Geotextiles are synthetic materials designed to improve the performance and longevity of civil engineering projects by providing reinforcement, separation, filtration, and drainage functions. There are several types of geotextiles, each engineered to address specific challenges in construction and environmental applications. Here are some common types:

Types of geotextiles fabric based on weaving methods

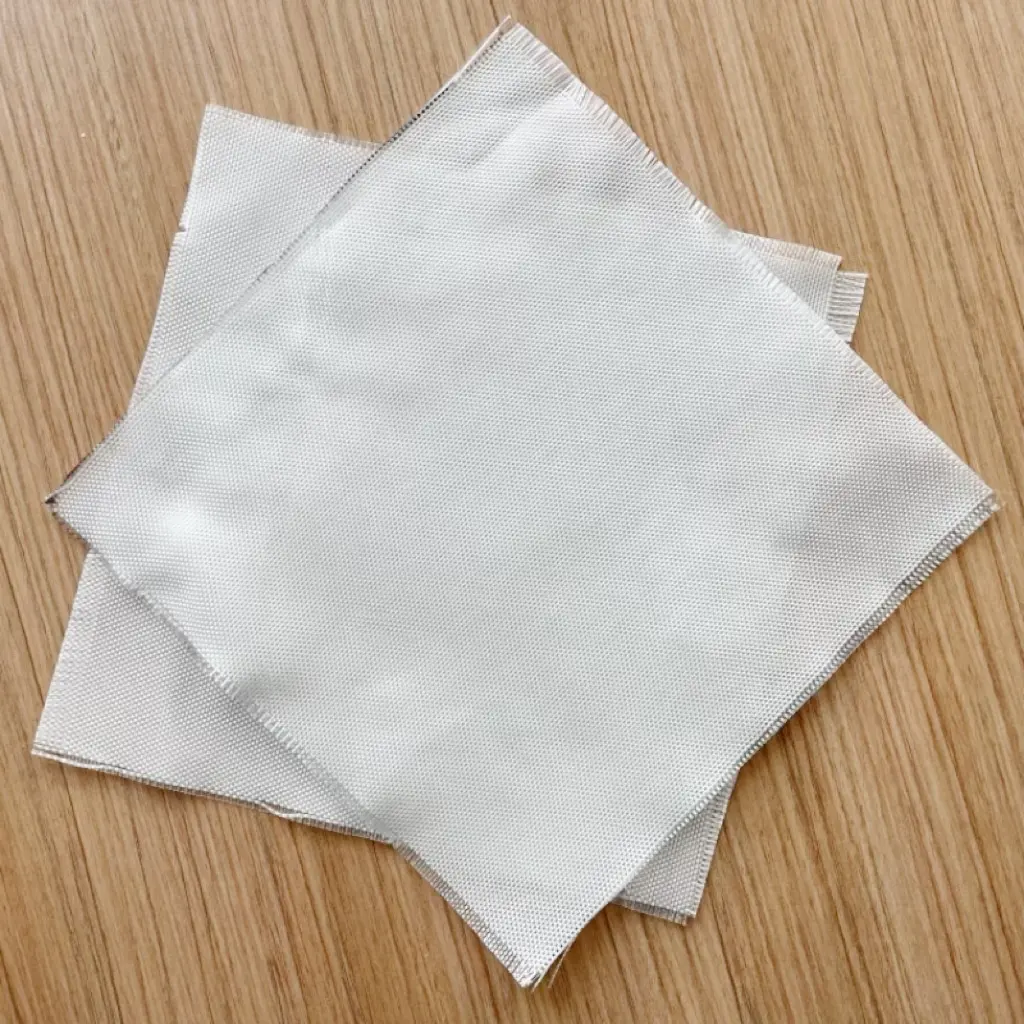

1, Woven Geotextiles fabric

Woven geotextile fabric, also known as woven geotextile, is a geosynthetic material characterized by a combination of strong tensile properties and a relatively thin thickness. Typically available in thicknesses of 0.2mm, 0.4mm, and 0.7mm, this fabric boasts robust tensile strength, approximately 250kg/cm², and a significant permeability coefficient of about 6.1*10^-4cm/s.

Constructed through the interweaving of warp and weft yarns, woven geotextile fabric is composed of parallel yarns forming the warp and weft directions. The warp represents the set of yarns aligned with the longitudinal axis of the weaving machine, while the weft comprises the yarns arranged perpendicular to the machine's direction.

