White and Green Mountain Protection Special Composite Drainage Net

Introducing the White and Green Mountain Protection Special Composite Drainage Net, a cutting-edge solution designed for effective drainage and erosion control in various environmental and engineering applications. Developed by Haoyang Environmental Co., Ltd., a leader in high-tech environmental services and geosynthetic materials, this innovative product exemplifies our commitment to sustainability and advanced engineering.

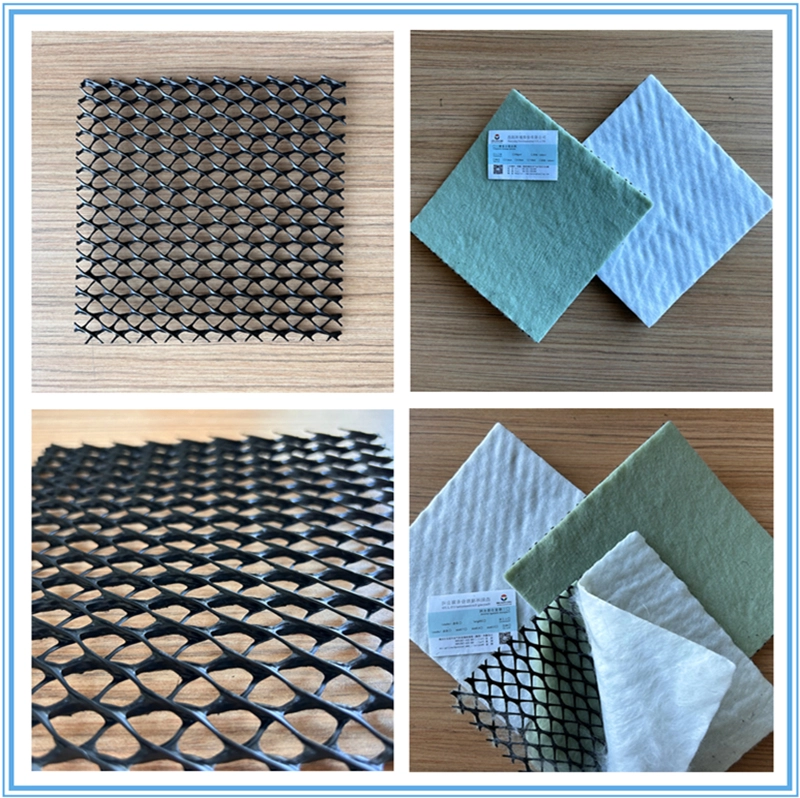

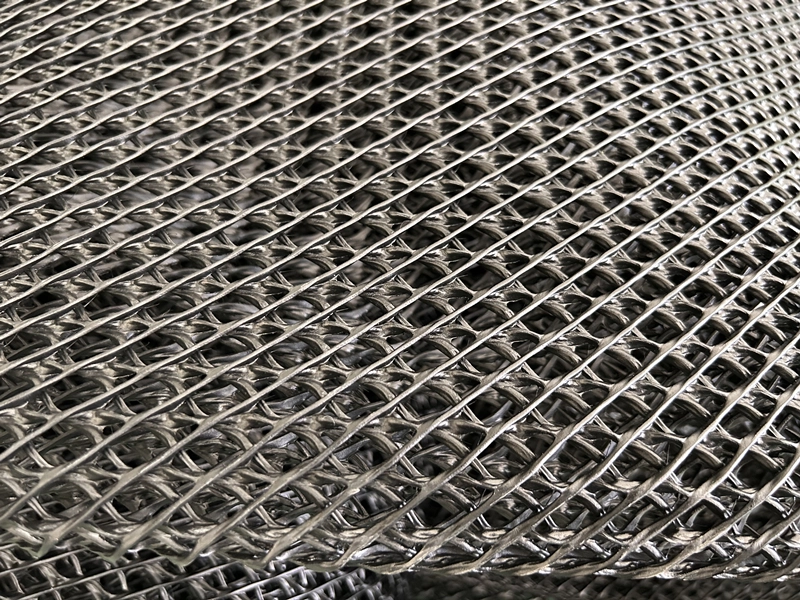

The Drainage Net

Geodrainage mesh is a type of geomaterial used in drainage systems, usually made of polymer material, with a porous mesh structure. It is designed to provide effective water discharge and drainage in underground works. These grid structures disperse water pressure and promote the flow of water, thus avoiding water retention in the soil, helping to stabilize the soil and prevent the water table from becoming too high. Geotechnical drainage net is usually used in roadbed, retaining wall, riverbank engineering and other civil engineering that needs drainage.

