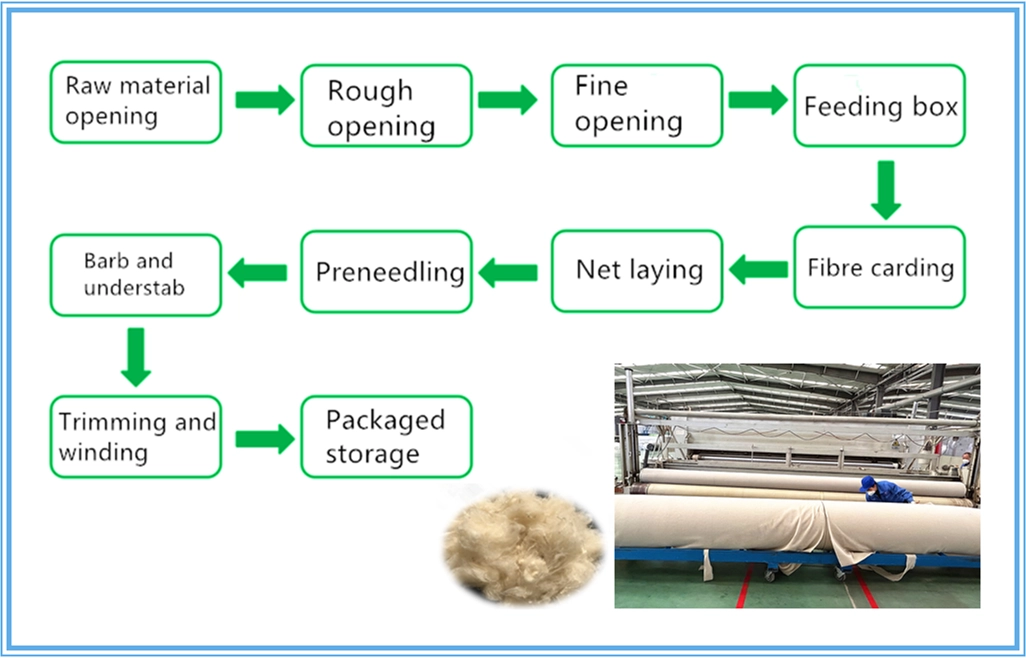

2、How is staple fiber non-woven geotextile produced?

(1) Raw material unpacking: After unpacking, observe the appearance of raw materials and whether there are other debris.

(2) Raw material loosening: The role of loosening is to change the raw material from large pieces to small pieces or fiber bundles.

(3) Cotton feeding box: The fiber is fully opened and mixed into uniform 筳 cotton fed to the carder.

(4) Fiber carding: The role of the carding machine is to process the fibers through the opening process into a thin fiber net, and after laying and crossing into a net, for the acupuncture machine reinforcement.

(5) Mesh laying: The single-layer fiber net output by the carding machine needs to be repeatedly stacked through the mesh laying mechanism to achieve the product's required unit area quality and width.

(6) Acupuncture: The role of the acupuncture machine is to initially wind and finalize the fiber net formed by combing and laying the net to meet certain technological requirements, reduce the drafting of the formed fiber net as much as possible, and ensure that the direction of the fiber net of the fibril net is unchanged to achieve the best result of the product.

(7) Trimming and winding and finished product packaging.

6、Staple fiber punched geotextile application field:

Widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering. Can meet a variety of different uses. It takes advantage of the industrial and low-cost advantages of synthetic fibers; High strength, low elongation, durability, corrosion resistance; The woven fabric has the characteristics of stable structure and high compliance rate of engineering parameters, which can meet the requirements of reverse filtration, isolation, reinforcement and protection for different purposes of geotechnical engineering. It is a kind of high value products in geotechnical engineering.

1、Product introduction

Geotextile is a kind of nonwoven and industrial cloth, which is made of polyester crimped staple fiber with fiber density of 6-12 denier and length of 54-64mm.

