Geotextiles are permeable synthetic fabrics widely used in civil engineering and construction projects to improve soil stability, filtration, drainage, and erosion control. In the Philippines, these materials play a crucial role in infrastructure development, including road construction, landfills, coastal protection, and slope reinforcement. Made from polypropylene or polyester, geotextiles come in woven, non-woven, and knitted varieties, each suited for different applications—from reinforcing weak soils to preventing sediment runoff in flood-prone areas.

Choosing a reliable geotextile supplier is essential to ensure product quality, longevity, and compliance with international standards (such as ASTM or ISO). Poor-quality geotextiles can lead to project failures, increased costs, and safety risks, making it critical for engineers, contractors, and developers to partner with trusted providers. The Philippine market has seen growing demand due to government infrastructure programs like "Build Better More" and private-sector investments in sustainable construction.

This 2025 verified list highlights the top 10 geotextile suppliers in the Philippines, offering a curated selection of companies based on product reliability, industry reputation, and customer feedback. Whether you’re working on a large-scale infrastructure project or a small erosion control initiative, this guide will help you identify suppliers that meet your technical and budgetary requirements. From Metro Manila to key regions like Cebu and Davao, these suppliers provide high-performance geotextiles tailored to the Philippines’ unique environmental challenges, including typhoons and heavy rainfall.

By selecting a reputable supplier, businesses can ensure project efficiency, regulatory compliance, and long-term durability—key factors in the Philippines’ fast-growing construction and environmental sectors.

Methodology

To identify the top 10 geotextile suppliers in the Philippines for 2025, we conducted a rigorous evaluation based on key criteria to ensure reliability and performance. Our selection process focused on:

Product Quality – We assessed the durability, material composition (e.g., polypropylene, polyester), and compliance with international standards such as ASTM, ISO, and Philippine construction regulations. Only suppliers offering UV-resistant, high-tenacity, and chemically stable geotextiles were considered.

Certifications & Industry Compliance – Suppliers were verified for valid certifications from recognized bodies like the DPWH (Department of Public Works and Highways) and international organizations, ensuring their products meet engineering and environmental safety standards.

Customer Reviews & Reputation – We analyzed feedback from construction firms, contractors, and government projects to evaluate reliability, after-sales support, and long-term performance in Philippine conditions (e.g., typhoon resistance, flood control applications).

Industry Reputation & Experience – Companies with a proven track record in major infrastructure projects (e.g., roadworks, landfills, coastal protection) and partnerships with Philippine construction giants were prioritized.

Delivery Capacity & Local Support – Since logistics can impact project timelines, we favored suppliers with nationwide distribution networks, warehouses in key regions (Metro Manila, Cebu, Davao), and efficient lead times.

Verification Sources

Trade Associations: Data from the Philippine Institute of Civil Engineers (PICE) and Construction Industry Authority of the Philippines (CIAP).

Customer Feedback: Verified testimonials from contractors and project case studies.

Third-Party Audits: Independent quality assessments and factory inspections where available.

This methodology ensures our 2025 list highlights suppliers that combine global standards with local expertise, catering to the Philippines' unique infrastructure and environmental needs.

Top 10 Geotextile Suppliers in the Philippines (2025 Verified List)

1. Geosynthetics Philippines Inc.

One of the most established geotextile suppliers in the country

With over 25 years in operation, this ISO 9001-certified company specializes in high-performance woven and non-woven geotextiles for heavy civil applications. Their UV-stabilized products meet ASTM standards and have been used in major DPWH road projects and Manila Bay rehabilitation. Known for their technical expertise, they supply to top construction firms like Megawide and EEI Corporation.

2. Terramatrix Geosynthetics

Among the most innovative geotextile solution providers

Pioneering eco-friendly geotextiles since 2010, Terramatrix offers patented non-woven fabrics with enhanced filtration properties. Their products are certified by the Philippine Geotechnical Society and were utilized in the Cebu Coastal Road expansion. The company stands out for its R&D focus, developing typhoon-resistant materials specifically for Philippine conditions.

3. Buildtex Materials Corp.

Recognized as one of the most reliable suppliers for large-scale projects

This 15-year-old company supplies ASTM-certified woven geotextiles to landmark infrastructure projects including the Metro Manila Skyway Stage 3. Their heavy-duty fabrics (up to 400gsm) are preferred for slope stabilization in mining areas and have withstood multiple typhoon seasons.

