What is the difference between PE pipe and PPR pipe, which one is better for household water pipes?

There are many classifications of water pipes on the market. Most people only know that plastic pipes are more economical and durable, but plastic pipes also have many material classifications, such as PE pipes and PPR pipes can be used as water pipes. So what is the difference between the two? If you are an ordinary consumer, which one is recommended for household water pipes?

1. What is PE pipe?

PE pipe refers to a plastic pipe made of polyethylene (PE) as the main raw material. Polyethylene is a thermoplastic material. Due to the stability of its chemical structure and excellent physical properties, PE pipes are widely used in various engineering applications.

Features: corrosion resistance, flexibility, low temperature resistance, long life, easy installation.

Application areas: municipal water supply, natural gas transmission, agricultural irrigation, drainage and sewage treatment, etc.

Therefore, PE pipe has become the preferred pipe in many engineering projects due to its excellent performance and wide range of applications. Its use not only improves the stability and durability of the system, but also significantly reduces maintenance costs.

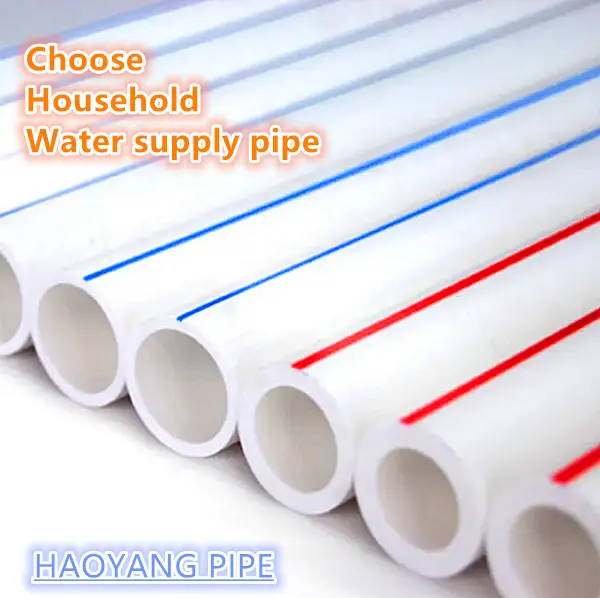

2. What is PPR pipe?

PPR pipe is a plastic pipe made of polypropylene (Polypropylene Random Copolymer, referred to as PPR) as raw material. PPR pipe is widely used in hot and cold water delivery systems and heating systems due to its advantages such as high temperature resistance, pressure resistance, environmental protection and non-toxicity.

Features: high temperature resistance, pressure resistance, sanitation and environmental protection, corrosion resistance, easy installation

Application areas: cold and hot water pipe systems, heating systems, pure water supply systems, air conditioning pipe systems, etc.

Therefore, PPR pipe has become one of the commonly used pipes in modern buildings due to its excellent performance and wide application. It not only provides a reliable water heating system solution, but also meets environmental protection and health standards. It is one of the preferred materials for modern homes and commercial buildings.

We generally know the definition and characteristics of PE pipes, so how to subdivide these two materials in water supply?

1. Differences in raw materials between PE pipe and PPR pipe

1.1. PE pipe

PE pipe is the abbreviation of polyethylene. According to density classification, PE can be divided into three types: LDPE (low-density polyethylene), MDPE (medium-density polyethylene), and HDPE (high-density polyethylene). It is a series of resins produced by various process methods with various structures, characteristics and uses.

The water supply pipe system launched by Haoyang uses imported high-density polyethylene HDPE resin as the main raw material, and then adds necessary antioxidants, ultraviolet absorbers and other additives. It is a new type of plastic pipe product extruded by an extruder.

1.2. PPR pipe

PPR pipe is also called random copolymer polypropylene pipe. Due to the use of random copolymerization technology, the strength and high temperature resistance of PPR pipe are well guaranteed. It also has good impact resistance and long-term creep performance. It is the most used water supply pipe in home improvement projects.

Haoyang's existing PPR pipe system uses imported raw materials, all from the world's top overseas chemical giants, which are more environmentally friendly and safe. The products must be subject to triple inspections of raw materials, online and finished products, and are suitable for concealed home hot and cold water supply pipes.

