White Waterproof Geotextile Fabric for Tunnel

White waterproof filament non-woven geotextiles are essential materials used in tunnel construction for effective water management and structural integrity. These high-performance geotextiles are made from continuous filament polyester or polypropylene fibers, providing excellent waterproofing, filtration, and drainage properties. They play a crucial role in protecting tunnels from water ingress, enhancing durability, and maintaining safety standards. In this article, we will delve into the key features, specifications, applications, and benefits of using white waterproof filament non-woven geotextiles in tunnel projects.

Geotextile, also known as geotextile or geofiber, is a multi-layer fabric, usually made of materials such as polyester, polypropylene or polyethylene, and comes in two basic forms: woven (similar to sacks) and nonwoven (similar to plush). With excellent water permeability and filterability, it can protect the soil and slow down soil erosion, while also increasing the stability and carrying capacity of the soil. Often used in roads, railways, embankments and other projects as a reinforcement and protection of soil barrier, with the ability to separate, filter, strengthen, protect or drain. Nowadays, more and more geotextile derivatives such as floor, impermeable layer, floor, geotextile pipe can be beneficial in geological and environmental engineering design.

Haoyang Environmental Co., Ltd. is specialized in the production of geotextile manufacturers, filament non-woven geotextile is one of our main products, is the south to north water diversion project supplier.

Specifications of White Waterproof Filament Non-Woven Geotextile

The following table outlines the typical specifications for white waterproof filament non-woven geotextiles used in tunnel applications:

| Specification | Details |

|---|---|

| Material | Polyester or Polypropylene Continuous Filament |

| Color | White |

| Thickness | 1.0 mm to 5.0 mm |

| Weight | 150 g/m² to 800 g/m² |

| Tensile Strength | ≥ 20 kN/m |

| Elongation at Break | ≥ 50% |

| Water Permeability | 5 × 10⁻⁴ to 5 × 10⁻³ cm/s |

| Puncture Resistance | ≥ 500 N |

| UV Resistance | > 90% retention of strength after 500 hours of exposure |

| Roll Width | 1 m to 6 m |

| Roll Length | 50 m to 100 m |

| Melting Point | 165°C to 260°C |

| Chemical Resistance | Resistant to alkalis, acids, and organic solvents |

| Temperature Range | -30°C to 80°C |

| Standards | ASTM D5261, EN ISO 10319, ISO 9001 |

TABLE OF CONTENTS

White Waterproof Geotextile Fabric Features

White Waterproof Geotextile Fabric Application

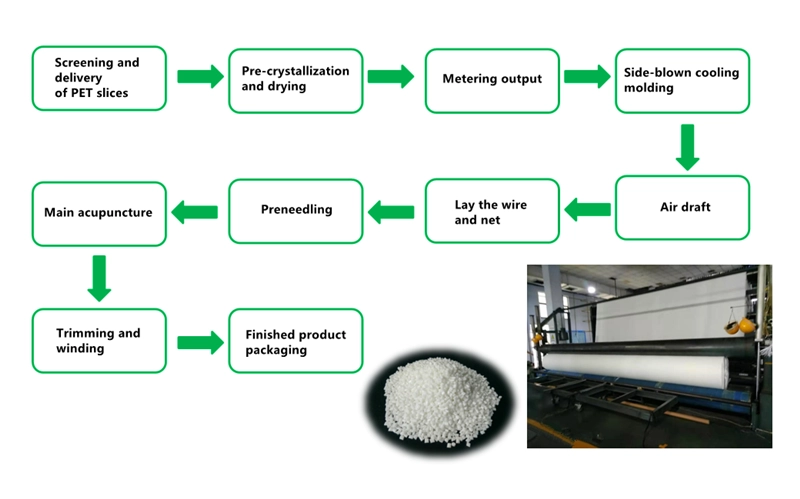

How is Haoyang Filament Geotextile Produced?

Technical Data Sheet of Polyester Geotextile GBT17639-2008

Comparison of Acid-alkali Resistance of Filament Geotextile

White Waterproof Geotextile Fabric Features

1. Uv resistance, acid and alkali resistance.

2. High temperature resistance up to 230℃, maintain structural stability and original physical properties.

3. High strength tear resistance.

4. Resistance to erosion by chemical substances in the soil.

5. It has a high elongation rate, which can adapt to uneven and irregular substrates.

White Waterproof Geotextile Fabric Application

1. Water conservancy and hydropower engineering.

2. Paving roads and railways.

3. Airports and ports.

4. River protection and tunnel.

5. Environmental protection, etc.

How is Haoyang Filament Geotextile Produced?