Through the non-woven production equipment opening, combing, clutter (short fibers interwoven together), laying nets (standardized entanglement fixed), acupuncture and other production processes to make cloth. It is used in railway roadbed reinforcement, highway pavement maintenance, sports hall, dam protection, hydraulic construction isolation, tunnel, coastal beaches, reclamation, environmental protection and other projects.

2、How is staple fiber non-woven geotextile produced?

(1) Raw material unpacking: After unpacking, observe the appearance of raw materials and whether there are other debris.

(2) Raw material loosening: The role of loosening is to change the raw material from large pieces to small pieces or fiber bundles.

(3) Cotton feeding box: The fiber is fully opened and mixed into uniform 筳 cotton fed to the carder.

(4) Fiber carding: The role of the carding machine is to process the fibers through the opening process into a thin fiber net, and after laying and crossing into a net, for the acupuncture machine reinforcement.

(5) Mesh laying: The single-layer fiber net output by the carding machine needs to be repeatedly stacked through the mesh laying mechanism to achieve the product's required unit area quality and width.

(6) Acupuncture: The role of the acupuncture machine is to initially wind and finalize the fiber net formed by combing and laying the net to meet certain technological requirements, reduce the drafting of the formed fiber net as much as possible, and ensure that the direction of the fiber net of the fibril net is unchanged to achieve the best result of the product.

(7) Trimming and winding and finished product packaging.

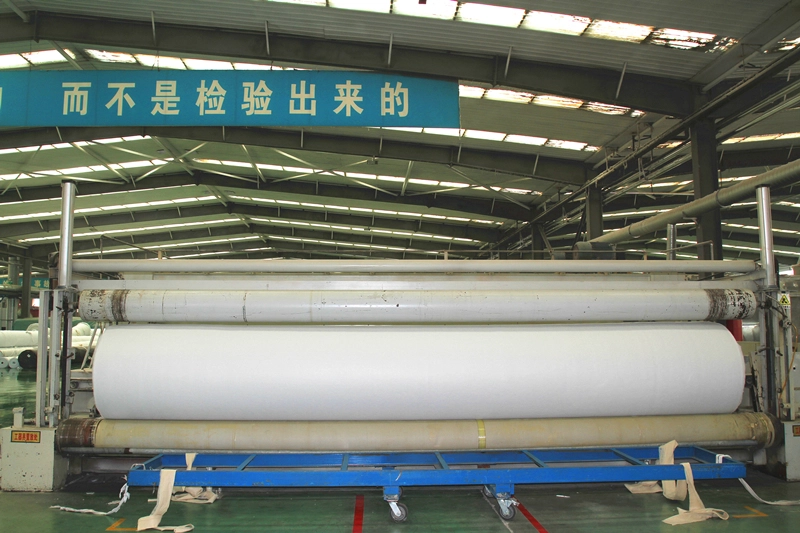

3、Production workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

4、Short fiber needled nonwoven geotextile quality technical index

The technical requirements of the basic internal quality of geosynthetic materials staple fiber needled nonwoven geotextiles are shown in the table, which conforms to the new national standard GB/T 17638-2017 in China.

No. | Item | Unit | Nominal breaking strength | ||||||||

3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | |||

1 | Longitudinal and transverse fracture strength | Kn/m | ≧3.0 | ≧5.0 | ≧ 8.0 | ≧10.0 | ≧15.0 | ≧20.0 | ≧25.0 | ≧30.0 | ≧40.0 |

2 | Nominal breaking strength corresponds to elongation | % | 20~100 | ||||||||

3 | Bursting force | Kn | ≧0.6 | ≧1.0 | ≧1.4 | ≧1.8 | ≧2.5 | ≧3.2 | ≧4.0 | ≧5.5 | ≧7.0 |

4 | Mass deviation rate per unit area | % | ±5 | ||||||||

5 | Width deviation rate | % | -0.5 | ||||||||

6 | Thickness deviation rate

| % | ±10 | ||||||||

7 | Equivalent aperture O90(O95) | mm | 0.07-0.20 | ||||||||

8 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) ,K=1.0~9.9 | ||||||||

9 | Vertical and horizontal tearing force | Kn | ≧ 0.10 | ≧ 0.15 | ≧ 0.20 | ≧ 0.25 | ≧ 0.40 | ≧ 0.50 | ≧ 0.65 | ≧ 0.80 | ≧ 1.00 |