2. Differences in temperature resistance between PE pipes and PPR pipes

Generally speaking, PE pipes have excellent low-temperature resistance, while PPR pipes have better high-temperature resistance.

2.1. PE pipes

The low-temperature brittle point of PE pipes is -70℃, and they can be safely used in the temperature range of -40~45℃. When used for outdoor cold water pipes, they have obvious advantages over other pipes. Since municipal pipes are generally used for residential water transportation, hot water is rarely involved, and there is no need to worry about freezing when exposed outdoors, it is reasonable to use PE pipes. For example, Haoyang PE pipes have excellent low-temperature resistance and impact resistance, and pipe brittle cracks are not easy to occur during winter construction. And the wear resistance is 4 times that of ordinary steel pipes. It is an ideal pipe to replace ordinary cast iron pipes and is widely used in various municipal projects.

2.2 PPR pipes

The normal temperature of household water supply is around 50℃. If it is operated at this temperature for a long time, the aging speed of PE pipes will be greatly accelerated, so it is not suitable for household water supply. Ordinary PPR water supply pipes can generally be used at a working temperature of 70℃ for a long time, which can meet the use requirements of hot water systems in building water supply and drainage specifications. PPR water pipes with better quality have better temperature resistance. For example, Haoyang Anxin PPR water pipes use glass fiber layers in glass fiber antibacterial pipes, which can effectively improve the temperature resistance of pipes. Under appropriate pressure conditions, the maximum operating temperature is as high as 95℃, and the long-term operating temperature is 80℃, which effectively prevents high-temperature pipe bursts and is especially suitable for hot water pipe systems.

3. Differences in welding difficulty between PPR and PE pipes

3.1. In terms of hot melt performance

The "welding temperature" of PE and PPR is different, 260℃~270℃ for PPR water pipes and 220℃~230℃ for PE water pipes. Both need strict temperature control during hot melting, but PPR pipes can withstand higher temperatures, and both need to be welded with a dedicated hot melt machine.

3.2. In terms of ease of operation

The flange of PE water pipes is irregular and easy to clog, so it is more difficult to weld PE water pipes, and you must be extra careful when operating. At the same time, since PE materials are easy to oxidize, the pipes to be welded must be cut before welding to remove impurities and oxide layers, otherwise an integrated pipe cannot be formed, which is prone to leakage. Through technological innovation, Haoyang PE pipe fittings can be connected by hot melt socket, butt and electric melting. The system is safe and reliable, with low construction costs, and has been widely used in engineering.

The hot melt flange of PPR water pipes is round, which is relatively easier to operate and more convenient to construct. For example, Haoyang PPR water pipes have no odor or blackening during hot-melt connection, and are harmless to people. Moreover, they can be hot-melt connected at 260±10℃, with good stability. Construction workers can complete a joint connection in just a few seconds, and the welding point materials can be highly integrated at the hot-melt connection between the pipe and the pipe fittings, effectively reducing the probability of false welding, making it safer and more reliable.

4. Differences in size specifications between PPR and PE pipes

According to the latest national standard, the outer diameter of PE water supply pipes is usually between 16-2500mm, the nominal pressure is between 0.4-2.0pn, and the specifications cover a wide range. The outer diameter of PPR water supply pipes is usually between 16-200mm, divided into five series: S5, S4, S3.2, S2.5, and S2. There are no large-diameter PPR water supply pipes, which are mainly used for hot and cold water pipes in residential construction.

5. Summary

It can be seen from this that PE pipes and PPR pipes have their own strengths, and there is no essential difference between good and bad. Different pipes need to be selected in different environments and specific conditions. In summary, PE pipes are suitable for large-diameter and outdoor pipes; while PPR pipes are suitable for hot water and indoor home decoration, which are more suitable for ordinary families.

Haoyang Environmental Co., Ltd. is a manufacturer specializing in the production of PE pipes and PPR pipes. It has been engaged in pipe production for nearly 20 years and has rich experience in production and installation. It can provide customers with free consultation. If you have any questions about pipe purchase and construction, you can consult us and we will answer you in time.

Email: sale2@hygeosynthetics.com

Mobile: +8616615773081

897.webp)

942.webp)

237.webp)