What Are Geosynthetic Clay Liners (GCLs)?

Geosynthetic Clay Liners are engineered products consisting of a layer of natural sodium bentonite clay sandwiched between two geotextiles or bonded to a geomembrane. These liners are widely used in environmental engineering due to their low permeability and excellent sealing properties. The bentonite clay hydrates when exposed to water, creating a barrier that effectively restricts liquid migration.

Composition of Geosynthetic Clay Liners (GCLs)

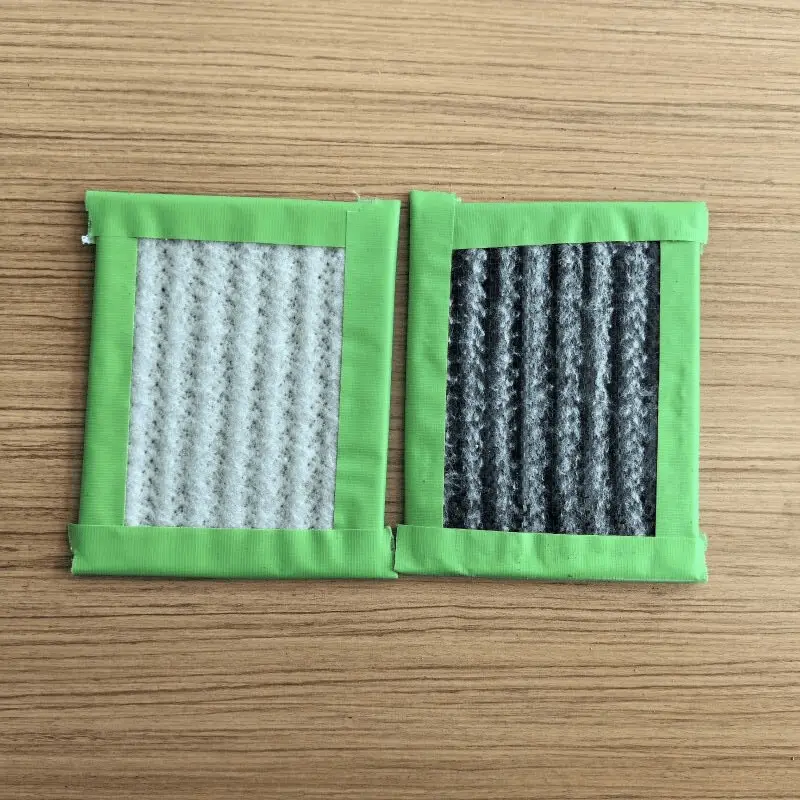

Ø Geotextile Layers:

o Woven or nonwoven geotextiles.

o These layers provide mechanical strength and support.

Ø Bentonite Clay Core:

o Sodium bentonite is the most common type used due to its high swelling capacity.

o Encased between geotextiles or bonded to one layer of geomembrane.

Ø Optional Geomembrane Layer:May include an additional polymeric liner for added impermeability.

Ø Needle-Punching or Stitch-Bonding: These methods are used to force the layers, preventing clay migration and improving shear strength.

Typical Specifications of Geosynthetic Clay Liners (GCLs)

Ø Thickness:

o Ranges from 5 mm to 10 mm depending on the product.

Ø Hydraulic Conductivity:

o Typically 10−9 m/s10^{-9} , ext{m/s}10−9m/s or lower when hydrated and under confining pressure.

Ø Mass per Unit Area:

o Commonly 4 to 6 kg/m² for the bentonite layer.

Ø Swelling Capacity:

o High-quality sodium bentonite can swell up to 15 times its dry volume.

Ø Shear Strength:

o Dependent on the type of geotextile and clay used, typically ranging from 25 to 50 kPa.

