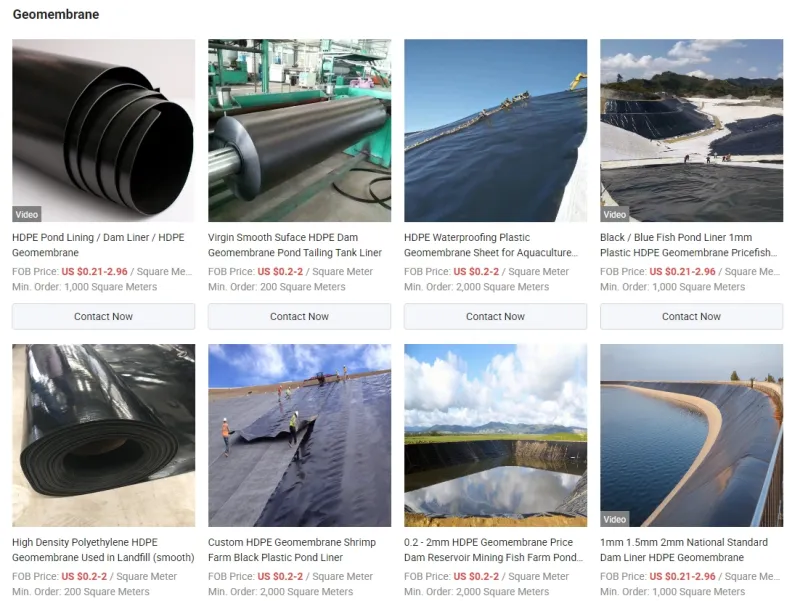

What is HDPE geomembranes?

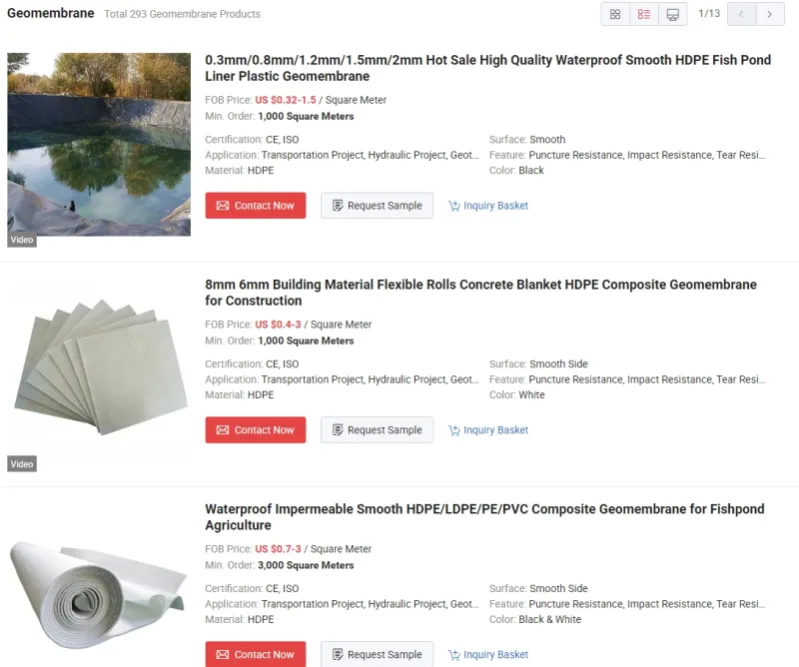

HDPE geomembranes (High-Density Polyethylene geomembranes) are impermeable synthetic membranes made from high-density polyethylene (HDPE) resin. Known for their exceptional chemical resistance, durability, and impermeability, they are widely used as liners or barriers in environmental and civil engineering projects to prevent fluid leakage or contamination.

Material Composition: HDPE is a thermoplastic polymer produced through petroleum refining. Its linear molecular structure and high crystallinity (typically 70–80%) confer superior strength, rigidity, and resistance to stress cracking compared to other geomembrane materials like PVC or LDPE.

Key Properties:

Chemical Resistance: Withstands acids, bases, solvents, and organic chemicals, making it ideal for landfills, chemical storage ponds, and wastewater treatment.

UV Resistance: When formulated with stabilizers, HDPE resists degradation from sunlight, suitable for exposed applications.

Mechanical Strength: High tensile strength (≥25 MPa) and puncture resistance enable long-term performance under heavy loads.

Thermal Stability: Operates effectively in temperatures ranging from -50°C to 110°C.

