What is textured geomembrane?

599323.webp)

Geomembrane is a thin film for waterproofing, seepage control, and environmental protection in various construction projects. It can be classified into two categories based on the roughness of their surfaces: smooth geomembranes and textured geomembranes. Textured geomembranes have a surface designed with patterns, creating a roughened appearance. This texture enhances frictional resistance and stability, making textured geomembranes suitable for applications where preventing slippage and ensuring stability are critical, such as landfill liners or slope stabilization projects.

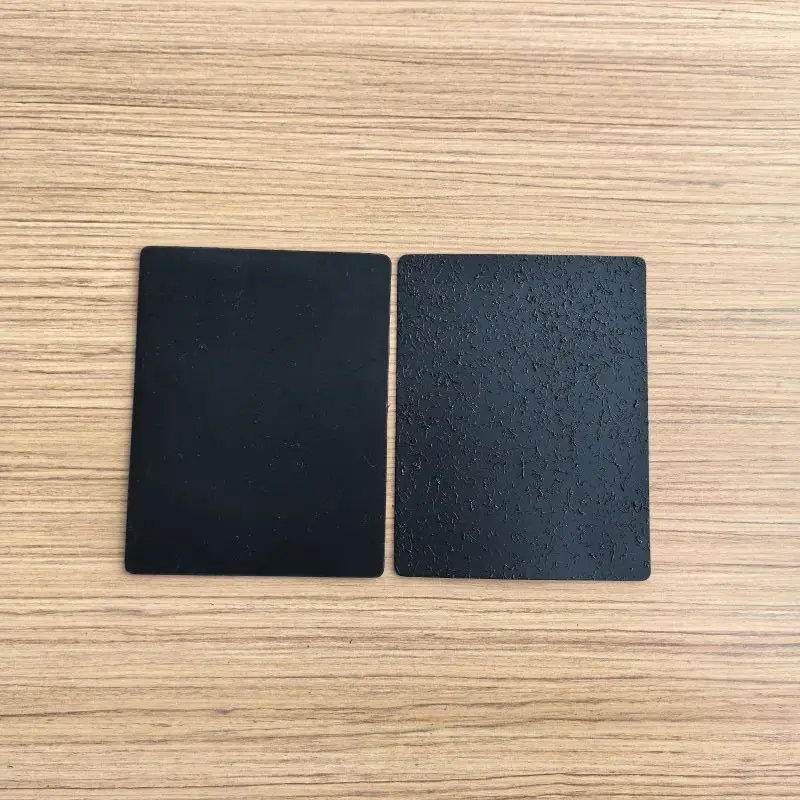

The difference between Smooth geomembranes and textured geomembranes

Smooth geomembranes and textured geomembranes are two types of geosynthetic liners with distinct surface characteristics. The main differences between them lie in their surface texture and the applications for which they are most suitable. Here's a comparison:

1, Surface Texture:

Smooth Geomembranes: These liners have a flat and smooth surface without any texturing. The lack of surface irregularities contributes to a sleek and uniform appearance.