Adaptable to various applications, woven geotextile fabric can be woven to different thicknesses and compaction levels. Generally, it consists of cotton yarns arranged in at least two parallel sets. The fabric exhibits exceptional compressive strength, particularly in the warp direction, providing reliable performance.

Woven geotextile fabric can be categorized into reinforced and unreinforced types, based on variations in manual weaving processes and the application of additional strengthening elements. Reinforced woven geotextile fabric, in particular, demonstrates significantly higher compressive strength in the warp direction compared to conventional geotextiles.

Primarily utilized in geotechnical construction projects, woven geotextile fabric finds application in reinforcement and enhancement of soil structures. Its thin yet resilient nature, coupled with superior compressive strength, makes it an ideal choice for projects where reliable performance and reinforcement are critical.

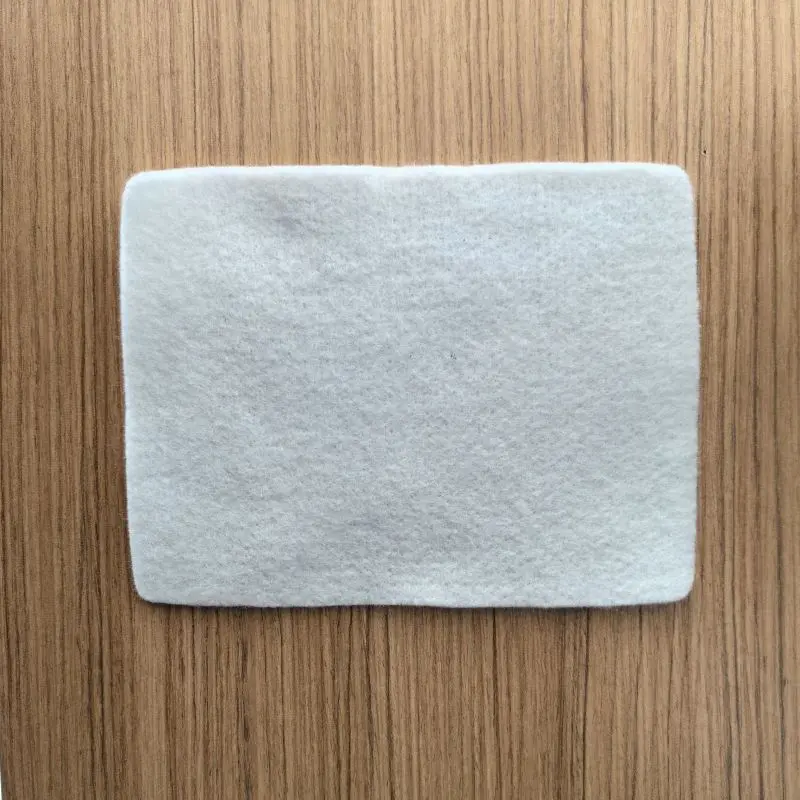

2,Non-woven geotextiles fabric

Non-woven geotextile fabric is produced by arranging polyester filaments or short fibers into a honeycomb structure through different machinery and processing techniques. Following processes such as needle punching, the various chemical fibers are intertwined and interlocked, solidifying the fabric and ensuring standardization. This treatment imparts qualities of softness, fullness, strength, and rigidity to the fabric, exceeding various thickness considerations for specific applications.

Non-woven geotextile fabric exhibits excellent textile porosity, providing superior adhesion and cohesion due to the interlacing of chemical fibers. The softness of the chemical fibers ensures essential tear resistance, and the fabric demonstrates excellent deformation adaptability and drainage capabilities. The surface's softness and multiple voids contribute to effective frictional resistance, enhancing the adhesion of coarse particles and preventing the unnecessary flow of fine particles. This feature helps avoid the removal of unnecessary moisture.

The surface's softness also contributes to excellent maintenance capabilities. Non-woven geotextile fabric can be categorized based on the length of the filaments, such as polyester filament non-woven geotextile fabric or short-fiber non-woven geotextile fabric. Both types offer outstanding filtration, protection, reinforcement, and safety functions, making them widely used as geosynthetic materials in various engineering applications.

3,Comparison

1), Strength and Load Distribution:

Woven geotextiles have a significant advantage in terms of tensile strength and load distribution, making them preferable for projects where these characteristics are critical.

2), Filtration and Drainage:

Non-woven geotextiles outperform woven types in terms of filtration and drainage capabilities. They are more suitable for applications where water permeability and filtration efficiency are paramount.

3), Versatility:

Both woven and non-woven geotextiles have versatile applications. The choice between the two depends on specific project requirements and priorities.