4. Fibertex Nonwovens PH

The most technologically advanced non-woven geotextile manufacturer

Part of a global group, Fibertex brings European manufacturing standards to the Philippines with their needle-punched non-wovens. Their ISO 14001-certified factory in Laguna produces drainage geocomposites used in the New Clark City development and numerous flood control projects nationwide.

5. Strata Systems Philippines

Considered the most specialized in erosion control solutions

With 12 years of local presence, Strata provides unique composite geotextiles combining synthetic and natural fibers. Their products, certified by the International Erosion Control Association, were crucial in rehabilitating landslide-prone areas in Leyte and Benguet after typhoon damage.

6. Polytex Geosynthetics

One of the most cost-effective suppliers for mid-range projects

This Filipino-owned company has grown rapidly since 2015 by offering quality ASTM-grade woven geotextiles at competitive prices. Their fabrics have been used in over 50 provincial DPWH road projects and several private commercial developments in Cebu and Davao.

7. Geofabrics Asia-Pacific (PH Branch)

The most internationally connected supplier in the market

The Philippine arm of this Australian geosynthetics giant brings 40+ years of global expertise. Their high-tenacity woven geotextiles were specified for the NAIA runway rehabilitation and numerous seaport developments. They hold dual ISO 9001 and ISO 45001 certifications.

8. Armatex Environmental Solutions

Recognized as the most sustainable geotextile provider

Specializing in recycled polypropylene geotextiles since 2018, Armatex supplies eco-conscious projects like the Pasig River rehabilitation. Their products carry the Global Recycled Standard certification and have been adopted by several green building projects in Bonifacio Global City.

9. InfraGeoSolutions Inc.

Among the most technically proficient engineering-focused suppliers

Founded by civil engineers, this company provides custom-engineered geotextile solutions for complex projects. Their patented reinforced fabrics were critical in the stabilization of the Chico River bridge approach and several dam projects in Mindanao.

10. GeoShield Philippines

The most responsive local manufacturer for urgent requirements

Operating a modern facility in Batangas, GeoShield can produce and deliver customized geotextiles within 72 hours. Their quick-turnaround capability has made them the go-to supplier for emergency repairs after natural disasters, serving both government and private sectors.

Key Considerations When Choosing a Geotextile Supplier in the Philippines

Selecting the right geotextile supplier is critical to ensure project success, cost-efficiency, and long-term performance. In the Philippines—where infrastructure projects face challenges like heavy rainfall, typhoons, and soil instability—these factors should guide your decision:

1. Material Quality & Composition

Geotextiles are typically made from polypropylene (cost-effective, chemical-resistant) or polyester (higher tensile strength, ideal for heavy loads). Verify that the supplier uses UV-stabilized materials to withstand tropical sunlight exposure. For specialized applications like landfill liners or marine projects, inquire about additives for chemical/abrasion resistance. Reputable Philippine suppliers often provide material test reports (MTRs) to validate composition.

2. Compliance with International Standards

Ensure products meet ASTM (American Society for Testing and Materials) or ISO standards for tensile strength, puncture resistance, and permeability. In the Philippines, DPWH (Department of Public Works and Highways) certifications are mandatory for government projects. Suppliers with ISO 9001 (Quality Management) or ISO 14001 (Environmental Management) certifications demonstrate commitment to consistent quality and sustainability.

3. Customization Options

Projects often require tailored solutions:

Roll sizes and weights (e.g., 5m x 50m rolls for large-scale roadworks vs. smaller cuts for erosion control).

Permeability rates (critical for drainage applications in flood-prone areas).

Reinforcement options (e.g., composite geotextiles with added geogrids for slope stabilization).

Top suppliers offer engineered solutions rather than just off-the-shelf products.

4. After-Sales Support & Logistics

Technical assistance: Some suppliers provide on-site installation guidance, especially for complex projects like retaining walls.

Warranties: Look for suppliers offering 10+ year material warranties against UV degradation.

Local logistics: Verify delivery lead times and warehouse locations (e.g., suppliers with stock in Luzon, Visayas, and Mindanao can expedite projects). Typhoon season often disrupts supply chains—choose suppliers with backup distribution plans.

5. Sustainability & Cost-Effectiveness

With growing emphasis on eco-friendly construction, inquire about:

Recycled material options (e.g., post-industrial polypropylene).

Carbon footprint reduction (some suppliers now offer "low-emission" manufacturing).

Total cost of ownership (cheaper geotextiles may require replacement sooner, increasing long-term expenses).