Filament is one of the important raw materials for geotextile manufacturing, and its production process goes through multiple links of precision processing and treatment to ensure that the final product has the required strength, durability and stability. The following diagram will show the filament production process, detailing the conversion process from polymer particles to formed fibers. The high-quality preparation of filament has an important impact on the quality and performance of geotextiles, so our company has introduced a number of advanced production equipment for the quality of filament products to improve and upgrade. Take an in-depth look at the filament production process and its key role in geotextile manufacturing.

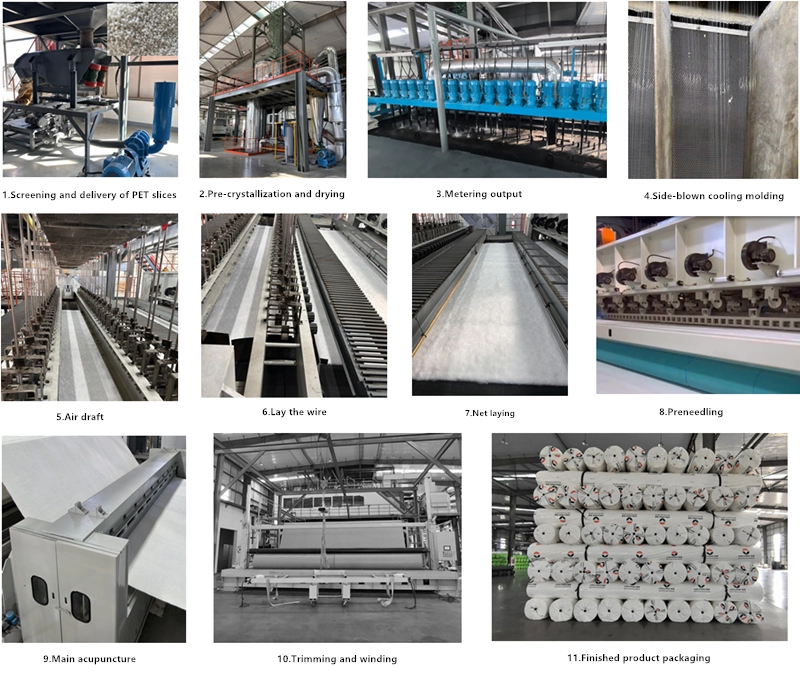

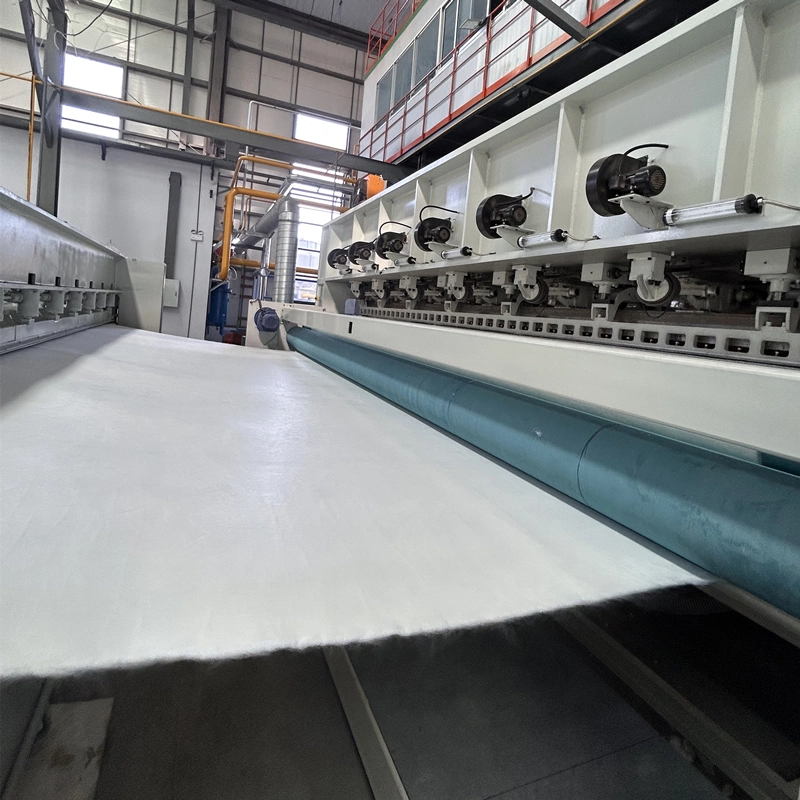

Factory Display

We sincerely welcome you to our filament geotextile production workshop. As one of the leading producers of geomaterials, we are committed to providing high quality, innovative and reliable geomaterials to meet a wide range of engineering and construction needs.

Our filament geotextile workshop is a modern and efficient production base. State-of-the-art facilities, using the latest technology and production processes to ensure excellent quality and consistency of products.

