Geomembrane welding machine is a piece of equipment specifically used for geomembrane welding. It is usually used to join two or more geomembrane sheets together to form a continuous, impermeable isolation layer. These devices usually have adjustable temperature and pressure controls to ensure the melting and joining quality of the mulch material during the welding process. Choosing the correct welding machine is essential to achieve reliable and durable seams. First, let’s take a look at what geomembrane welding machine is and its types.

Geomembrane wide width welding machine

Geomembrane narrow width welding machine

1. Types of geomembrane welding machine

Geomembrane welding machine is a device used to weld geomembranes. It can usually be divided into the following types according to different welding technologies and application scenarios:

(1) Hot air welding machine: Use hot air to heat two geomembranes to a molten state, and then connect them together through pressure. This method is suitable for thinner geomembranes and larger area welding.

(2) Hot wedge welding machine: The geomembrane is heated to a molten state by heating the welding wedge, and then the two geomembranes are connected together. This method is suitable for thicker geomembranes and smaller area welding.

(3) Extrusion welding machine: Extrude the geomembrane material into a strip, and apply heat to the extruded geomembrane to melt it and form a strong connection between the two geomembranes.

(4) Electric hot melt welding machine: Heating the edge of the geomembrane through electric current to melt it, and applying pressure while heating to ensure a firm connection.

2. Welding detail analysis usually includes the following aspects

(1) Temperature control: According to the type and thickness of the geomembrane material, set the temperature of the welding machine reasonably to ensure that the geomembrane can be properly heated to a molten state.

(2) Pressure control: Apply appropriate pressure during the welding process to ensure a firm connection between the geomembranes and prevent bubbles or gaps from appearing.

(3) Welding speed: Control the moving speed of the welding machine to ensure that the heating time and pressure of the geomembrane are evenly distributed during the welding process, thereby obtaining high-quality welded joints.

(4) Welded joint design: Design appropriate welded joint forms, such as overlapped, covered or slotted connections, to ensure good sealing and durability of the welded joint.

(5) Inspection and quality control: After the welding is completed, conduct joint quality inspection to ensure that the welded joint meets the specification requirements, and take necessary repair measures to ensure that the welding quality meets the standards.

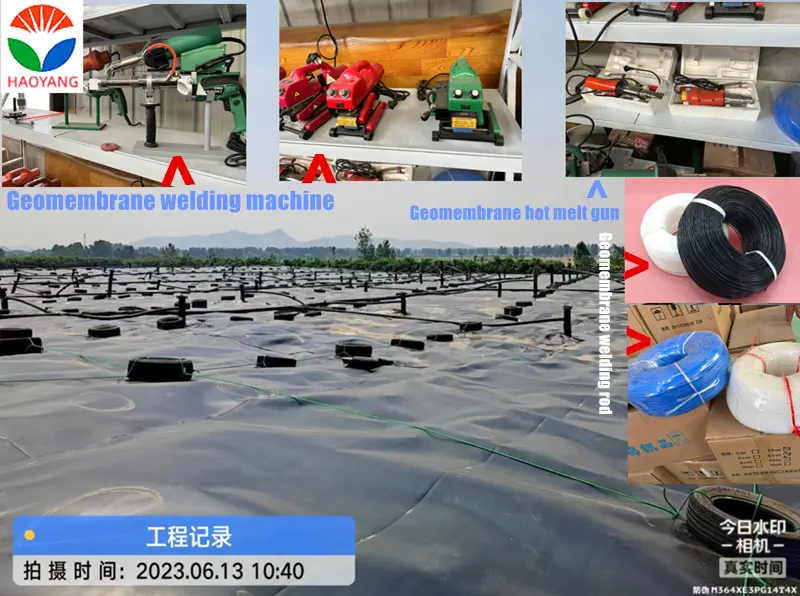

Geomembrane welding rod: white and black

Geomembrane welding rod: white and blue

3. Key factors when choosing a welding machine

When selecting a geomembrane welding machine, multiple factors need to be considered to ensure that the selected machine can meet project needs and achieve efficient welding results. Here are some key factors when choosing a welding machine:

(1) Welding technology and type: According to the project requirements and the material of the geomembrane, select the appropriate welding technology and type, such as hot air welding, hot wedge welding, extrusion welding, etc.

(2) Welding width: Consider whether the maximum welding width of the welding machine can meet the project needs to ensure that the required geomembrane width can be processed.

(3) Temperature and pressure control: The welding machine should have adjustable temperature and pressure control functions to adapt to different types and thicknesses of geomembranes and ensure good welding results.

(4) Mobility and portability: According to the specific conditions of the project, consider the mobility and portability of the welding machine so that it can be used flexibly between different work sites.

(5) Ease of operation: Choose a welding machine that is easy to operate, easy to learn and use, to reduce operator training costs and time.

(6) Durability and reliability: Choose a welding machine with reliable quality, solid structure, and good durability to ensure long-term stable working performance and reliable welding quality.

(7) After-sales service and technical support: Consider whether the after-sales service and technical support provided by the supplier are timely and reliable to ensure that problems can be solved in a timely manner and support can be obtained during use.