Composite geodrainage net is a kind of drainage system composed of different materials, using the thermal bonding process on one side or two sides of the geotextile composite with filter effect formed geodrainage materials. Usually includes geotextile, geomembrane and drainage core layer. This structure combines the isolation and protection function of geotextile or geomembrane, and the drainage function of the drainage core layer. It is designed to provide effective drainage and soil protection while preventing water retention in the soil and reducing groundwater pressure. Composite geotechnical drainage net is often used in roads, tunnels, slopes and other projects to solve the problems of drainage and soil stability.

The core of the drainage net has two or three ribs. Our company uses three ribs, that is, 3D composite drainage net core.

Product Advantages

Superior Drainage Efficiency: The composite structure of our drainage net ensures optimal water flow, preventing waterlogging and enhancing soil stability.

Durability and Longevity: Made from high-quality materials, the drainage net is resistant to chemical and biological degradation, ensuring long-term performance even in harsh environmental conditions.

Environmental Protection: Our product is designed to reduce soil erosion and promote vegetation growth, making it ideal for mountainous terrains and ecologically sensitive areas.

Easy Installation and Maintenance: The lightweight and flexible design allows for quick and easy installation, reducing labor costs and time. Additionally, minimal maintenance is required, ensuring a cost-effective solution.

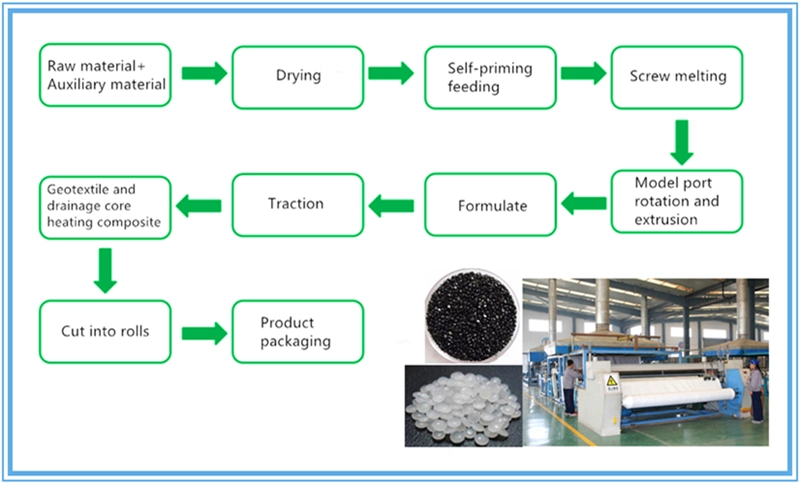

How is Composite Geodrainage Net Produced?

The production process of a composite drainage net usually includes the following steps:

(1)raw material preparation: prepare the original production of geodrainage net and auxiliary materials after adding drying, and then on the double rod melting equipment after melting extrusion, finalize the set cooling output geodrainage net, that is, the core of the composite drainage net;

(2)prepare geotextile: if it is a single-layer composite drainage net, use a roll of geotextile, if it is a double composite geotextile drainage net, you need to have two rolls of geotextile;

(3)composite molding: the geotextile and drainage core layer is compounded, the drainage core layer is covered in one or both sides of the geotextile, and it is firmly bonded together by heating and pressing.

(4)cutting and finishing: according to the design requirements and customer needs, cut and finish the composite drainage net, so that it can reach the required size and specifications.

(5)quality inspection: quality inspection of the composite drainage net produced, including checking the size, thickness, drainage performance, connection firmness and other parameters to meet the standards and requirements.

(6)packaging and storage: the qualified composite drainage net is stored in the warehouse after packaging, waiting for delivery or use.

Strict quality control and compliance with relevant standards in the production process are important links to ensure the stable performance of the composite drainage net.

Company Advantages

Expertise and Innovation: Established in 2008, Haoyang Environmental Co., Ltd. boasts over a decade of experience in geosynthetic material research, development, and manufacturing. Our professional technical R&D team continuously innovates to provide state-of-the-art solutions for environmental challenges.

Quality Certifications: Our company is certified with ISO 9001, ISO 14001, and OHSAS 18001, reflecting our commitment to quality management, environmental sustainability, and occupational health and safety. We also hold the CQC environmental product certification.

Recognition and Patents: Recognized by the National Laboratory as the "Shandong Enterprise Technology Center" and the "Environmental Protection New Materials Engineering Laboratory," Haoyang has secured three invention patents and 32 utility model patents, along with two provincial-level scientific and technological achievement certifications.

Comprehensive Services: From environmental engineering consulting and design to construction, soil remediation, and solid waste treatment, Haoyang offers a full spectrum of services to meet diverse client needs.

Production Workshop

Welcome to our advanced production workshop! This is the center of precision manufacturing in our company. The following are some pictures of our advanced production equipment and high-quality products, as well as the workshop pictures implemented in accordance with the 6S standard: the equipment floor is clean, the product equipment is placed reasonably, and the ground line is clear and clear.

