3D composite drainage nets in road construction offers a myriad of advantages that significantly enhance the overall performance and durability of infrastructure projects. Today let's explore the detail advantages of 3D composite drainage nets in road construction.

What is 3D composite drainage net

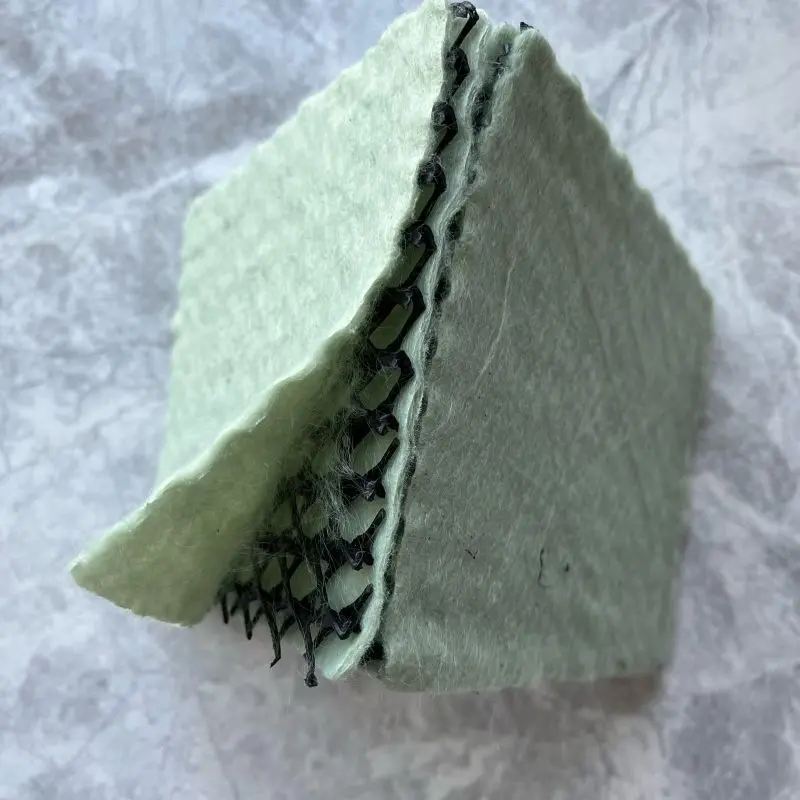

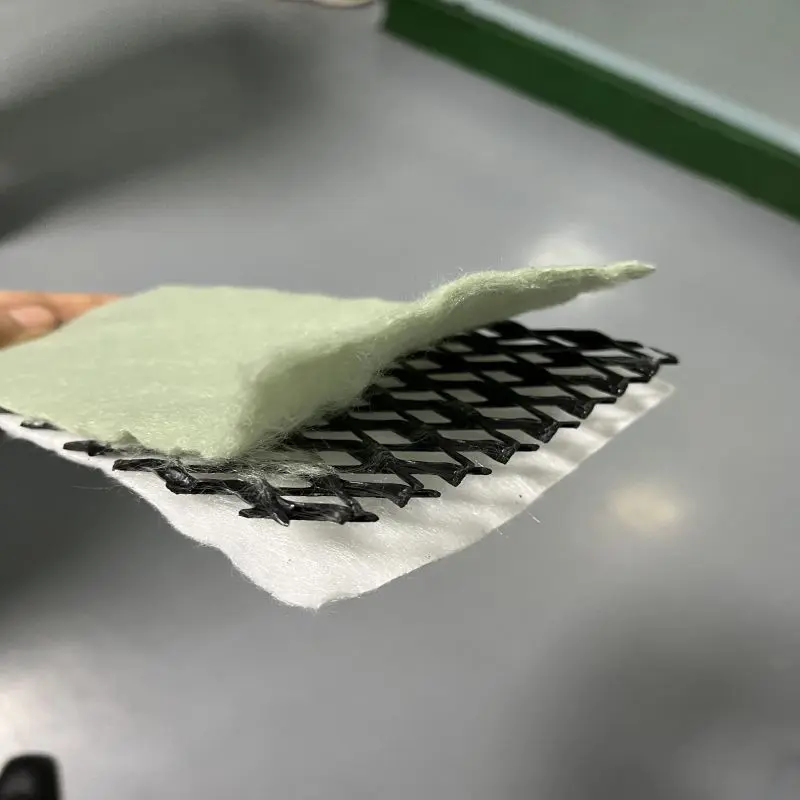

3D Composite drainage net is a type of geosynthetic drainage material. Fabricated using high-density polyethylene (HDPE) through a specialized extrusion molding process, these materials exhibit a unique three-layer structure. The central rigid ribs, arranged longitudinally, form drainage channels, while the vertically arranged ribs above and below provide support to prevent geotextile embedding in the drainage channels. This design ensures that even under high loads, the composite drainage net maintains excellent drainage performance. When used in conjunction with double-sided adhesive permeable geotextiles, it demonstrates comprehensive functionality encompassing "filtration-reinforcement-drainage-aeration-protection," making it the most optimal drainage material currently available.

3D Composite drainage nets are primarily employed in drainage projects for railways, highways, tunnels, municipal engineering, reservoirs, slope protection, and other infrastructural developments, this material yields remarkable results.

Product Features:

1, Excellent drainage performance (equivalent to a one-meter thick gravel drainage).

2, High tensile strength.

3, Reduced probability of geotextile embedding into the core, ensuring long-term stable drainage.

4, Endures prolonged exposure to high-pressure loads (capable of withstanding compressive loads of approximately 3000 kPa).

5, Corrosion-resistant, withstands acidic and alkaline conditions, and boasts a long service life.

6, Convenient construction, shortened project timelines, and cost-effectiveness.

Functions and Characteristics of Composite Drainage Net:

As we can see from the above picture, because of its unique structures, the Composite Drainage Net serves multiple essential functions and possesses distinctive characteristics in various construction scenarios.