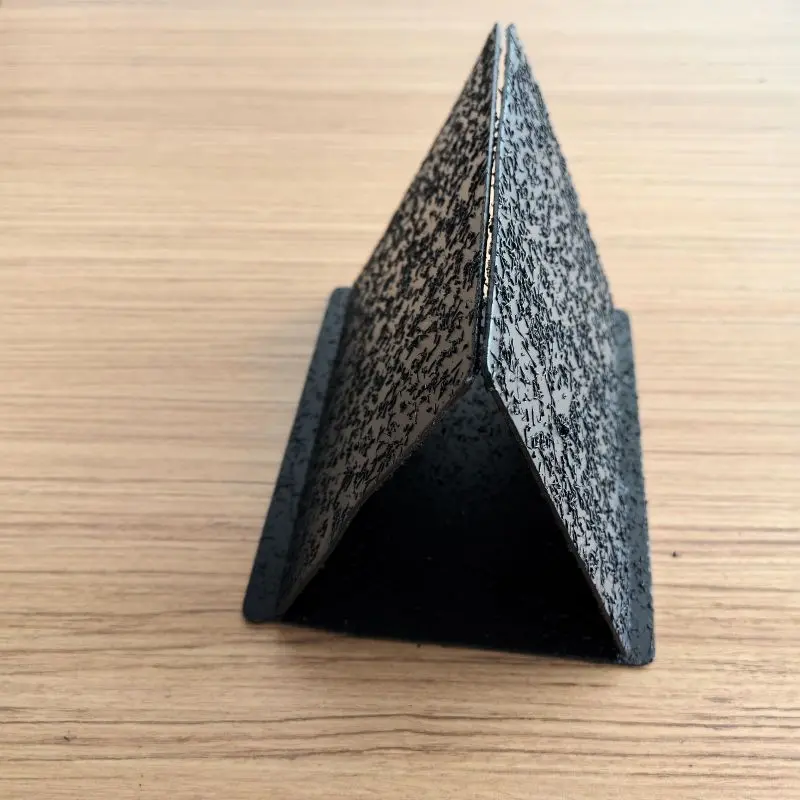

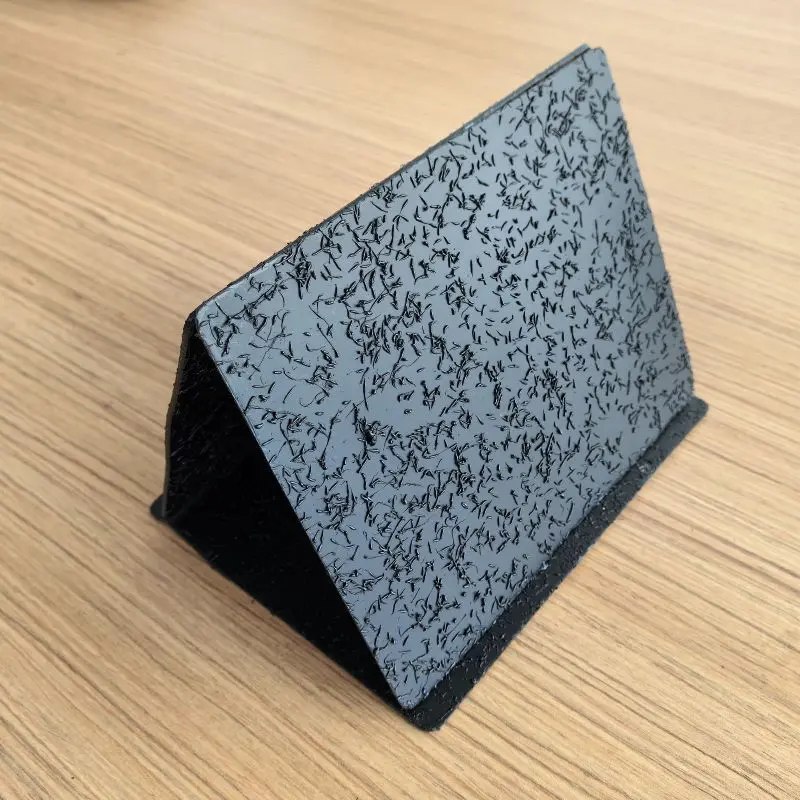

Textured Geomembranes: These liners have a surface with raised or embossed patterns, creating a textured or roughened appearance. The texture can vary, and common patterns include studs, knobs, or diamond-shaped embossments.

Frictional Resistance:

2, Smooth Geomembranes: Due to their smooth surface, these liners typically have lower frictional resistance compared to textured geomembranes. This can impact stability in certain applications.

Textured Geomembranes: The textured surface provides increased frictional resistance, which is advantageous in applications where stability, slope protection, or prevention of slippage is crucial.

3, Stability:

Smooth Geomembranes: While smooth geomembranes offer a clean and consistent appearance, they may be more prone to slippage in certain slope stabilization applications.

Textured Geomembranes: The textured surface enhances stability by providing better resistance to slippage. This makes them suitable for applications where preventing soil erosion and maintaining slope integrity are important.

4, Applications:

Smooth Geomembranes: Commonly used in applications where a sleek and uniform appearance is desired, and where frictional resistance and stability are not the primary considerations. Examples include certain containment applications where the smooth surface is sufficient for preventing seepage.

Textured Geomembranes: Applied in projects where increased frictional resistance, stability, and resistance to slippage are essential. Common applications include landfill liners, slope stabilization, pond and reservoir liners, and other geotechnical projects.

5, Puncture Resistance:

Smooth Geomembranes: While puncture resistance depends on the material, smooth geomembranes may have varying resistance to punctures.

Textured Geomembranes: The textured surface can enhance puncture resistance in certain cases, making them suitable for applications where protection against sharp objects is important.

6, Hydraulic Performance:

Smooth Geomembranes: The smooth surface may offer favorable hydraulic characteristics in certain applications, such as water containment structures.

Textured Geomembranes: The textured surface may impact hydraulic performance, and this is a consideration when designing structures like channels or water conveyance systems.