These pictures show our company's production equipment and some of our products, demonstrating our advanced production process and precision manufacturing capabilities.

|  |

|  |

Comparison of Different Standards of Composite Drainage Net

This comparison is to compare two kinds of composite drainage networks under different standard rules, and explore their differences in carbon black content, flexion strength, water conductivity, density and other aspects. Through the discussion of these two standard rules, we can deeply analyze and compare the composite drainage network, and we can understand their characteristics, advantages and limitations more comprehensively.

No. | Item | Unit | Execution standard | ||

CJ/T 452-2014 | JT T1087.1-2016 | ||||

1 | Width deviation | % | ≧-0.5 | ≧-1.0 | |

2 | Thickness limit deviation | % | ≧0 | ≧0 | |

3 | Density | g/cm3 | ≧0.939 | ≧0.94 | |

4 | Carbon black content | % | 2-3 | ≧2 | |

5 | Longitudinal tensile strength | Kn/m | Drainage net core | ≧8 | 8-14 |

Composite drainage net | ≧16 | 16-22 | |||

6 | Longitudinal water conductivity | m2/s | Drainage net core | ≧3.0*10-3 | ≧(3.0-5.0)*10-3 |

Composite drainage net | ≧3.0*10-4 | ≧(3.0-5.0)*10-4 | |||

7 | Peel strength | Kn/m | ≧0.17 | ≧0.17 | |

8 | Unit weight of geotextile | g/m2 | ≧200 | - | |

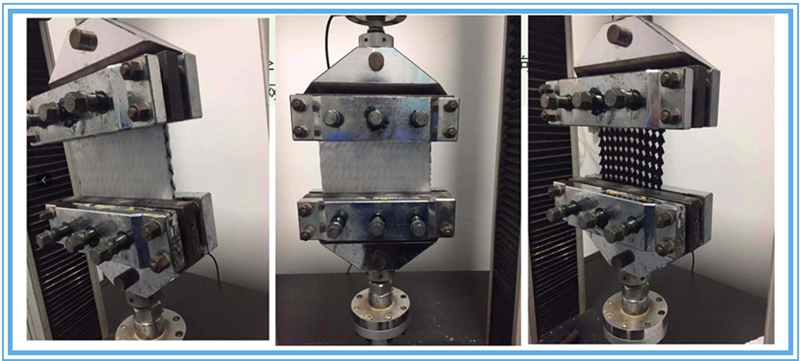

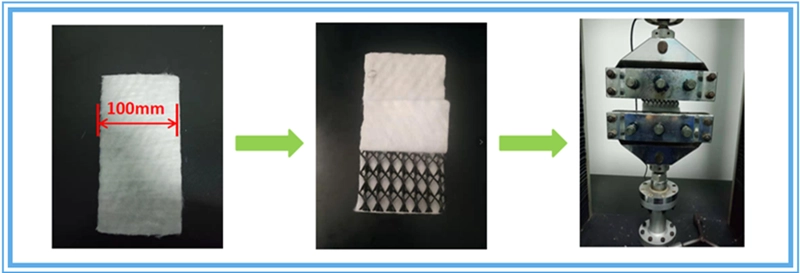

Test Experiment Procedure:

The Role of 3D composite Geodrainage Net

(1)laid between the foundation and the base, used to discharge the water between the foundation and the base, capillary water and effectively combined into the edge drainage system. This structure automatically shortens the drainage path of the foundation, greatly reduces the drainage time, and can reduce the use of selected foundation materials, which can extend the service life of the road.

(2)laying three-dimensional composite drainage net on the base can prevent the base fine material from entering the base, that is, playing an isolation role. The aggregate base will enter the upper part of the geonet to a limited extent. In this way, the composite geotechnical drainage net also has a potential role in limiting the lateral movement of the aggregate base, in this way, its role is similar to the reinforcement of the geogridging. In general, the tensile strength and rigidity of the composite geodrainage net are better than many geogates used for foundation reinforcement, and this limiting effect will improve the supporting capacity of the foundation.

3D Composite Geodrainage Net Advantages

(1)Powerful drainage function: the integrated drainage core layer can effectively remove the water inside the soil, reduce the water pressure in the soil, and prevent the adverse effects caused by soil liquefaction and water retention.

(2)Excellent isolation and protection function: combined with the isolation performance of geotextile or geomembrane, effectively prevent the mixing between different soil layers and protect the base and superstructure.

(3)Improve soil stability: By promoting water flow and reducing the amount of liquid water in the soil, it helps to improve the stability and carrying capacity of the soil.

(4)Flexibility and wide applicability: According to different engineering needs and geological conditions, different material and structure combinations can be selected for various engineering scenarios.

(5)Convenient construction: easy installation, can be prefabricated or laid on site, saving construction time and labor costs.