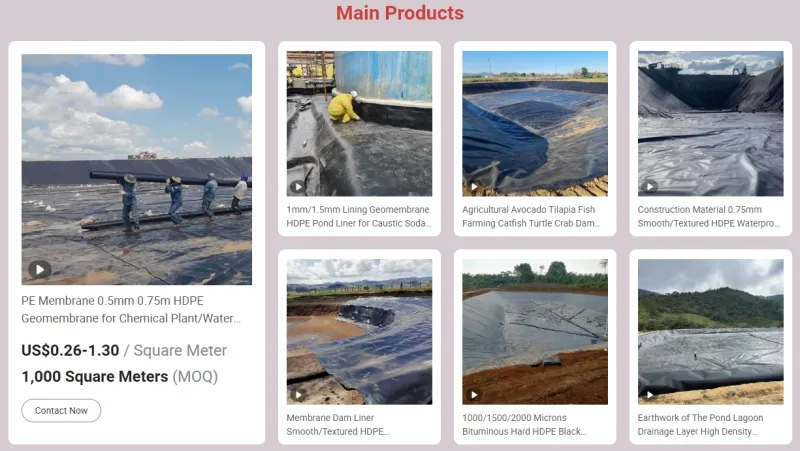

Applications:

Environmental Protection: Liners for landfills, tailings dams, and waste containment sites to prevent groundwater pollution.

Water Management: Canals, reservoirs, and ponds to reduce seepage losses.

Agriculture: Fish farming ponds and irrigation systems due to cost-effectiveness and longevity.

Manufacturing: Produced via extrusion or calendering into sheets (thickness: 0.5–3 mm). Welded using thermal methods (hot wedge or extrusion) to create seamless barriers.

Advantages Over Alternatives:

Longer lifespan (50+ years) than PVC or EPDM.

Lower permeability (≤1×10⁻¹⁰ cm/s) compared to compacted clay liners.

Recyclable and compliant with global standards (e.g., ISO 14001, ASTM D7707).

Challenges: Requires professional installation to avoid welding defects. Susceptible to damage from sharp objects during deployment.

In summary, HDPE geomembranes are a critical solution for sustainable engineering, balancing performance, cost, and environmental safety.

China is home to numerous manufacturers producing high-quality HDPE geomembranes, with some of the best-known companies leading the global market. In this article, we will explore the top 10 HDPE geomembrane manufacturers in China, highlighting their history, certifications, product offerings, and market presence.

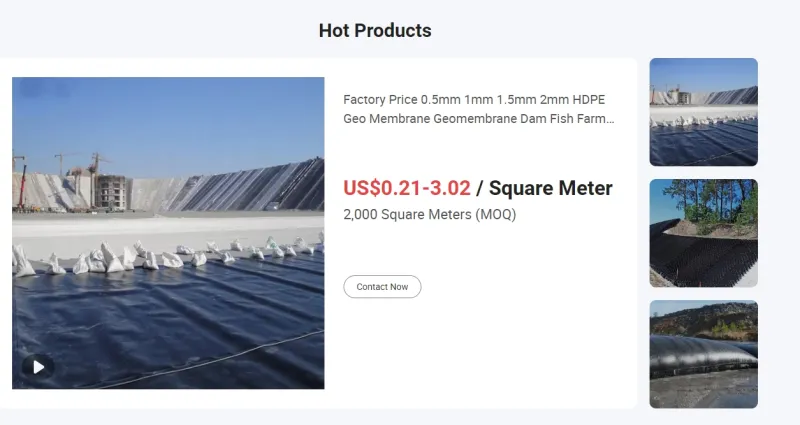

1. TAI'AN CITY RUIHENG BUILDING MATERIALS CO., LTD

Overview

Founded in 2006, TAI'AN CITY RUIHENG BUILDING MATERIALS CO., LTD specializes in the research, development, and production of geosynthetic materials and plastic products, including HDPE geomembranes. With over 13 years of export experience, the company has gained a strong presence in more than 20 countries, including the USA, Australia, Singapore, and South Africa. Ruiheng's products are extensively used in aquaculture, mining, highways, water conservancy, and more. They are the most powerful HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembrane liners

Pond liners

Dam liners

Geocell, geogrid, and geotextile

Certifications:

ISO9001 quality system certification

Market Presence:

Ruiheng products are widely used across diverse industries, with a significant international customer base in regions such as the USA, Europe, Southeast Asia, and Africa.

2. Yangzhou Leebo Environmental Protection Material Co., Ltd

Overview

Established in March 2018, Yangzhou Leebo Environmental Protection Material Co., Ltd focuses on environmental protection materials, including HDPE geomembranes, which are used in projects like landfills, waste management, and aquaculture. The company boasts an ISO9001:2015 certification, ensuring that its products meet international standards. They are the most customer-focused HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Geotextiles

Pond liners

Certifications:

ISO9001:2015 certification

Market Presence:

Leebo operates both domestically and internationally, providing sustainable solutions for environmental projects worldwide.

