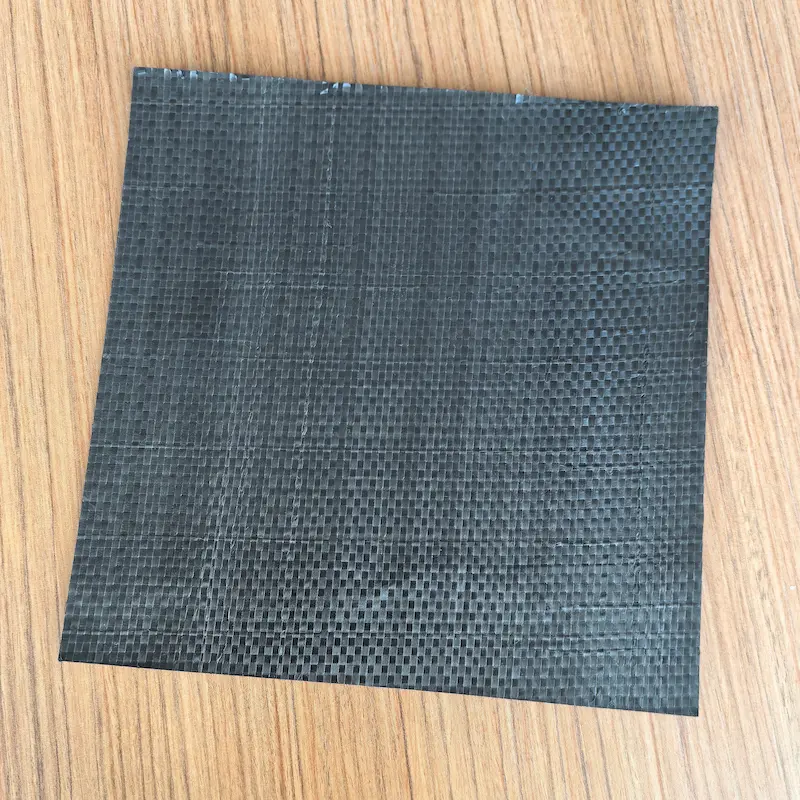

Material Composition of Plastic Woven Film Yarn Geotextile

The production of plastic woven film yarn geotextile for building construction involves meticulous selection and preparation of materials. This geotextile primarily comprises polyethylene or polypropylene, chosen for their durability and resilience. These raw materials undergo an extrusion process where the plastic resin is melted and then extruded into flat film yarns. These yarns are carefully woven into a stable fabric through a weaving process, creating a robust and flexible geotextile material.

Discover the superior performance of Plastic Woven Film Yarn Geotextile from Haoyang Environmental Co., Ltd., your trusted partner in environmental solutions. Engineered with precision and innovation, our geotextile is designed to enhance stability, durability, and sustainability in construction projects of all scales.

517031.webp)

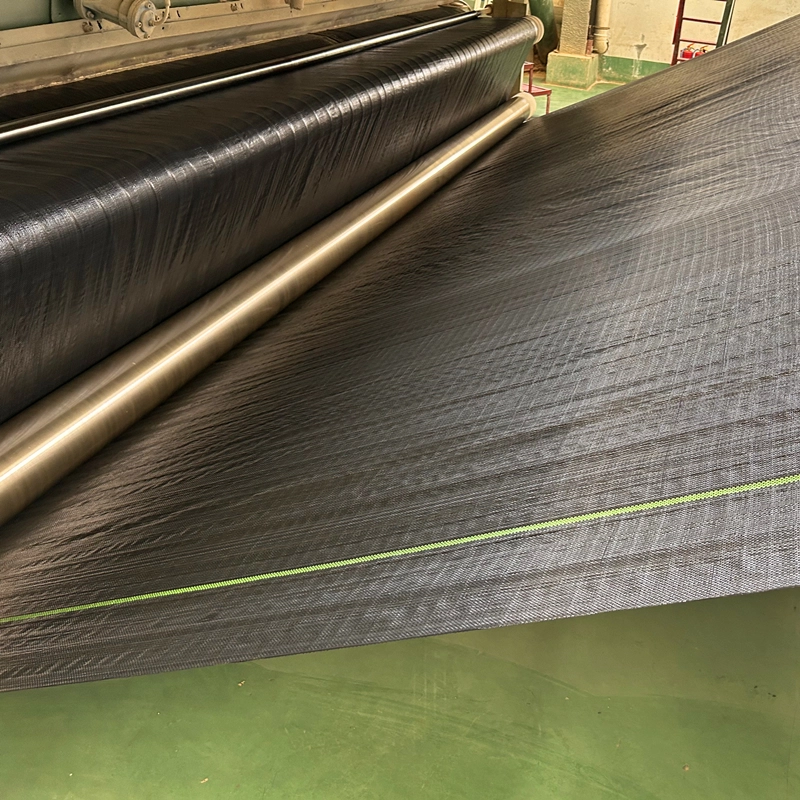

Manufacturing Process

The manufacturing process of plastic woven film yarn geotextile involves several key steps. Initially, the selected polymer pellets undergo melting in an extruder, transforming them into a molten form. This molten material is then passed through a specialized spinneret to create fine strands of yarn. These yarns are stretched and cooled to attain the desired strength and thickness.

