What is geosynthetic clay liners(GCL)

Geosynthetic clay liners (GCLs) are revolutionary composite materials extensively employed in civil engineering and environmental projects for containment, waterproofing, and soil stabilization purposes. Consisting of geotextile or geomembrane layers surrounding a core of sodium bentonite clay, GCLs derive their exceptional characteristics from the bentonite clay core, which grants them high hydraulic conductivity, swelling capacity, and self-sealing capabilities.

Characters of Bentonite

1,Water-absorbing and swelling properties: It has hygroscopicity, capable of absorbing 8-15 times its own volume of water. Upon water absorption, it expands, with an expansion ratio of 20-30 times its original volume.

2,Dispersibility and suspension: Bentonite exists in a colloidal dispersed state in solution (with fine particles carrying the same negative charge).

3,Adhesiveness: The colloidal suspension of bentonite has high viscosity (due to friction between particles and molecules).

4,Thixotropy: The colloidal solution becomes thinner when stirred and thickens when at rest.

5,Ion exchangeability: The most common exchangeable cations are calcium and sodium ions.

6,Non-toxicity: It is non-toxic to humans, animals, and plants.

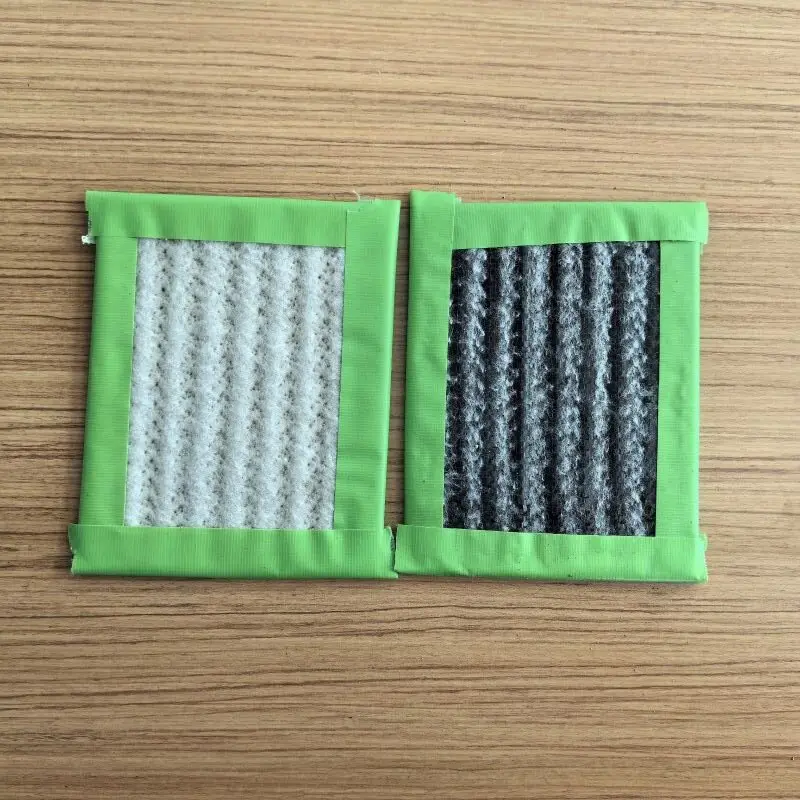

Features of GCL

700930.webp)

GCL has High cost-performance ratio and extensive applicability. The product can reach widths of up to 6 meters, significantly improving construction efficiency.

Applicable Range and Application Conditions: Suitable for municipal (landfills), water conservancy, environmental protection, artificial lakes, underground waterproofing, and anti-seepage engineering in construction. It can be applied even in negative temperatures (-20°C) where traditional waterproofing materials cannot be used. It can also be applied on damp substrates (but not where there is standing water). However, it cannot be applied in rainy or snowy weather. It is not suitable for preventing seepage of strong acid or alkali solutions. Due to its inorganic nature, bentonite exhibits better durability compared to organic waterproofing materials.

1,Compactness: Sodium-based bentonite forms a high-density barrier membrane under water pressure. When the thickness is about 3mm, its permeability is below 10^-11m/sec, equivalent to 100 times the compactness of 30cm thick clay. It has strong self-sealing properties.

2,Permanent waterproofing performance: As sodium-based bentonite is a natural inorganic material, it does not age or corrode even after a long time or changes in the surrounding environment, thus ensuring long-lasting waterproofing performance.

3,Easy construction, short construction period: Compared to other waterproofing materials, construction is relatively simple, requiring no heating or pasting. It only needs bentonite powder, nails, washers, etc., for connection and fixation. There is no need for special inspections after construction, and any waterproof defects found are easily repairable. GCL has the shortest construction period among existing waterproofing materials.

