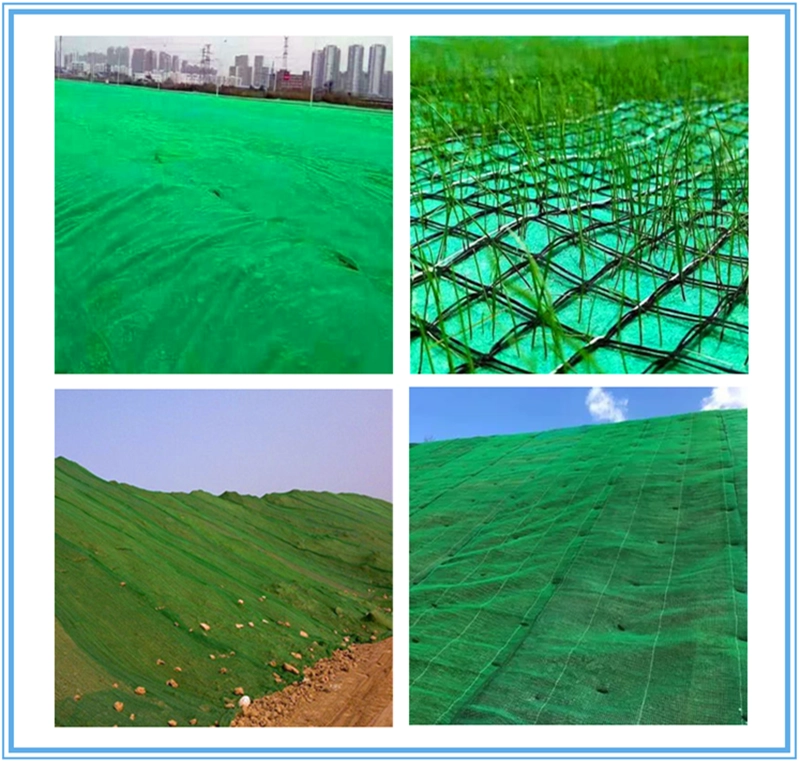

Special Green Plastic Flat Wire Woven Geotextile for Environmental Protection

Introducing Haoyang Environmental Co., Ltd.'s Special Green Plastic Flat Wire Woven Geotextile, designed to meet the growing demands of environmental protection and sustainable development. This innovative geotextile product is engineered from high-quality, eco-friendly materials, offering unparalleled strength and durability for various environmental applications. Our geotextile solutions are ideal for soil stabilization, erosion control, and filtration, ensuring a greener future while effectively managing environmental challenges.

Plastic Flat Wire Woven Geotextile

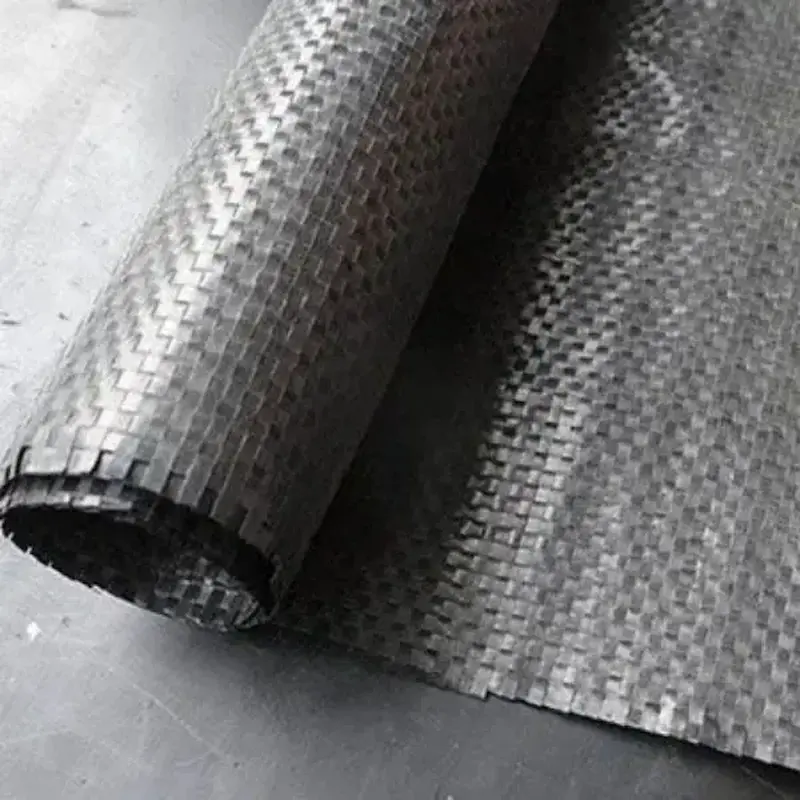

Plastic flat wire woven geotextile is a geosynthetic material made of polypropylene (PP) and other plastic materials. This geotextile is made by weaving flat plastic silk threads, has excellent strength and durability, and has a wide range of applications in civil engineering and construction.