In conclusion, the selection of geotextiles depends on the specific needs of a project. Woven geotextiles offer strength and stability, while non-woven geotextiles excel in filtration and drainage. Engineers and construction professionals must carefully consider these factors to ensure the optimal performance of geotextile materials in their projects.

Types of geotextiles fabric based on raw meterials

1, Polypropylene Geotextiles Fabric

Polypropylene geotextile is a geosynthetic material made from polypropylene fibers. Typically produced in fiber form through various manufacturing processes such as weaving and melt spinning, polypropylene geotextile finds widespread application in civil engineering and construction. Its characteristics include:

Characteristics:

1), Weather Resistance: Polypropylene geotextile exhibits strong weather resistance, ensuring long-term stability under different climatic conditions.

2), Chemical Stability: Possesses stability against various chemical substances, maintaining resilience in environments exposed to soil and water.

3), Lightweight: Being a lightweight material, polypropylene geotextile itself is relatively easy to handle, transport, and install.

4), Abrasion Resistance: Demonstrates a certain level of abrasion resistance, maintaining integrity under soil movement and other external forces.

5), Tensile Strength: Possesses high tensile strength, suitable for reinforcing soil structures and dispersing loads.

This geotextile material serves various functions in civil engineering and construction projects, providing solutions for soil stabilization, erosion control, and reinforcement applications.

2, Polyester Geotextiles Fabric

Polyester geotextile is a geosynthetic material made from polyester fibers. Polyester is a synthetic fiber known for its excellent durability and chemical stability. Widely used in civil engineering and construction, the characteristics of polyester geotextile include:

Characteristics:

1), High Strength: Polyester geotextile exhibits high tensile strength, effectively dispersing loads and enhancing the soil's tensile performance.

2), Weather Resistance: Possesses good weather resistance, maintaining stability under various climatic conditions and resisting the impact of natural environments.

3), Chemical Corrosion Resistance: Demonstrates good stability against certain chemical substances, maintaining performance when exposed to different soil and water conditions.

4), Abrasion Resistance: Has a certain level of abrasion resistance, allowing it to maintain integrity under soil movement and other external forces.

5), Flexibility: Polyester geotextile is relatively soft, making it easy to install and adapt to irregular surfaces.

This geotextile material serves multiple purposes in civil engineering and construction, providing solutions for soil stabilization, erosion control, and reinforcement applications.

3,Polyethylene Geotextiles Fabric

131833.webp)

Polyethylene geotextile is a geosynthetic material made from polyethylene. Polyethylene is a thermoplastic polymer known for its lightweight, flexibility, and resistance to chemical corrosion. Widely utilized in civil engineering and construction, the characteristics and of polyethylene geotextile include:

Characteristics:

1), Lightweight: Polyethylene geotextile is a lightweight material, facilitating easy handling, installation, and processing.

2), Flexibility: Exhibits high flexibility, with strong adaptability to irregular surfaces and terrains.

3), Chemical Corrosion Resistance: Polyethylene demonstrates good stability against common chemical substances, maintaining performance under various environmental conditions.

4), Abrasion Resistance: Possesses a certain level of abrasion resistance, maintaining integrity under external forces.

5), Anti-Aging: Has a degree of resistance to aging, enabling it to maintain stability for extended periods in outdoor environments.

This geotextile material plays a crucial role in civil engineering and construction projects, providing solutions for soil stabilization, erosion control, and reinforcement applications.

4, Comparation

In terms of tensile strength, polypropylene geotextiles demonstrate a relatively high tensile strength, while polyester geotextiles exhibit high tensile strength, particularly suitable for projects with demanding strength requirements. Polyethylene geotextiles provide a moderate level of tensile strength. Regarding chemical corrosion resistance, polypropylene geotextiles exhibit excellent resistance, polyester geotextiles display good chemical stability, and polyethylene geotextiles offer a certain level of resistance.

In terms of applications, polypropylene geotextiles are suitable for projects requiring lightweight, high strength, and chemical stability. Polyester geotextiles are applicable to projects with high demands for tensile strength and durability. Polyethylene geotextiles are suitable for projects where lightweight and flexibility are crucial. The choice of the appropriate geotextile depends on the specific requirements and conditions of the individual engineering project, considering factors such as strength, durability, and chemical stability.

The above is a general classification of geotextiles fabric. If you are interested in geotextiles, please feel free to contact us, we are a leading geosynthetic products manufacturer in China, our factory can supply all kinds of geotextiles fabric products. Looking forward to establish business relationship with you.

897.webp)

942.webp)

237.webp)