Subsequently, the woven fabric is formed by interlacing these film yarns using high-speed weaving machines. This weaving process meticulously intertwines the yarns in a stable and uniform manner, forming a resilient geotextile sheet. Post-weaving, the geotextile undergoes treatments like heat setting and calendaring to enhance its mechanical properties and ensure uniformity in its structure.

324843.webp)

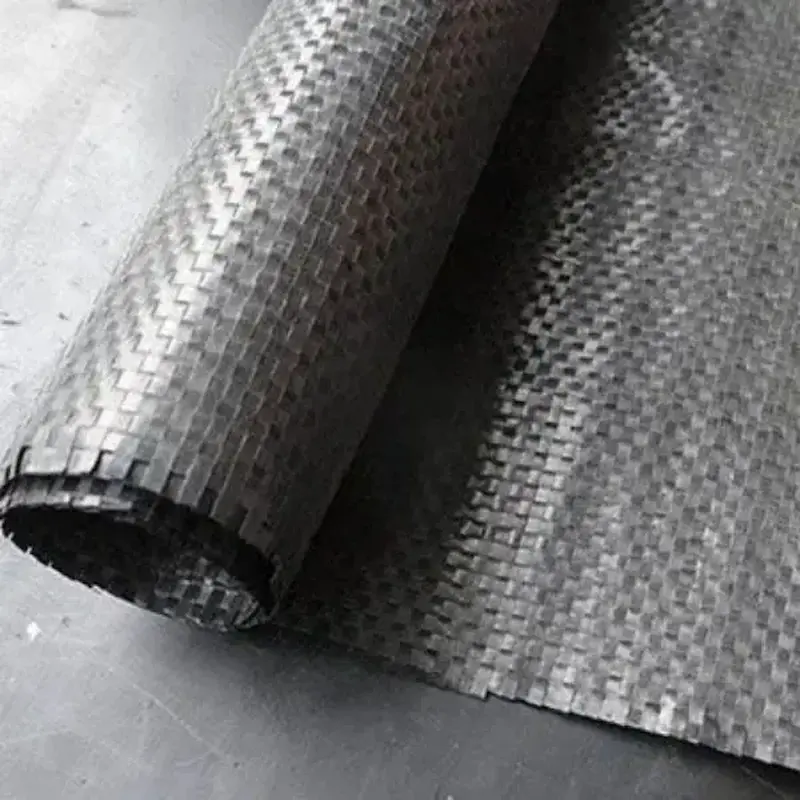

Role in Building Construction

In building construction, plastic woven film yarn geotextile serves various crucial functions. It is commonly used as a separator between different soil layers to prevent mixing, ensuring proper drainage and stability. Additionally, it reinforces soil structures, serving as a stabilizing agent in retaining walls, embankments, and erosion control measures. The geotextile's high tensile strength and resistance to environmental factors make it an indispensable material for ensuring the longevity and integrity of diverse construction projects.

Specification

| Place of Origin | Shandong,China |

Brand Name | Haoyang |

Geotextile Type | Woven Geotextiles |

Type | Plastic woven film yarn geotextile |

Material | PP/PE |

Color | Black,White,Green |

Width | 1-6m |

Length | 50-100m/roll (at Request) |

Application | Separation/filtration/drainage/reinforcement/protection/liquid barrier |

Product Advantages

High Strength and Durability: Our geotextile is crafted from high-quality plastic woven film yarn, ensuring exceptional tensile strength and resilience against environmental stressors.

Superior Filtration and Drainage: Designed to facilitate efficient water flow while preventing soil erosion, enhancing soil stability and structural integrity.

UV Resistance and Longevity: Resistant to UV radiation and chemicals, maintaining integrity and functionality over extended periods of exposure.

Company Advantages

Expertise and Innovation: With over a decade of industry leadership, Haoyang Environmental Co., Ltd. pioneers geosynthetic material research and development, backed by a dedicated R&D team and state-of-the-art facilities.

Certified Quality and Compliance: Accredited with ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring stringent quality management, environmental responsibility, and occupational health and safety standards compliance.

Technological Prowess: Recognized as a Shandong Enterprise Technology Center and Environmental Protection New Materials Engineering Laboratory, we hold multiple patents and provincial-level scientific accolades for groundbreaking innovations.

Contact Us

Plastic woven film yarn geotextile, derived from carefully selected raw materials and crafted through a precise manufacturing process, plays an indispensable role in enhancing the durability, stability, and resilience of building construction projects.

Explore the possibilities with Haoyang Environmental Co., Ltd. and elevate your construction projects with our Plastic Woven Film Yarn Geotextile. For inquiries, customized solutions, and partnership opportunities, contact us today.

732.webp)

548.webp)

743.webp)

503.webp)

759.webp)

482.webp)