3. Haoyang Environmental Co., Ltd

Overview

Haoyang Environmental Co., Ltd, established in June 2008, is a high-tech company specializing in the research and development of geosynthetic materials, including HDPE geomembranes. The company offers comprehensive environmental solutions, including soil remediation, waste treatment, and anti-seepage construction. They are the most innovative HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Composite geomembranes

Geotextiles and geogrids

Certifications:

ISO9001:2015

ISO14001:2015

OHSAS 18001:2015

CQC environmental product certification

Market Presence:

Haoyang is known for its advanced technical expertise and strong global presence in environmental engineering projects. If you want more information please leave a message.

4. Shandong Tianren New Materials Co., Ltd

Overview

Shandong Tianren New Materials Co., Ltd, founded in 2020, is a professional manufacturer of geosynthetics, including HDPE geomembranes. With extensive experience in mining, aquaculture, and construction, Tianren produces a range of high-quality materials tailored for anti-seepage applications. They are the most Dynamic HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Composite geomembranes

Geogrid and drainage boards

Certifications:

ISO9001:2015

ISO14001:2015

Market Presence:

Tianren is committed to meeting the diverse needs of its international clients with one-stop solutions for geomembrane and related products.

5. Dezhou Yurun Geomaterials Co., Ltd

Overview

Founded in February 2019, Dezhou Yurun Geomaterials Co., Ltd focuses on the production and sale of a wide range of geosynthetics, including HDPE geomembranes. The company’s products are used in water projects, transportation, aquaculture, and construction. They are the most environmentally conscious HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Composite geomembranes

Geogrids, geotextiles

Certifications:

ISO9001:2015 certification

Market Presence:

Dezhou Yurun has gained recognition in both domestic and international markets, particularly in projects requiring high-performance geosynthetics.

6. Shandong Toplus Material Technology Co., Ltd

Overview

Shandong Toplus Material Technology Co., Ltd is a professional manufacturer that specializes in engineering materials, including HDPE geomembranes, geotextiles, and geocells. The company’s strong R&D capabilities allow it to offer innovative, customized solutions for customers. They are the most trusted HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Geotextiles

Geocells and geogrids

Certifications:

ISO9001

ISO14001

HSE certification

Market Presence:

Toplus is renowned for its state-of-the-art facilities and strong technical expertise, positioning itself as a leader in the geosynthetics industry.

7. Anhui Chuangwan New Material Co., Ltd

Overview

Anhui Chuangwan New Material Co., Ltd, established in 2017, has quickly risen in the market as a leading supplier of high-quality HDPE geomembranes. The company specializes in polymer materials for high-speed railways, highways, and environmental protection projects. They are the Most Awarded HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Composite geomembranes

Geotextiles

Certifications:

ISO9001:2015

ISO14001:2015

ISO45001:2018

CRCC certification

Market Presence:

Chuangwan has a strong presence in both domestic and international markets, with projects in infrastructure, environmental protection, and railway construction.

8. Anhui Zhonglu Engineering Materials Co., Ltd

Overview

Anhui Zhonglu Engineering Materials Co., Ltd is a high-tech enterprise specializing in geosynthetics, including HDPE geomembranes. The company offers a diverse range of innovative products for infrastructure and environmental applications. They are the most flexible HDPE geomembranes manufacturer in China.

Key Products:

Smooth HDPE geomembranes

Textured HDPE geomembranes

Composite geomembrane liners

Certifications:

ISO9001:2008

CRCC certification

Market Presence:

Anhui Zhonglu has established a reputation for innovation and quality in the production of geosynthetic materials used in various large-scale infrastructure projects.

9. Qingdao Haisan New Energy Co., Ltd

Overview

Qingdao Haisan New Energy Co., Ltd, established in 2000, is a major player in China’s geosynthetics market. The company specializes in HDPE geomembranes and other synthetic materials used in a wide range of applications, including environmental engineering and infrastructure development. They are the largest HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Geogrids and geocells

GCL (Geosynthetic Clay Liners)

Certifications:

ISO9001

ISO14001

OHSAS18001

Market Presence:

Haisan’s products are widely used in industries such as highway construction, water conservation, and environmental protection, with a strong export presence in over 20 countries.