Top 8 advantages of textured geomembrane

Compared with smooth geofabric membrane, textured geomembranes have several advantages, especially in geotechnical and environmental applications. Here are 8 key advantages:

1, Increased Frictional Resistance:

The textured surface of geomembranes provides enhanced frictional resistance. This is particularly beneficial in slope stabilization and landfill lining applications, where the increased friction helps to prevent slippage.

2, Improved Stability:

The textured pattern contributes to improved stability by reducing the potential for material movement. This is crucial in containment applications, such as lining for ponds or landfills, where stability is essential to prevent leaks and contamination.

3, Better Interface with Soil:

The textured surface enhances the interaction between the geomembrane and the surrounding soil. This can lead to better anchorage and stability, particularly in applications where the membrane is in direct contact with soil or other geotechnical materials.

4, Increased Shear Strength:

Textured geomembranes often exhibit higher shear strength compared to smooth geomembranes. This makes them suitable for applications where shear forces are a concern, such as in slope stabilization or reinforced soil structures.

5, Improved Drainage:

The textured surface allows for better water drainage and reduces the risk of water accumulation between the geomembrane and underlying soil or other materials. This is advantageous in preventing hydrostatic pressure build-up.

6, Resistance to Slippage:

The increased frictional resistance and stability provided by textured geomembranes make them more resistant to slippage or movement on slopes. This is crucial in applications where preventing erosion and maintaining slope integrity are key considerations.

7, Enhanced Puncture Resistance:

Textured geomembranes often exhibit improved puncture resistance compared to smooth counterparts. This is beneficial in applications where protection against sharp objects or external forces is necessary.

8, Compatibility with Plant Growth:

In certain applications, such as green roofs or landscaping projects, textured geomembranes can provide a surface that is more conducive to plant growth. The texture can serve as a substrate for vegetation, contributing to a more environmentally friendly solution.

Applications of textured geomembrane

Textured geomembranes find application in various geotechnical and environmental projects where their unique surface characteristics offer specific advantages. Here are some common application areas for textured geomembranes:

1, Landfill Liners: Textured geomembranes are widely used as liners in landfills. The textured surface provides increased frictional resistance and stability, reducing the risk of slippage and ensuring containment of waste materials.

2, Pond and Reservoir Liners: Geomembranes with textured surfaces are employed in the construction of ponds, reservoirs, and other water containment structures. The enhanced frictional properties help prevent seepage and ensure water retention.

3, Mining and Tailings Storage: In mining operations, where containment of tailings and hazardous materials is critical, textured geomembranes are used to line storage facilities. The textured surface contributes to stability and helps prevent leaks.

4, Wastewater Treatment Plants: Textured geomembranes are utilized in the construction of wastewater treatment plants for lining basins and containment structures. The increased frictional resistance and stability are beneficial in preventing contamination.

5, Slope Stabilization: Geomembranes with textured surfaces are applied in slope stabilization projects. The enhanced friction helps prevent soil erosion and slippage on slopes, contributing to the stability of the terrain.

6, Canal and Channel Liners: Textured geomembranes are used to line canals and channels to prevent water seepage and enhance the hydraulic performance of water conveyance systems.

7, Environmental Containment Barriers: In environmental remediation projects, textured geomembranes may be used as barriers to contain and isolate contaminated soil or groundwater, preventing the spread of pollutants.

FAQ

1, What is the primary purpose of using textured geomembranes?

Textured geomembranes are primarily used to enhance stability and frictional resistance in geotechnical and environmental applications. The textured surface helps prevent slippage on slopes, provides effective containment in landfills, and improves performance in various containment structures.

2, In which applications are textured geomembranes more advantageous than smooth geomembranes?

Textured geomembranes are particularly advantageous in applications where increased frictional resistance, stability, and resistance to slippage are crucial. Common applications include landfill liners, pond and reservoir liners, slope stabilization, and environmental containment barriers.

3, How does the textured surface of geomembranes contribute to slope stabilization?

The textured surface of geomembranes increases frictional resistance, reducing the risk of slippage on slopes. This enhanced stability is vital in preventing soil erosion and maintaining the integrity of slopes in geotechnical projects.

4, Can textured geomembranes be used in applications requiring protection against punctures?

Yes, the texture on geomembranes can contribute to improved puncture resistance. This makes them suitable for applications where protection against sharp objects or potential puncture hazards is a consideration.

5, Are there specific environmental applications where textured geomembranes are commonly employed?

Yes, textured geomembranes are frequently used in environmental applications, such as landfill liners and environmental containment barriers. The textured surface helps ensure effective containment of hazardous materials, preventing their migration into the surrounding environment.

897.webp)

942.webp)

237.webp)