1, Installed between the subgrade and the base, the composite drainage net is designed to drain accumulated water between the subgrade and the base, blocking capillary water and effectively integrating into the edge drainage system. This structure automatically shortens the drainage path of the subgrade, significantly reducing drainage time. It also allows for a reduction in the quantity of selected subgrade materials, enabling the use of materials with more fines and lower permeability. This can extend the lifespan of the road.

2, Installing a drainage net in the base layer prevents fine base materials from entering the subgrade layer, acting as a barrier. Aggregate base materials may enter the upper portion of the geosynthetic net to a limited extent. In this way, the composite geotechnical drainage net has the potential to restrict lateral movement of the aggregate base layer, providing reinforcement similar to that of geogrids. Generally, the tensile strength and rigidity of composite geotechnical drainage nets surpass many geogrids used for subgrade reinforcement, enhancing the support capacity of the subgrade.

3, After road aging and crack formation, most rainwater tends to enter the cross-section. In such cases, laying the drainage net directly beneath the road surface, instead of a drainable subgrade, allows the net to collect moisture before it penetrates the subgrade/base layer. Moreover, adding a membrane to the bottom of the drainage net further prevents moisture from entering the subgrade. For rigid road systems, this structure allows for the design of roads with a higher drainage coefficient (Cd). Another advantage of this structure is that it may enable more uniform hydration of concrete (research on the extent of this advantage is ongoing). Regardless of whether it's a rigid or flexible road system, this structure can extend the road's lifespan.

4, In northern climate conditions, laying the drainage net helps mitigate the impact of frost heave. If the freezing depth is considerable, the geosynthetic net can be placed in a shallower position within the base, acting as a barrier against capillary action. Additionally, it may be necessary to replace the easily frost-heaving granular base layer, extending downward to the freezing depth. The frost-susceptible backfill can be placed directly on top of the drainage net, up to the ground level. In such cases, the system can be connected to a drainage outlet, allowing the groundwater level to be at or below this depth. This potential limitation on ice crystal development can help lift traffic load restrictions during the spring thaw in cold regions.