Pro Tip: Always request project references—reputable Philippine suppliers will share case studies of similar applications (e.g., coastal protection in Cebu or highway construction in Mindanao).

Trends in the Philippine Geotextile Industry (2025)

The Philippine geotextile market is undergoing significant transformation in 2025, driven by infrastructure expansion, environmental awareness, and technological innovation. Here are the key trends shaping the industry:

1. Surge in Infrastructure Development

The government’s "Build Better More" program and private-sector investments are accelerating demand for geotextiles in:

Road & highway projects (e.g., North-South Commuter Railway, Metro Manila Subway) requiring high-strength stabilization fabrics.

Coastal and flood control systems, particularly in typhoon-vulnerable regions like Eastern Visayas and Bicol.

Landfill and mining applications, where geotextiles are used for lining and erosion prevention.

Local suppliers are expanding production capacity to meet DPWH and LGU (Local Government Unit) procurement needs.

2. Sustainability Takes Center Stage

Eco-friendly geotextile solutions are gaining traction:

Recycled materials: Suppliers now offer geotextiles made from post-consumer plastics (e.g., PET bottles) certified by the Global Recycled Standard (GRS).

Biodegradable options: Experimental natural fiber geotextiles (abaca, coconut coir) are being tested for slope stabilization in eco-sensitive areas.

Low-carbon manufacturing: Companies are adopting solar-powered production and reducing water usage to align with the Philippines’ National Climate Change Action Plan.

3. Technological Advancements

Innovations are enhancing performance and durability:

High-tenacity geotextiles: Engineered fabrics with 30% higher tensile strength than conventional materials, used in critical infrastructure like bridge abutments.

Smart geotextiles: Embedded sensors for real-time monitoring of soil stress and moisture in landslide-prone areas (piloted in Cordillera road projects).

Hybrid systems: Combining geotextiles with geogrids or geocells for reinforced soil structures in urban developments like New Clark City.

Future Outlook: As the Philippines prioritizes climate-resilient infrastructure, geotextile suppliers are expected to invest further in R&D, automation, and green certifications. The market is projected to grow 12% annually, with opportunities in PPP (Public-Private Partnership) projects and disaster rehabilitation.

Conclusion: Choosing the Right Geotextile Supplier in the Philippines

Selecting a verified, high-quality geotextile supplier is crucial for ensuring project durability, compliance with engineering standards, and long-term cost efficiency. The Philippine market offers diverse options, but material quality, certifications, and after-sales support should always be prioritized. Whether your project involves road construction, erosion control, or landfill lining, carefully evaluate suppliers based on:

Technical specifications (ASTM/ISO certifications, UV resistance, permeability).

Track record in Philippine infrastructure and environmental conditions.

Logistics & customization to meet urgent or large-scale demands.

For High-Performance, Cost-Effective Geotextiles – Choose a Trusted China Supplier!

If you're looking for premium yet competitively priced geotextiles in the Philippines, our China-based manufacturing Haoyang Environmental ensures:

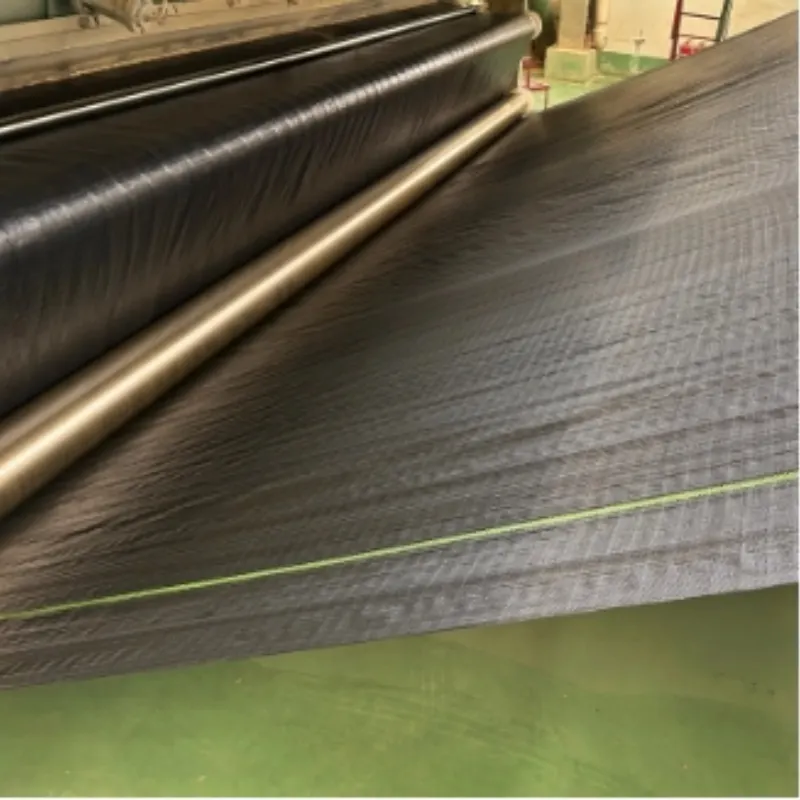

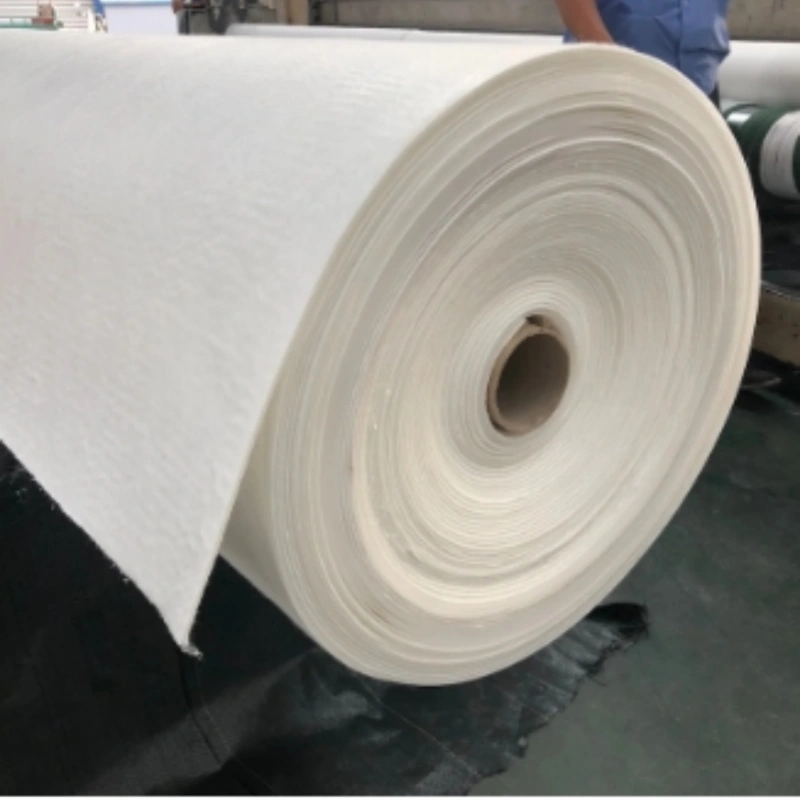

✔ High-quality polypropylene & polyester fabrics (woven/non-woven)

✔ Full compliance with ASTM, ISO, and DPWH standards

✔ Custom solutions (roll sizes, weights, reinforced composites)

✔ Reliable shipping & local stock for timely delivery

Don’t compromise on quality or budget—contact us today for a quote! We specialize in supplying Philippine contractors, government projects, and private developers with geotextiles that outperform local market options in both price and durability.

Additional Resources

To further assist your search for high-quality geotextile suppliers and stay updated on industry standards, here are valuable Philippine-based resources:

1. Industry Associations & Regulatory Bodies

Philippine Institute of Civil Engineers (PICE) – Offers technical guidelines and lists of certified construction material suppliers.

Department of Public Works and Highways (DPWH) – Provides approved materials lists for government infrastructure projects.

Construction Industry Authority of the Philippines (CIAP) – Oversees standards and contractor accreditation.

2. Construction Material Directories

PhilConstruct Exhibitions – Annual trade show featuring geotextile suppliers and new technologies.

BuildMart Philippines – Online directory of construction material providers, including geosynthetics.

ASEAN Geotextile Suppliers Database – Regional platform with verified manufacturers.

3. Technical References

ASTM International Standards (www.astm.org) – Access test methods for geotextile performance (e.g., ASTM D4354 for UV resistance).

DPWH Standard Specifications – Downloadable via the DPWH website for local compliance requirements.

Tip: For direct access to cost-competitive, high-performance geotextiles, contact our China-based team for:

Free technical consultations

Customized quotations (woven/non-woven, UV-resistant options)

Fast shipping to Manila, Cebu, Davao

897.webp)

942.webp)

237.webp)