(6)Environmentally friendly: The use of environmentally friendly materials, less impact on the surrounding environment, help to protect the natural ecology.

In summary, the 3D composite geodrainage net integrates drainage, isolation and protection functions in one, providing a comprehensive soil protection and drainage solution, suitable for a variety of civil engineering projects.

Construction Process of 3D Composite Geotechnical Drainage Net

First, ground preparation

Construction environment inspection: Before the drainage net is laid, the ground must be cleaned and removed of debris to ensure that the ground is flat, without adhesion and oil; Check the construction environment to ensure that the construction area is dry and smooth, and that there are no sharp objects or sharp surfaces that may damage the drainage net.

Preparation before construction: prepare the necessary drainage net materials and tools according to the design requirements and construction drawings; Next, it is necessary to carry out the preparatory work such as elevation positioning, pile foundation setting and excavation of dredging hidden pipe. Also ensure that the construction personnel have the relevant skills and experience.

Second, drainage pipe installation

The next step is to install the drainage pipe. In the installation process, special attention needs to be paid to the details of the slope, connection and flushing of the drainage pipe. After installation, static pressure test and leakage test are also required to ensure installation quality.

Third, three-dimensional composite drainage net laying rules

The core part of the whole construction is the laying of 3D geotechnical composite drainage net. During the laying process, it is necessary to pay attention to the expansion and docking of the grid to ensure that there is no wrinkle and net leakage at the splicing place, and to ensure that the net surface is stable and smooth. Strictly follow the following rules:

(1) The 3D geotechnical composite drainage net shall be laid in strict accordance with the geotechnical composite material layout design on the tender;

(2) The equipment for the construction of 3D geocomposite drainage net cannot work on the geosynthetic materials that have been laid. When paving the 3D geotechnical composite drainage net, the outdoor air temperature can not be lower than -5 degrees or higher than 40 degrees;

(3) All exposed 3D geocomposite drainage net edges must be pressed with sandbags or other heavy objects. In this way, the geotechnical composite drainage net can avoid being blown up by the wind and pulled out of the surrounding anchoring ditch. It is necessary to avoid the deployment of geotechnical composite drainage net in strong winds to prevent wind blowing;

(4) The laying, pulling, lifting or rolling of the 3D geocomposite drainage net must be controlled, and some uncontrolled expansion methods such as "free fall" are not allowed, and the laying method must ensure that the geocomposite drainage net and any other underlying geomaterials are not damaged;

(5) The layout of the 3D geotechnical composite drainage net must ensure that it will not cause folding or folding of the geotechnical composite drainage net or the direct geotechnical materials below, which will cause the arch of the geotechnical materials;

(6) Construction personnel should protect the geotechnical materials that have been laid to avoid damage that may be caused by construction machines. Any damage to 3D geocomposites or other geocomposites made for the above reasons must be repaired;

(7) When the 3D geotechnical composite drainage net is placed on the slope with a slope slope greater than 10%, the slope direction should be minimized to reduce the number of transverse overlap, and all 3D geotechnical composite drainage nets must be at least 1.5 meters above the slope foot;

(8) During the construction of 3D composite geotechnical drainage net, there should be no damage to the underlying geotechnical materials or things blocking the drainage net, such as mud, dust, dirt and debris;

(9) After the construction of the 3D geotechnical composite drainage net, the construction personnel and engineers must conduct a thorough inspection to ensure that there are no sharp things that damage the geotechnical material under the composite drainage net to cause damage or defective joints.

Fourth, joint treatment

Once the 3D geocomposite drainage net is laid, the joint needs to be treated. The joints need to be cut and reinforced to ensure sealing and firmness. The specific joint treatment method will vary depending on the material and specifications.

Fifth, construction records

Record important construction details, such as connection points, fixed positions, cut dimensions, etc., to assist in post-construction inspection and maintenance.

Sixth, surface dressing

Finally, it is necessary to finish the surface of the 3D geocomposite drainage net. The cleaning and finishing work is aimed at making it look flat and beautiful. You can choose to spray the surface layer or directly apply the protective layer method to finish the surface.

Seventh, quality acceptance

After the drainage net is laid, a comprehensive quality acceptance is carried out to check whether the connection, fixing and flatness of the drainage net meet the requirements.

Construction Site Display

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

219908.webp)

261401.webp)

Mode of Transport

We provide our customers with a variety of transportation methods for remote delivery of geomaterials, ensuring that products reach their destinations safely and quickly. Our range of transport options includes land, sea and air transport to meet the different needs and project requirements of our customers.

FAQ

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

Experience the unparalleled performance and environmental benefits of the White and Green Mountain Protection Special Composite Drainage Net. For more information and inquiries, please contact us.

Partner with Haoyang Environmental Co., Ltd. for innovative and sustainable solutions tailored to your environmental engineering needs.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

483.webp)

214.webp)

934.webp)