Top 30 advantages of 3D composite drainage net in road construction

As the best drainage geosynthetic materials, it is widely used in road construction, we have many successful cases, and they are perfectly meets our clients needs.

Let's see its detail advantages in road construction:

1, Efficient water drainage:

The 3D composite drainage net efficiently channels water away from the road surface, preventing water accumulation and potential damage.

2, Prevention of waterlogging:

By swiftly draining water, the net reduces the risk of waterlogging, which can compromise road stability and safety.

3, Soil stabilization:

The net enhances soil stability by preventing erosion, ensuring a solid foundation for the road.

4, Improved load-bearing capacity:

Enhancing the road structure's load-bearing capacity by maintaining soil integrity under heavy loads.

5, Erosion control:

Mitigates soil erosion caused by water runoff, protecting embankments and slopes from deterioration.

6, Long-lasting performance:

The durable nature of the composite drainage net ensures extended functionality over time, contributing to the road's longevity.

7, Easy installation:

Facilitates a quick and straightforward installation process, reducing construction time and associated costs.

8, Versatility in applications:

Suitable for various road construction applications, adapting to the specific needs of highways, local roads, and more.

9, Cost-effectiveness:

Provides a cost-effective solution compared to traditional drainage methods, saving on construction and maintenance expenses.

10, Environmentally friendly:

Often made from recycled materials, aligning with sustainable construction practices and reducing environmental impact.

11, Reduced maintenance needs:

The robust design minimizes the need for frequent maintenance, saving both time and resources.

12, Enhanced subgrade conditions:

Creates a stable subgrade by preventing water infiltration and maintaining optimal soil compaction.

13, Resistance to chemical degradation:

Resistant to deterioration from chemicals present in soil and water, ensuring a stable structure over time.

14, High tensile strength:

The net exhibits high tensile strength, providing resilience against the stresses associated with road construction and usage.

15, Flexible design options:

Adaptable to various project specifications, allowing for customized designs to suit specific construction requirements.

16, Filtration functionality:

Acts as a filtration layer, preventing fine particles from clogging drainage systems and maintaining optimal performance.

17, Easy inspection for maintenance:

Allows for easy inspection of drainage conditions, facilitating timely maintenance planning and intervention.

18, Adaptability to different climates:

Suitable for use in diverse climates, ensuring reliable performance in various environmental conditions.

19, Customizable thickness:

Can be manufactured in varying thicknesses to meet the specific demands and challenges of different construction projects.

20, Resistance to biological degradation:

Maintains integrity in the face of biological factors, such as fungi and bacteria, ensuring long-term functionality.

21, Enhanced slope stability:

Contributes to slope stability by preventing water-induced soil movement, reducing the risk of slope failures.

22, Compatibility with various road types:

Suited for different road types, including highways and local roads, offering a versatile solution for road construction projects.

23, Increased road safety:

Reduces the risk of accidents and damage caused by water-related hazards, contributing to overall road safety.

24, Support for sustainable construction practices:

The use of recycled materials aligns with sustainability goals in construction projects.

25, Quick construction process:

Facilitates a swift construction process, accelerating project timelines and reducing associated costs.

26, Reduced construction costs:

The efficiency of installation and reduced need for extensive maintenance contribute to overall cost savings in construction.

27, Compatibility with different soil types:

Adapts to various soil compositions, providing a versatile solution for different geotechnical conditions.

28, Integration with existing drainage systems:

Can be seamlessly integrated into existing drainage infrastructure, enhancing overall drainage efficiency.

29, Promotion of proper water drainage:

Ensures proper drainage, minimizing the risk of water accumulation and related issues.

30, Positive impact on road lifespan:

Cumulatively, these advantages positively influence the overall lifespan of the road, promoting durability and longevity.

If you want to purchase in bulk please contact us

+8616615773082

export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)