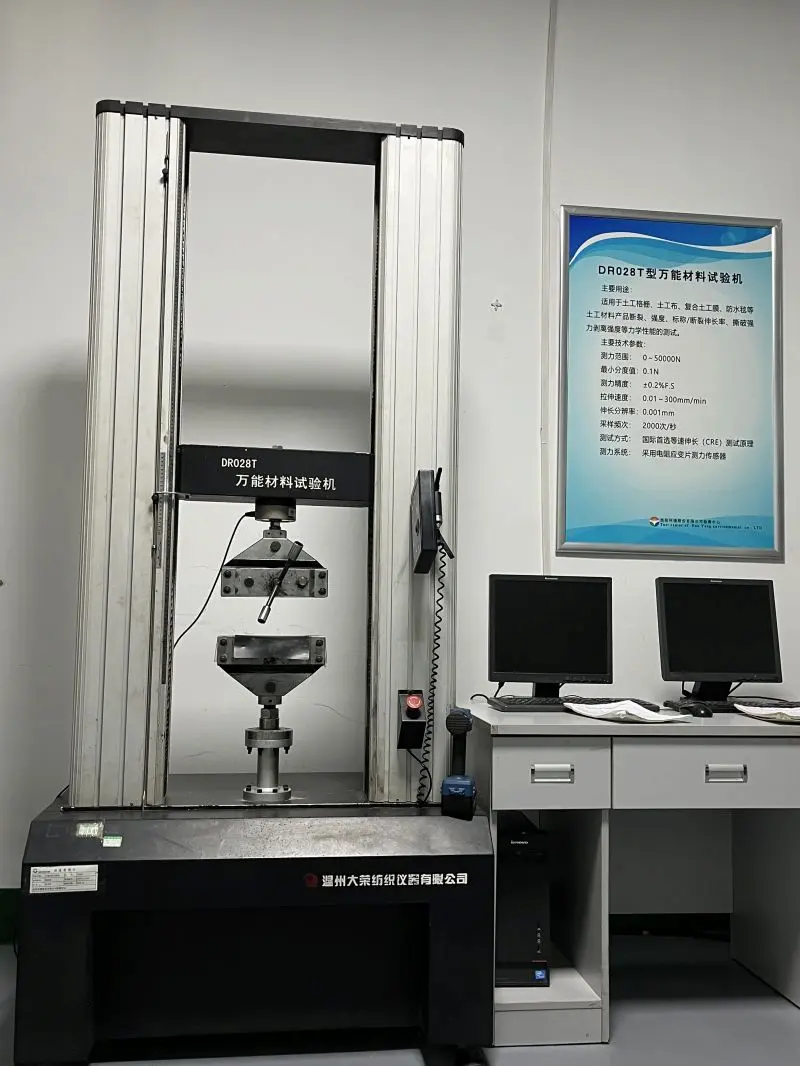

Ø Peel and Shear Strength:

o Strength of the bond between geotextiles or geomembrane layers, tested per ASTM standards.

Ø Chemical Resistance:

o Resists a wide range of chemicals; performance depends on the bentonite and polymer additives.

Ø Temperature Resistance:

o Operational range typically between -30°C to +60°C.

Key Features of Geosynthetic Clay Liners (GCLs)

Feature | Description |

Low Permeability | Bentonite clay’s swelling properties ensure extremely low water permeability. |

Flexibility | GCLs can conform to uneven surfaces, reducing installation challenges. |

Lightweight | Easier and less costly to transport and install compared to traditional clay liners. |

Chemical Resistance | Resistant to a variety of chemicals, making them suitable for hazardous waste containment. |

Durability | Long service life under typical environmental conditions. |

Prices of Geosynthetic Clay Liners (GCLs)

The cost of GCLs depends on factors such as material composition, thickness, and project-specific requirements. Below is an approximate pricing breakdown:

Type of GCL | Price Range (USD per square meter) |

Standard Bentonite GCL | $2.50 - $4.50 |

Reinforced GCL with Geomembrane | $4.00 - $7.00 |

Custom-engineered GCL | $6.00 - $10.00 |

Note: Prices may vary based on region, supplier, and order volume.

Applications of Geosynthetic Clay Liners (GCLs)

GCLs are used in various industries due to their versatility and effectiveness. Common applications include:

1. Landfills

o Acts as a base liner and cap liner to prevent leachate migration.

o Enhances overall containment integrity.

2. Mining Operations

o Used in tailings ponds and heap leach pads to contain hazardous chemicals.

