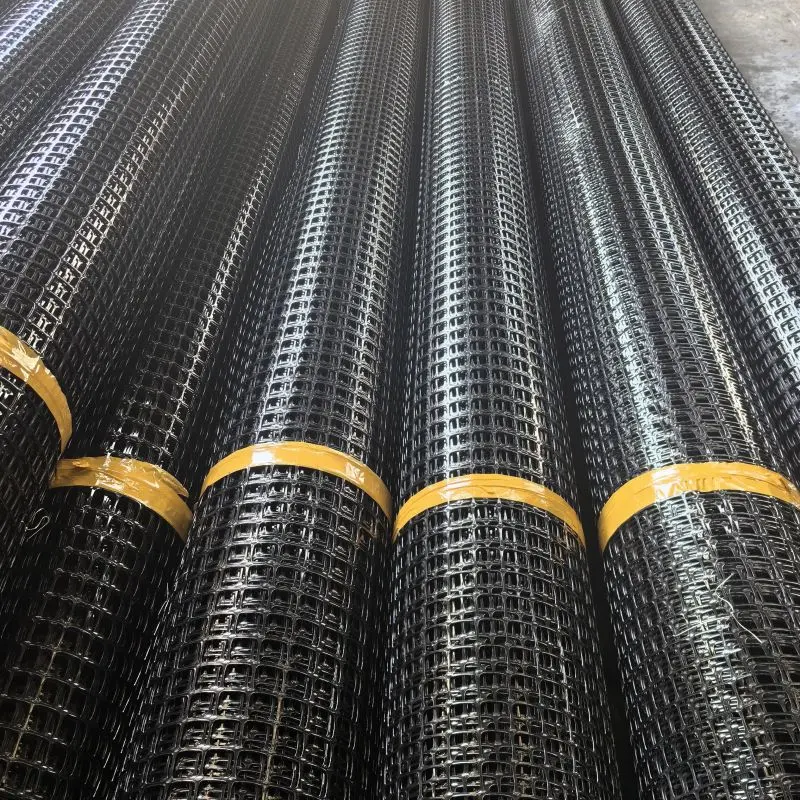

What is plastic steel geogrid

Plastic steel geogrid is a type of geosynthetic material used primarily for soil reinforcement and stabilization in civil engineering and construction projects. Combining the benefits of both plastic and steel, it offers enhanced strength, durability, and versatility, making it an ideal choice for various applications such as road construction, retaining walls, and embankment stabilization.

Composition and Structure

Plastic steel geogrids are made by combining high-density polyethylene (HDPE) or polypropylene (PP) with steel wire or strips. The plastic matrix provides flexibility and resistance to environmental degradation, while the embedded steel components add significant tensile strength and rigidity. This hybrid structure results in a geogrid that can withstand heavy loads and resist deformation under stress.

Types of Plastic Steel Geogrids

Uniaxial Plastic Steel Geogrid: Designed to provide strength primarily in one direction, uniaxial geogrids are used in applications where loads are predominantly applied in a single direction, such as in retaining walls and steep slopes.

Biaxial Plastic Steel Geogrid: These geogrids offer strength in two perpendicular directions, making them suitable for applications like road bases and sub-bases where loads are distributed in multiple directions.

Triaxial Plastic Steel Geogrid: With strength in multiple directions, triaxial geogrids provide exceptional stability and are used in more complex construction scenarios, such as in areas with variable load distributions.

Key Benefits

High Tensile Strength: The integration of steel provides plastic steel geogrids with high tensile strength, allowing them to effectively distribute loads and reduce the risk of deformation.

Durability: The plastic component ensures resistance to environmental factors such as UV radiation, chemical exposure, and moisture, while the steel component offers robust structural support.

Flexibility: Despite their strength, plastic steel geogrids maintain a degree of flexibility, making them easy to handle and install in various construction settings.

Cost-Effectiveness: By reducing the need for thick aggregate layers and improving load distribution, plastic steel geogrids can lower construction and maintenance costs.

Applications

Road Construction: Used to reinforce base and sub-base layers, plastic steel geogrids improve the load-bearing capacity of roads, reduce rutting, and extend pavement life.

Retaining Walls: These geogrids provide essential reinforcement for retaining walls, helping to stabilize the soil and prevent wall failure.

Embankment Stabilization: In embankment projects, plastic steel geogrids enhance stability by distributing loads and preventing soil erosion and settlement.

Soft Soil Reinforcement: They are particularly effective in areas with weak or soft soils, where their strength and stability can prevent subsidence and improve load distribution.

Railway Construction: Plastic steel geogrids are also used in railway construction to stabilize tracks and reduce maintenance needs by enhancing the load distribution.

Installation

The installation of plastic steel geogrids involves several key steps:

Site Preparation: The construction site must be cleared and leveled to provide a stable foundation for the geogrid installation.

Geogrid Placement: The geogrids are unrolled and placed over the prepared surface, ensuring proper alignment and overlap between sections to maintain continuity.

Anchoring and Fixing: The geogrids are anchored and fixed in place using suitable methods, such as stakes or anchor pins, to prevent movement during the construction process.

Covering and Compaction: Once the geogrids are in place, they are covered with aggregate or soil, and the layers are compacted to achieve the desired level of stability and load distribution.

Future Prospects

The use of plastic steel geogrids is expected to grow as the demand for durable, cost-effective, and sustainable construction materials increases. Advances in material science and manufacturing techniques will likely lead to the development of even stronger and more versatile geogrids, further expanding their applications in civil engineering and construction.

In summary, plastic steel geogrids represent a significant advancement in geosynthetic materials, offering a powerful combination of strength, durability, and flexibility. Their role in modern construction is pivotal, providing solutions that enhance the stability and longevity of various infrastructure projects. As technology and innovation continue to evolve, the potential applications and benefits of plastic steel geogrids will undoubtedly expand, contributing to more resilient and sustainable construction practices worldwide.

Plastic Steel Geogrids Supplier

Introducing our esteemed company as a leading supplier of plastic steel geogrids, we pride ourselves on offering premium quality products that meet the highest industry standards. Our plastic steel geogrids are engineered with advanced materials and innovative designs, ensuring exceptional strength, durability, and flexibility for a wide range of civil engineering and infrastructure projects.

As a trusted partner, we specialize in providing customized solutions tailored to our clients' specific requirements. Whether it's for soil reinforcement, retaining walls, slope stabilization, or pavement reinforcement, our geogrids deliver unparalleled performance and cost-effectiveness.

Backed by a team of experienced engineers and a state-of-the-art manufacturing facility, we ensure every product undergoes rigorous quality control checks to maintain consistency and reliability. Our commitment to excellence extends beyond product delivery, with exceptional customer service and timely support throughout the project lifecycle.

Choose us as your plastic steel geogrid supplier and experience the difference of working with a company that values quality, innovation, and customer satisfaction above all else. Let's collaborate to build stronger, more sustainable infrastructures together.

897.webp)

942.webp)

237.webp)