4,Not affected by temperature: It does not become brittle even under cold weather conditions.

Integration of waterproofing material and object: When sodium-based bentonite encounters water, it expands 20-28 times, so even if concrete structures experience vibration and settlement, the bentonite inside the GCL can repair cracks on the concrete surface within 2mm.

5,Green and environmentally friendly: Bentonite is a natural inorganic material, harmless and non-toxic to the human body, with no significant impact on the environment, and it possesses excellent environmental performance.

Technical Parameters

Bentonite swelling index (ml/2g) ≥ 24;

GCL unit area mass (g/m2) ≥ 4500;

GCL longitudinal tensile strength (KN/m) ≥ 10;

GCL transverse tensile strength (KN/m) ≥ 10;

GCL longitudinal elongation at break (%) ≤ 10;

GCL transverse elongation at break (%) ≤ 6;

GCL vertical permeability coefficient (cm/s) ≤ 5×10^-9;

GCL peel strength (N) ≥ 65;

GCL hydraulic conductivity test (0.5 MPa) with no leakage for 24 hours.

Functions of GCLs

GCLs serve multiple functions in environmental engineering projects, including:

Containment: GCLs act as effective barriers to prevent the migration of liquids, gases, and contaminants in landfills, ponds, reservoirs, and other containment structures.

Waterproofing: GCLs provide reliable waterproofing solutions for below-ground structures, such as basements, tunnels, and underground storage tanks, by creating impermeable barriers against water infiltration.

Erosion Control: GCLs are used to stabilize slopes, embankments, and channels, preventing soil erosion and promoting vegetation growth in erosion-prone areas.

Installation and Performance

GCLs are installed by unrolling and overlapping individual rolls or panels to create continuous liner systems. During installation, hydration of the bentonite clay core occurs, resulting in the swelling of the GCL and the formation of a tight seal against adjacent surfaces. Proper installation techniques and quality control measures are essential to ensure the performance and longevity of GCLs in service.

Construction Method

1,GCL materials are heavy and should be transported and laid using a shovel loader.

2,The connection of GCL materials should be overlapped.

3,When laying GCLs on slopes greater than 10%, the number of overlaps along the slope length should be minimized, and the bentonite cushion on the slope must exceed 1500mm from the slope toe.

4,Any equipment used for laying GCL must not drive on already laid geosynthetic materials. When installing GCL, the outdoor air temperature should not be below 0°C or above 40°C.

5,All exposed edges of GCLs must be immediately pressed down with sandbags or other heavy objects to prevent them from being blown away by the wind or pulled out by surrounding anchoring ditches. GCLs should not be unfolded in windy conditions to prevent them from being lifted by the wind.

6,The laying method of GCLs must ensure direct contact with the underlying foundation and eliminate wrinkles. Any wrinkles, folds, or bulges may cause similar situations in other soil-based materials. To avoid wrinkles, folds, and bulges, we will redistribute or cut and repair the GCL according to the technical specifications.

Equipment for GCLs must be approved by the supervising engineer before use, and unprotected razors or "utility knives" are not allowed. Construction equipment that may damage the bentonite blanket cannot directly act on the bentonite blanket. A feasible laying method is to drive backward with the bulldozer, laying out the bentonite blanket from the front end of the bulldozer. If the bulldozer leaves tire prints on the subgrade soil, they should be restored before continuing with the laying work.

7,When laying GCLs, minimize dragging them on the subgrade to avoid damaging the contact surface between the bentonite blanket and the ground. If necessary, a temporary geotextile layer can be added to the ground to reduce damage caused by friction during the laying process.

8,The laying and overlapping of bentonite blankets should be parallel to the direction of the sloping slope. If the slope ratio is greater than 4:1, there should be no transverse overlap within 1m from the slope top or slope. Overlapping: The overlapping method of bentonite blankets is to overlap the ends of two bentonite blankets. Measures should be taken to prevent soft soil or debris from entering the overlap area.

As a leading manufacturer in China, we specialize in the production and wholesale distribution of Geosynthetic Clay Liners (GCLs). Our state-of-the-art facilities and expertise in polymer technology enable us to produce high-quality GCLs that meet international standards for containment, waterproofing, and soil stabilization applications. With a commitment to innovation and quality assurance, we strive to deliver cost-effective and reliable solutions to meet the diverse needs of our customers in the civil engineering and environmental sectors. Partner with us for superior GCL products and exceptional service tailored to your project requirements. Our factory can produce GCL. 20000㎡ everyday, our products have been exported to many countries, If you are interested in our products, please contact Echo:

Phone/Whatsapp: 0086-18853127527

email: export@hygeosynthetics.com

897.webp)

942.webp)

237.webp)