It has good tensile strength and durability, and can resist environmental pressure and mechanical forces; It can also act as an efficient filter, allowing water to pass through while preventing the flow of soil particles, helping to separate the soil and prevent erosion; This geotextile facilitates efficient drainage and is widely used in projects that require water flow management, such as road construction, retaining walls and drainage systems. It is widely used in road and pavement construction, railway and airport runway projects, erosion prevention and slope stabilization, retaining wall and embankment construction, landfill liners and drainage systems. Plastic flat wire woven geotextiles provide robust support, erosion prevention and enhancement in civil engineering. Their durability and customizability make them indispensable materials in a variety of infrastructure construction and environmental protection projects.

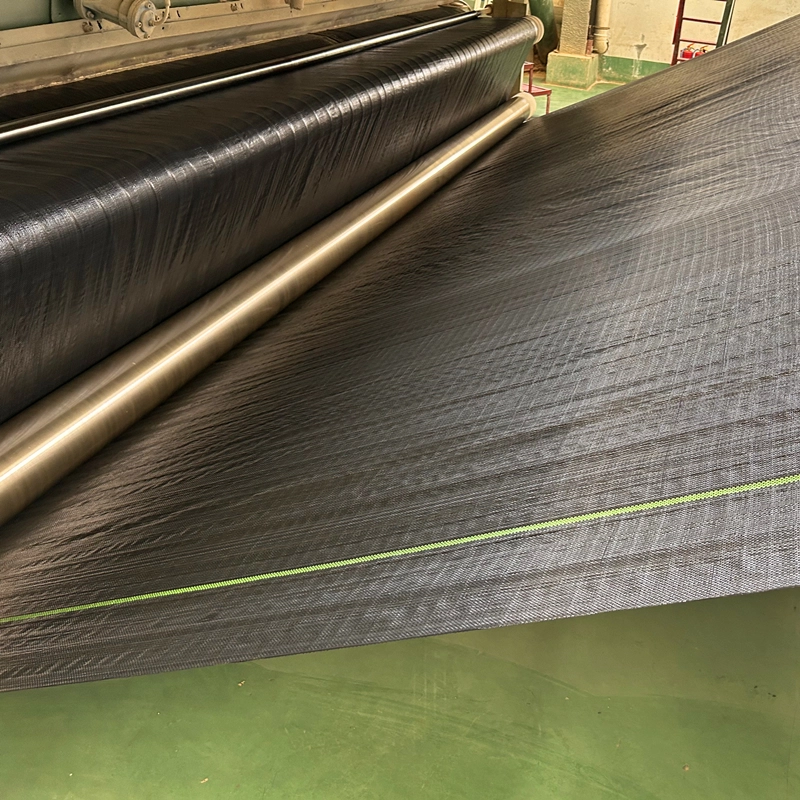

Our company mainly produces black and green plastic flat wire woven geotextiles, and is one of the main suppliers in China's South-to-North water diversion project.

Green Plastic Woven Film Yarn Geotextile Advantages And Characteristics

(1) Filtration and isolation: geotextiles can be used as a filter layer to allow water to pass through while effectively preventing the flow of soil particles, helping to separate the soil and prevent erosion.

(2) Easy installation and handling: geotextiles are usually lightweight and flexible, easy to cut and install, and can adapt to different shapes of terrain or building structures.

(3) Good corrosion resistance and chemical properties: they have strong resistance to acid and alkali, chemical substances and ultraviolet light, which helps to maintain long-term performance and stability.

(4) Environmental protection and recyclability: geotextiles are usually made of plastic materials, which can be recycled and reused to reduce the environmental burden.

(5) With high strength and durability: flat wire woven structure gives geotextile excellent tensile strength and durability, which helps to resist external pressure and lasting use.

In summary, green plastic flat wire preparation geotextiles are widely used in road construction, soil erosion prevention, drainage systems, underground engineering and environmental protection and other fields, is an important material for geoengineering.

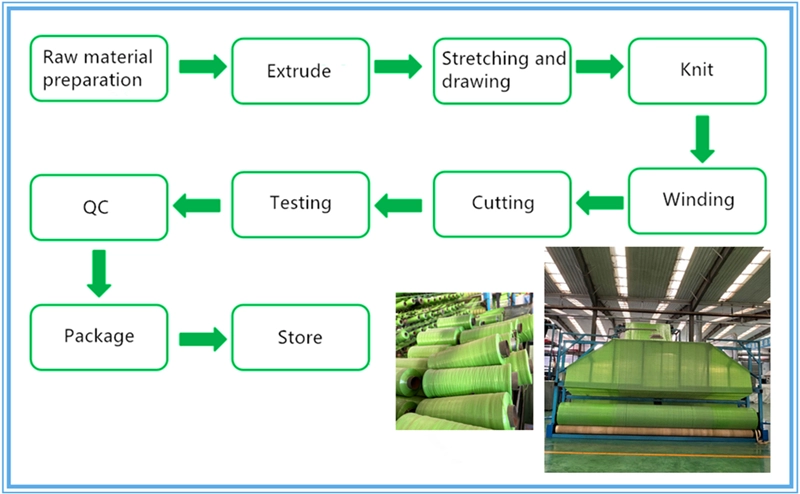

The Production Process Of Plastic Flat Wire Preparation Geotextile

The production process of plastic flat wire preparation geotextile is roughly as follows:

(1) Raw material preparation: The production process begins with the preparation of plastic particles, usually polypropylene (PP) or other plastic materials suitable for weaving. These particles are fed into an extruder.

