What is GCL?

GCL, also called geosynthetic clay liner, also known as a bentonite waterproofing blanket, is a composite material comprised of bentonite clay and synthetic materials, typically polymers. It is commonly used in waterproofing and soil protection projects, offering excellent waterproofing and impermeability properties.

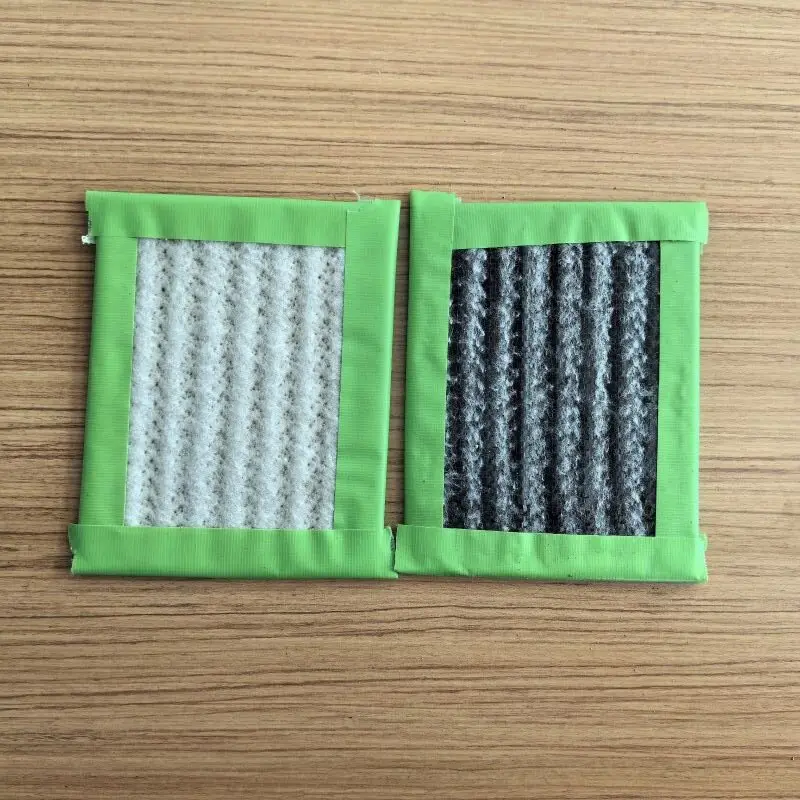

The waterproof blanket is made of three materials: GCL bentonite, PP woven fabric, and short fiber geotextile fabric. Through needle punching, the bentonite particles are fixed between the geotextile fabric and the plastic woven fabric to form a sheet-like waterproofing membrane. When the bentonite absorbs water, it expands into a dense gel within the limited space between the upper and lower layers of non-woven fabric, effectively preventing water leakage. The waterproofing mechanism relies on the sodium-based particles in the GCL bentonite, which can expand more than 24 times upon contact with water, forming a uniform, highly viscous, and low-filtration colloid system. Under the confinement of the two layers of geotextile fabric, the bentonite transitions from disorderly expansion to orderly expansion, achieving compaction and providing waterproofing properties.

Key characteristics of GCL

924986.webp)

As we can see from the above picture, because of its unique structure layers, compared to compacted clay liners, it has the advantages of small volume, light weight, flexibility, excellent sealing, easy construction, and adaptability to uneven settlement. The key characteristics of GCL include:

1, Waterproofing Performance: Geosynthetic clay liners exhibit outstanding waterproofing capabilities, effectively preventing water from permeating into underground structures, thus safeguarding infrastructure from water erosion.

2, Flexibility: Due to the inclusion of elastic materials like polymers, geosynthetic clay liners possess a degree of flexibility, enabling them to adapt to the shape and terrain variations of the surface, ensuring construction quality.

3, Chemical Resistance: Geosynthetic clay liners typically demonstrate good chemical stability, resisting erosion from acids, alkalis, and other chemical substances, thereby extending their service life.

4, Environmental Friendliness: Utilizing synthetic materials, some products incorporate renewable resources, contributing to their environmental friendliness to a certain extent.

Applications of geosynthetic clay liner

1, Landfills: GCLs are widely used as bottom liners and caps in landfills to prevent the leaching of contaminants into the soil and groundwater. They contribute to the environmental protection and containment of waste materials.

2, Artificial Lakes and Ponds: GCLs are used to line the bottoms and sides of artificial lakes and ponds, providing a waterproof barrier that helps retain water and prevent seepage.

3, Water Containment and Reservoirs: GCLs are employed in the construction of water containment structures, such as reservoirs and dams, to create impermeable barriers that prevent water from escaping.

4, Mining Applications: GCLs are used in mining operations to line tailings ponds and storage facilities, preventing the release of potentially harmful substances into the surrounding environment.

5, Oil and Gas Industry: GCLs are applied in the construction of containment structures for oil depots, chemical storage yards, and other facilities in the oil and gas industry to prevent leakage of hazardous substances.

6, Wastewater Treatment: GCLs can be employed in wastewater treatment facilities to line lagoons and containment structures, preventing the seepage of treated or untreated wastewater into the surrounding soil.

In a word, the versatility and effectiveness of GCLs make them valuable in a wide range of applications where impermeability and containment are critical considerations. The specific application depends on the project requirements and the environmental conditions of the site.

Main specifications we can supply

Technique specifications

395196.webp)

The above is the main technical indicators of GCL, when you choose the products, you can check if these values can meet your requirements.

The size of GCL

1, Unit area mass: ≥4000g/m²

Usually, you can choose 4000g/m², 4500g/m², 4800g/m² , 5000g/m², 5500g/m²according to your needs. The higher the weight, the higher the price.

2, Width: 4-6m

The width of the roll can also be customized, according to your project size, you can choose 3m, 5m 6m or other size. but considering of the length of the container, it isusually less than 5.8m.

3, The length of the roll

The length of the roll can be any size accoring to your need, our customer usually choose 50m, 100m, etc.

Hope this information can help you when you choose the specificaions of GCL, and if you need this product, fell free to contact me:

Echo: phone/wechat/whatsapp: 0086-18853127527

email: export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)