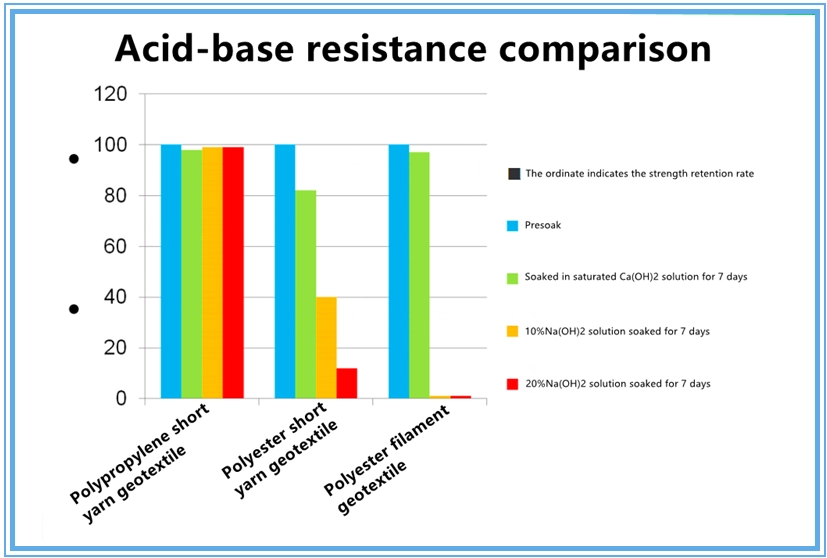

10 | Acid and alkali resistance (Strength guarantee ratio) | % | ≧80 | ||||||||

11 | Antioxidant property(Strength guarantee ratio) | % | ≧80 | ||||||||

12 | Ultraviolet resistance(Strength guarantee ratio) | % | ≧80 | ||||||||

5、Construction site display

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

6、Staple fiber punched geotextile application field:

Widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering. Can meet a variety of different uses. It takes advantage of the industrial and low-cost advantages of synthetic fibers; High strength, low elongation, durability, corrosion resistance; The woven fabric has the characteristics of stable structure and high compliance rate of engineering parameters, which can meet the requirements of reverse filtration, isolation, reinforcement and protection for different purposes of geotechnical engineering. It is a kind of high value products in geotechnical engineering.

7、Mode of transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

8、FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q2: Where is your factory located? How do I get there?

A2: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q3: Could you please send the sample before confirming the order?

A3: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q4: What are the specifications and sizes of this geotextile?

A4: We offer a wide selection of specifications and sizes, which can be customized according to the needs of the project, such as different widths, lengths and thicknesses.

Q5: How water and air permeability is it?

A5: The water permeability and air permeability of short silk non-woven needled geotextile will affect its effectiveness in drainage and protection, and it generally has good water permeability, so that water can flow freely.

Q6: What are the considerations for applicability in specific engineering projects?

A6: We will recommend geotextiles of appropriate specifications according to the engineering needs and environmental characteristics of our customers to ensure the best performance in a specific engineering project.

Q7: How about the production process and quality control of the product?

A7: Our short yarn non-woven needled geotextile adopts advanced production technology, and carries out strict quality control in the production process to ensure stable and reliable product quality.

Q8: What are the special advantages of this product in terms of protection and soil protection?

A8: Short filament non-woven needled geotextiles have good tensile resistance and wear resistance in terms of protection, and can effectively protect soil and prevent erosion.

Q9: What should I pay attention to in terms of installation methods and details?

A9: During the installation process, it is necessary to ensure that the geotextile is smooth and firm, avoid sharp scratches, and pay attention to the treatment of the joints to ensure tightness and stability.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

509.webp)

769.webp)