3. Water Containment

o Ideal for reservoirs, canals, and dams due to their waterproofing capabilities.

4. Industrial Waste Containment

o Provides barriers for hazardous waste storage facilities.

5. Transportation Projects

o Applied in road and railway embankments to control water seepage.

Advantages of Geosynthetic Clay Liners(GCLs)

Advantage | Explanation |

Cost-Effective | Requires less material and labor compared to traditional clay liners. |

Quick Installation | Requires less material and labor compared to traditional clay liners. |

Environmentally Friendly | Uses natural bentonite clay, reducing environmental impact. |

Performance | High resistance to water and many chemicals ensures long-term reliability. |

Disadvantages of Geosynthetic Clay Liner(GCLs)

Disadvantage | Mitigation Strategy |

Hydration Issues | Ensure proper moisture content during installation to prevent cracking. |

Susceptibility to Punctures | Protect with geomembrane or appropriate overlying materials. |

Dependency on Overburden | Requires sufficient confining pressure to maintain low permeability. |

Chemical Compatibility | Conduct compatibility tests for highly aggressive chemicals. |

Performance Metrics

The effectiveness of GCLs can be measured using key parameters:

Property | Typical Value |

Hydraulic Conductivity | 1 × 10⁻¹° to 1 × 10⁻¹± cm/s |

Swell Index (Bentonite) | ≥20 mL/2 g |

Tensile Strength | ≥20 kN/m |

Peel Strength | 3.5 N/m |

Standards and Testing of Geosythetic Clay Liners (GCLs)

GCLs must meet specific international or national standards, such as:

1.ASTM International Standards

Ø ASTM D5887: Test Method for Measurement of Index Flux Through Saturated GCL Specimens Using a Flexible Wall Permeameter.

Ø ASTM D5890: Test Method for Swell Index of Clay Mineral Component of GCLs.

Ø ASTM D5891: Test Method for Fluid Loss of Clay Component of GCLs.

Ø ASTM D5993: Test Method for Measuring the Mass per Unit Area of GCLs.

Ø ASTM D6102: Guide for Installation of GCLs.

2.ISO Standards

Ø ISO 10318: Geosynthetics — Terms and Definitions (includes GCL classification).

Ø ISO 10773: Test Methods for Determining Hydraulic Properties of GCLs.

3. Regional Standards

Ø pean Standards (EN)

o EN 14196: Geosynthetic barriers — Test methods for water permeability properties of GCLs.

o EN 16416: Geosynthetic barriers — Characteristics required for use in the construction of reservoirs and dams.

Ø Australian Standards

o AS 3706: Series of geosynthetic test methods (specific methods may be relevant to GCLs).

Ø German Standards (DIN)

o DIN 18195: Waterproofing methods, applicable to GCLs in various construction contexts.

Case Studies

1. Landfill in California

o Objective: Prevent leachate leakage.

o Solution: Installed a GCL reinforced with geomembrane.

o Result: Reduced permeability to below regulatory limits, saving 30% on project costs compared to traditional liners.

2. Reservoir in Australia

o Objective: Enhance water retention.

o Solution: Deployed GCL in combination with compacted clay.

o Result: Achieved 95% reduction in water loss due to seepage.

Maintenance and Longevity

Proper installation and maintenance are critical for maximizing the lifespan of GCLs. Here are some recommendations:

Ø Inspection: Regularly inspect for signs of wear or damage.

Ø Repair: Promptly address punctures or hydration issues.

Ø Compatibility Testing: Assess chemical compatibility with stored substances.

Conclusion

Geosynthetic Clay Liners are a cutting-edge solution for a wide range of containment applications. Their unique properties, cost-effectiveness, and versatility make them an excellent choice for industries seeking reliable and environmentally friendly barrier solutions. While challenges exist, they can be effectively mitigated with proper planning and execution. For projects requiring durable and efficient containment solutions, GCLs offer a proven path to success. Whether for landfills, mining, or water reservoirs, they are an investment in sustainable engineering.

760993.webp)

897.webp)

942.webp)

237.webp)