Take the above factors into consideration and select a suitable geomembrane welding machine according to specific project needs and budget to ensure the smooth progress of the project and high-quality welding results.

Geomembrane hot melt gun

4. Application

Geomembrane welding machines are widely used in many fields, including:

(1) Water conservancy projects: used for anti-seepage treatment in reservoirs, rivers, canals, reservoirs and other water conservancy projects to ensure the sealing and safety of water bodies.

(2) Environmental engineering: used for anti-seepage treatment in environmental projects such as landfills, sewage treatment plants, hazardous waste treatment sites, etc. to prevent the contamination of soil and groundwater by harmful substances.

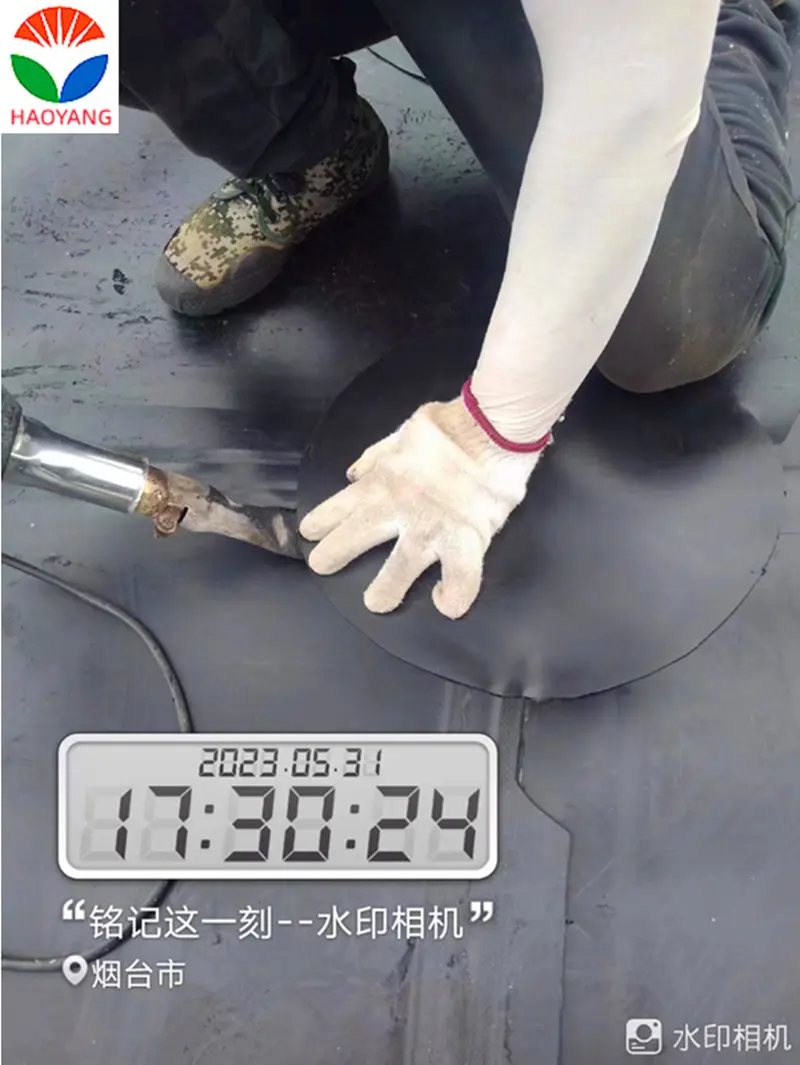

The welding process of Haoyang Environmental Co., Ltd. during geomembrane construction

(3) Road and bridge engineering: used for anti-seepage treatment in highways, railways, bridges and other projects to ensure the stability of the foundation soil and the safety of the engineering structure.

(4) Mining engineering: used for anti-seepage treatment in underground projects such as mines and mines to prevent the leakage of harmful substances and the pollution of groundwater resources.

(5) Construction engineering: Used for waterproofing treatment in buildings, basements, underground pipelines and other construction projects to ensure the dryness of the building and the safety of the structure.

(6) Agricultural engineering: Used for anti-seepage treatment in agricultural projects such as pools, channels, and reservoirs to ensure the effectiveness of farmland irrigation and water resources management.

(7) Garden and landscape projects: Used for anti-seepage treatment in garden landscape projects such as parks, scenic spots, golf courses, etc. to ensure the beauty of the landscape and the cleanliness of the water body.

(8) Coastal and flood control projects: used for anti-seepage treatment in coasts, dams, flood control walls and other coastal and flood control projects to protect the integrity of coastlines and flood control facilities.

To sum up, geomembrane welding machines have important applications in various engineering fields, providing important guarantees for the safety, stability and sustainability of projects.

Choosing the right geomembrane welding machine is crucial for achieving high-quality and durable seams in containment systems. By understanding your project application requirements, evaluating welding techniques, considering machine features and specifications, prioritizing quality and reliability, and budget considerations, you can make an informed decision that meets your needs and ensures successful project outcomes.

897.webp)

942.webp)

237.webp)