(2) Extrusion: In the extruder, plastic particles are heated and extruded into a molten plastic liquid. This liquid is passed through a mold or extrusion head to form a thin, flat plastic sheet or strip film.

(3) Stretching and drawing: the plastic sheet or strip film is stretched and drawn to make it a flat plastic wire. These threads help to weave and strengthen geotextiles.

(4) Weaving: The flat plastic wire is cross-woven through the braiding machine. This process forms a strong fabric structure in which flat filaments are interwoven to form the flat structure of the geotextile. Our company has a number of preparation equipment, can prepare various sizes of flat wire woven geotextiles to meet customer needs.

(5) Winding and cutting: After the weaving is completed, the geotextile is rolled or cut to the appropriate size and length. Flat woven geotextiles of different widths and lengths can be cut according to the requirements.

(6) Inspection and quality control: the geotextile will leave the factory after sampling inspection by the company's testing center and meet the national standards and requirements. Tests usually include tensile strength, thickness uniformity, and braiding quality.

(7) Packaging and storage: the geotextile that has passed the inspection is properly packaged and ready to be sold or stored. They are usually stored in roll or board form for easy transportation and use.

These steps constitute the production process of the plastic flat wire woven geotextile, ensuring that the final product has the required strength, durability and quality standards.

Production Workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

Plastic Woven Film Yarn Geotextile Index

This performance index is suitable for polypropylene (PP), polyethylene (PE) as the main raw materials, through extrusion, film cutting, stretching to make flat yarn (monofilament, split film yarn) after preparation of geotextile. Meet the national standard GB/T17690-1999.

No. | Item | Unit | Index | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |||

1 | Warp breaking strength | Kn/m | ≧20 | ≧30 | ≧40 | ≧50 | ≧60 | ≧80 | ≧100 |

2 | Latitude breaking strength | Kn/m | ≧15 | ≧22 | ≧28 | ≧35 | ≧42 | ≧56 | ≧70 |

3 | Elongation at break at warp and latitude | % | 28 | ||||||

4 | Trapezoidal tearing strength (longitudinal) | Kn | ≧0.3 | ≧0.45 | ≧0.5 | ≧0.6 | ≧0.75 | ≧1.0 | ≧1.2 |

5 | Bursting strength | Kn | ≧1.6 | ≧2.4 | ≧3.2 | ≧4.0 | ≧4.8 | ≧6.0 | ≧7.5 |

6 | Vertical permeability coefficient | cm/s | 10-1~10-4 | ||||||

7 | Equivalent aperture O95 | mm | 0.08~0.5 | ||||||

8 | Mass per unit area | g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Allowable deviation value | % | ±10 | ||||||

10 | Uv resistance strength retention rate | % | ≧Design or contract requirements | ||||||

Company Advantages

Haoyang Environmental Co., Ltd. has been at the forefront of geosynthetic material innovation since 2008. Our commitment to quality is evidenced by our ISO 9001, ISO 14001, and OHSAS 18001 certifications, ensuring our products meet the highest international standards. Our dedicated R&D team continually advances our technology, boasting three invention patents and 32 utility model patents. Recognized as a leading enterprise in environmental technology, we pride ourselves on our expertise in environmental engineering consulting and comprehensive waste treatment solutions.

Ready to enhance your environmental projects with our Special Green Plastic Flat Wire Woven Geotextile? For more information, samples, or to discuss your specific needs, please reach out to us.

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

FAQ

Q1: What are its main uses?

A1: It is used in soil separation, erosion prevention, drainage system, road construction and other projects, can be used as a protective layer or road construction material.

Q2: Can the size and thickness of this geotextile be customized?

A2: Yes, we offer a variety of specifications and size options, which can be customized according to the needs of the project.

Q3: What should I pay attention to during installation and use?

A3: During installation, ensure that the geotextile is laid smoothly, connected firmly, and avoid damage to sharp objects. For specific projects, professional installation is recommended.

Q4: Is this geotextile environmentally friendly?

A4: Plastic flat wire woven geotextiles can be recycled, meet environmental standards, and still maintain stable performance after long-term use.

Q5: How do you guarantee the quality testing of your products?

A5: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Q6: Are you a factory or a trading company?

A6: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q7: Where is your factory located? How do I get there?

A7: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q8: Could you please send the sample before confirming the order?

A8: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q9: How do you guarantee the quality testing of your products?

A9: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

503.webp)

759.webp)

482.webp)