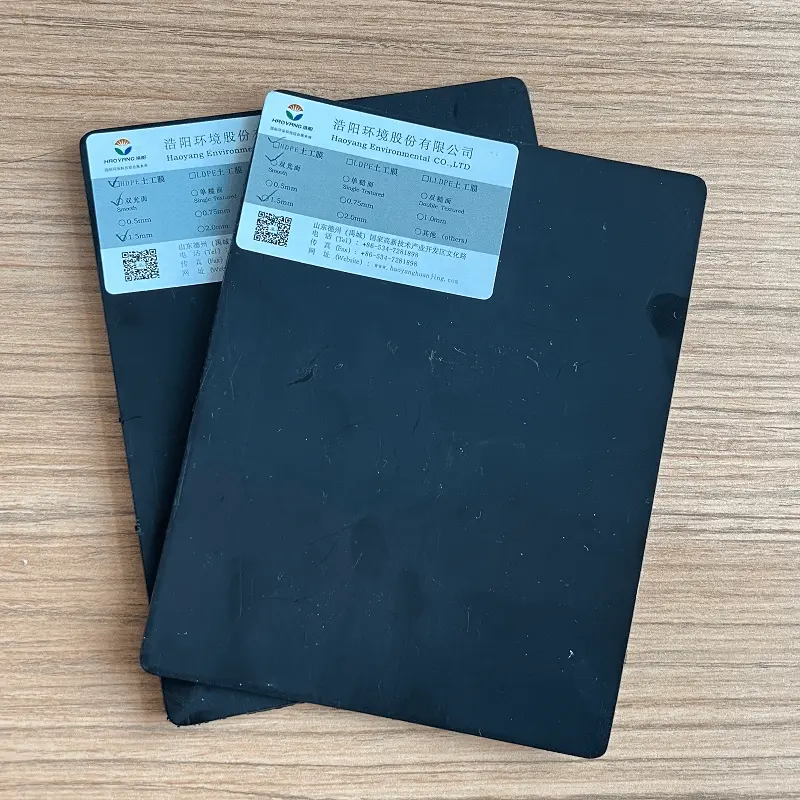

Geomembranes are high-polymer materials typically made of high-density polyethylene (HDPE) or polyvinyl chloride (PVC), featuring the following characteristics:

High Impermeability: Geomembranes have an extremely low permeability coefficient, effectively preventing the seepage of liquids or gases.

Chemical Resistance: They exhibit excellent resistance to most chemicals, including acids, alkalis, and oils.

UV and Aging Resistance: Geomembranes have excellent anti-oxidation and UV resistance, allowing prolonged exposure to sunlight without degradation.

High Mechanical Strength: They possess high tensile and tear resistance, making them suitable for various complex terrains.

Application Scenarios for Geomembranes

The extensive application of geomembranes stems from their superior performance. Below are some typical scenarios:

| Application Scenario | Description |

|---|---|

| Landfills | Used as a bottom liner to prevent leachate from contaminating groundwater. |