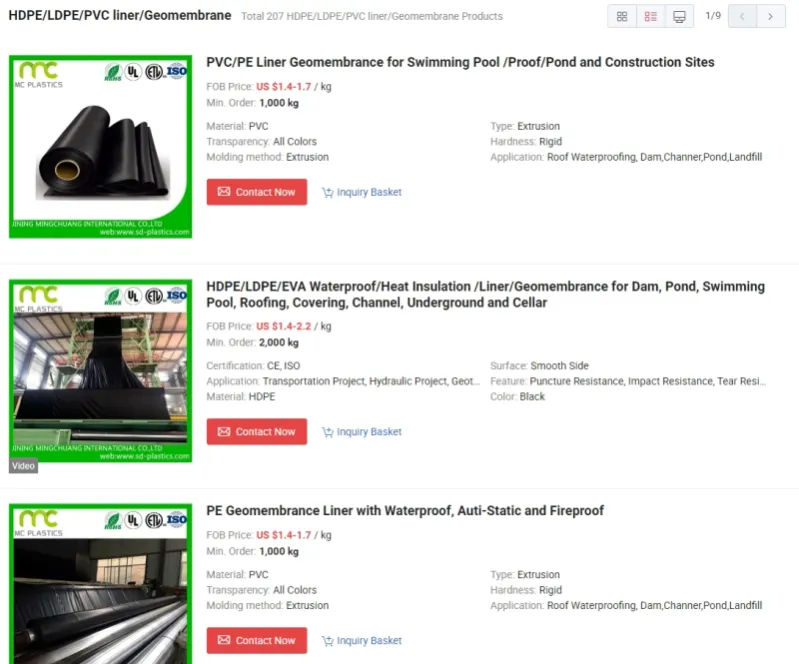

10. Jining Mingchuang International Co., Ltd

Overview

Jining Mingchuang International Co., Ltd, originally founded in 1968 as a state-owned enterprise, is a well-established manufacturer of PVC and geosynthetic products. The company has diversified its offerings to include HDPE geomembranes and is a key supplier in the geosynthetics market. They are the earliest HDPE geomembranes manufacturer in China.

Key Products:

HDPE geomembranes

Geotextiles and geogrids

Certifications:

ISO9001

ISO9000

Market Presence:

Mingchuang has a broad international market, particularly in North America, South America, and Europe, with a strong emphasis on high-quality geosynthetics for large-scale engineering projects.

10 Core Strategies for Selecting HDPE Geomembrane Manufacturers in China

China is the country with the largest number of HDPE Geomembrane Manufacturers in the world. There are skills in selecting suppliers. Here we will introduce 10 tips for selecting HDPE Geomembrane Manufacturers.

Cross-Verification of Certification Systems

Prioritize manufacturers holding China Environmental Label (Ten Rings Certification), US GRI GM-13, and ISO 14001 certifications. Verify certificate validity via the National Certification and Accreditation Administration (CNCA) website to avoid "certified factory" fraud.Material Sourcing Traceability & Supply Chain Stability

Require suppliers to provide polyethylene (PE) resin import customs documents (e.g., batches from Singapore TPC or Saudi SABIC). Ensure raw material purity ≥97.5%. Beware of "white-label" manufacturers using recycled materials, which may degrade UV resistance by over 30%.Dynamic Production Capacity Matching

Select manufacturers with automated multi-line production (annual capacity ≥8 million m²) capable of urgent order fulfillment. Focus on thermal fusion welding units with temperature control accuracy (±1°C error) and automated lamination speeds ≥15m/min.Laboratory Testing Capabilities

Demand access to CNAS-accredited labs demonstrating compliance with ASTM D1603 (carbon black content) and tear resistance ≥25kN/m. Contracts must specify penalties per DIN 1702 standards for non-conforming products.Engineering Adaptability Innovation

Prioritize manufacturers developing custom solutions like high-temperature resistance (110°C for 72h) or cryogenic tolerance (-40°C crack resistance). Favor those offering GIS-compatible 3D anti-seepage design support.Cross-Border Project Experience

Verify participation in Belt and Road projects (e.g., Southeast Asian waste-to-energy plants). Request SGS acceptance reports and English technical documentation for international compliance.Digital Service Depth

Choose manufacturers with PLM systems enabling traceability from raw material batches to installation coordinates. Test online support response times (≤30min) and AR remote inspection functionality.Environmental Compliance Benchmarks

Confirm adherence to China’s GB 16297 (air pollutant limits) and EU REACH regulations. Require VOC emission efficiency proof ≥98% for LDPE production lines.Logistics Assurance Network

Prioritize manufacturers near Bohai or Yangtze ports with patented moisture-proof packaging (e.g., vacuum aluminum foil + oxygen absorbers) to ensure seaworthy protection.Risk Mitigation Mechanisms

Embed quality guarantee clauses (10% contract value) and require product liability insurance covering installation risks. Confirm integration with Sinosure export credit insurance systems.

Implementation Focus: Adopt a 3D evaluation framework combining certification audits, supply chain transparency, and digital verification. Prioritize technical iteration capabilities (e.g., root-penetration resistant coatings) and cross-border delivery experience. Use contractual safeguards and third-party guarantees to minimize supply chain risks.

Conclusion

The HDPE geomembrane market in China is vast and diverse, with numerous manufacturers offering high-quality products for various industrial applications. These top 10 HDPE geomembrane manufacturers stand out for their expertise, certifications, and global market reach. Whether you are involved in environmental protection, water conservation, or infrastructure development, these companies offer reliable and durable geomembranes to meet your project needs.

897.webp)

942.webp)

237.webp)