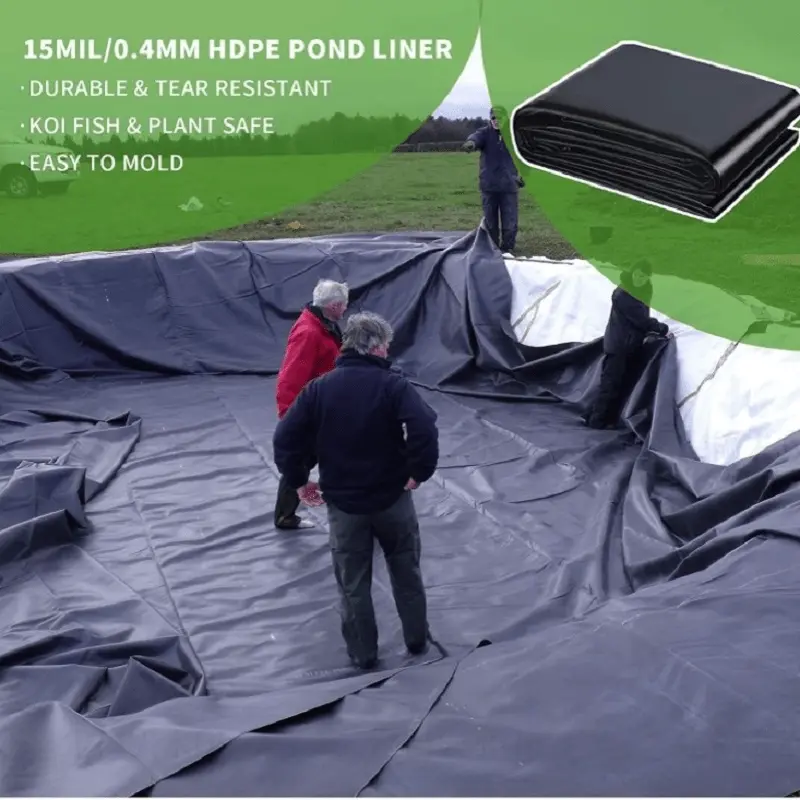

| Reservoirs and Artificial Lakes | Act as a waterproof liner to reduce water leakage and ensure resource utilization. |

| Tunnels and Underground Projects | Prevent groundwater seepage into structures, enhancing stability. |

| Chemical Ponds and Tailings Dams | Prevent chemical spills or slurry leakage, protecting the surrounding environment. |

| Roads and Railways | Prevent subgrade erosion and water seepage, strengthening subgrade stability. |

How to Choose the Right Geomembrane

Selecting the appropriate geomembrane material is crucial for project success. Key factors include:

Material Thickness: Choose the appropriate thickness based on project needs. For instance, landfills often require HDPE geomembranes of 1.5mm or thicker, while artificial lakes may only need 0.5mm.

Environmental Conditions: Consider the temperature, UV intensity, and chemical exposure of the project site to select adaptive materials.

Mechanical Strength: Ensure the material has sufficient tensile and tear resistance to withstand potential external forces.

Certifications and Standards: Opt for products that comply with national or international standards (e.g., ISO 9001 or ASTM standards) to ensure quality and reliability.

Installation Methods for Geomembranes

Proper installation is critical to the performance and longevity of geomembranes. Key points to consider during installation include:

Site Preparation: Ensure the foundation is smooth, dry, and free of sharp objects to prevent puncturing the geomembrane.

Seaming Techniques: Use thermal welding or adhesive techniques for seams to ensure tight sealing.

Compaction and Protection: Lay a protective layer (e.g., nonwoven fabric or fine sand) over the geomembrane to prevent mechanical damage.

Quality Inspection: Perform air tightness or vacuum tests to check for leaks at the seams.

Enhancing Project Durability with Geomembranes

Data Support

Below is a comparison of project durability before and after using geomembranes:

| Project Type | Average Lifespan Before Using Geomembranes (Years) | Average Lifespan After Using Geomembranes (Years) | Improvement (%) |

| Landfills | 10 | 50 | 400% |

| Reservoirs and Lakes | 15 | 40 | 167% |

| Tunnel Projects | 20 | 60 | 200% |

| Road Subgrades | 10 | 30 | 200% |

Principle Analysis

Reduced Leakage: The high impermeability of geomembranes prevents water or chemical seepage, protecting project foundations.

Delayed Aging: Geomembranes shield foundational materials from environmental degradation such as oxidation, erosion, and chemical reactions, extending their lifespan.

Enhanced Structural Stability: They prevent foundation moisture loss or excessive saturation, maintaining stability and load-bearing capacity.

Conclusion

As a highly efficient impermeable material, geomembranes excel in enhancing the durability of engineering projects. By selecting suitable materials, employing proper installation techniques, and conducting regular maintenance, geomembranes can significantly extend project lifespans and reduce long-term operational costs. In future engineering practices, geomembranes have promising prospects, contributing to sustainable development.

![]() 1.5 Double-sided smooth HDPE geomembrane.pdf

1.5 Double-sided smooth HDPE geomembrane.pdf

897.webp)

942.webp)

237.webp)