154069.webp)

552318.webp)

361305.webp)

301087.webp)

Technical Data Sheet of Polyester Geotextile GBT17639-2008

The data in the National standard form is based on the results of professional testing and specification development and represents the key performance, quality standards or technical requirements of the products or services in the industry. This data typically includes a variety of indicators, parameters, and specifications that are used to assess the safety, reliability, and conformity of the product.

Our company's products are strictly in accordance with the national standard or even beyond the national standard for production and manufacturing, quality control standards are higher than the national standard, our each batch of products have passed the strict laboratory instrument testing before they will be sold.

Item | Unit | Index | |||||||||

Nominal breaking strength | Kn/m | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | |

1 | Longitudinal and transverse fracture strength | Kn/m | ≥4.5 | ≥7.5 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 |

2 | Vertical and horizontal standard strength corresponds to elongation | % | 40~80 | ||||||||

3 | CBR bursting strength(Kn/m) | Kn/m | ≥0.8 | ≥1.6 | ≥1.9 | ≥2.9 | ≥3.9 | ≥5.3 | ≥6.4 | ≥7.9 | ≥8.5 |

4 | Vertical and horizontal tearing strength | Kn | ≥0.14 | ≥0.21 | ≥0.28 | ≥0.42 | ≥0.56 | ≥0.7 | ≥0.82 | ≥1.1 | ≥1.25 |

5 | Equivalent aperture O90(o95) | mm | 0.05~0.20 | ||||||||

6 | Vertical permeability coefficient | cm/s | K*(10-1~10-3) K=1.0~9.9 | ||||||||

7 | Thickness | mm | ≥0.8 | ≥1.2 | ≥1.6 | ≥2.2 | ≥2.8 | ≥3.4 | ≥4.2 | ≥5.5 | ≥6.8 |

8 | Amplitude deviation | % | -0.5 | ||||||||

9 | Mass deviation per unit area | % | -5 | ||||||||

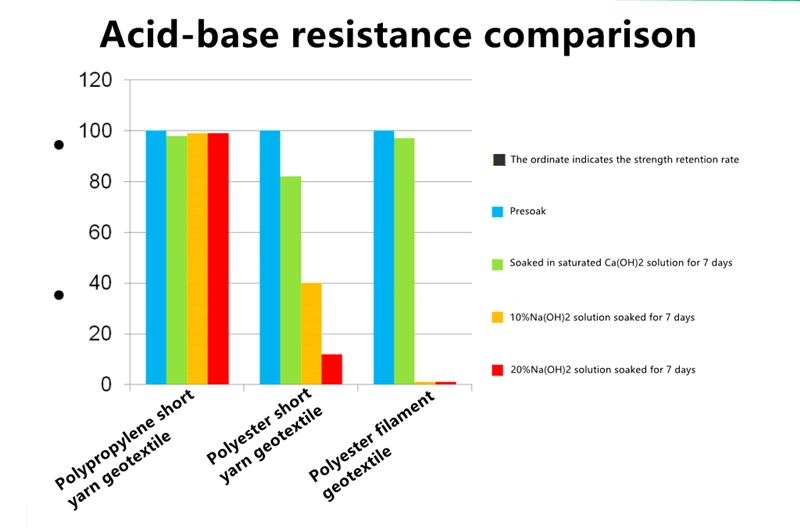

Comparison of Acid-alkali Resistance of Filament Geotextile

Filament is one of the important components of geotextile, and its acid-alkali resistance plays a key role in engineering applications. The comparison diagram below shows how filaments and filaments behave in different concentrations of acidic and alkaline environments. The chemical resistance of the filament has an important impact on the stability and durability of geotextiles in various engineering projects. With this comparison diagram, we are able to gain a clearer understanding of how filaments behave in acid-base environments, so that we can better select materials suitable for specific engineering needs.

Project Construction Photo

Below are photos of the construction site of our project, showing the key stages of the construction process, the operations of the workers, and the actual conditions of the site environment. These photos truly reflect and record the progress of the project, the quality of the engineering, the implementation of safety measures and the teamwork. They are an important tool for project management and supervision, helping to track project progress and assess construction quality.

331772.webp)

616041.webp)

White waterproof filament non-woven geotextiles are essential components in tunnel construction projects, offering exceptional waterproofing, filtration, and drainage capabilities. With their high strength, chemical resistance, and adaptability, they provide a reliable solution for enhancing tunnel durability and safety. By adhering to stringent manufacturing standards and being available in various specifications, these geotextiles meet the diverse needs of modern infrastructure projects. For more information on pricing, customization options, and detailed specifications, it is recommended to consult with reputable suppliers or manufacturers.

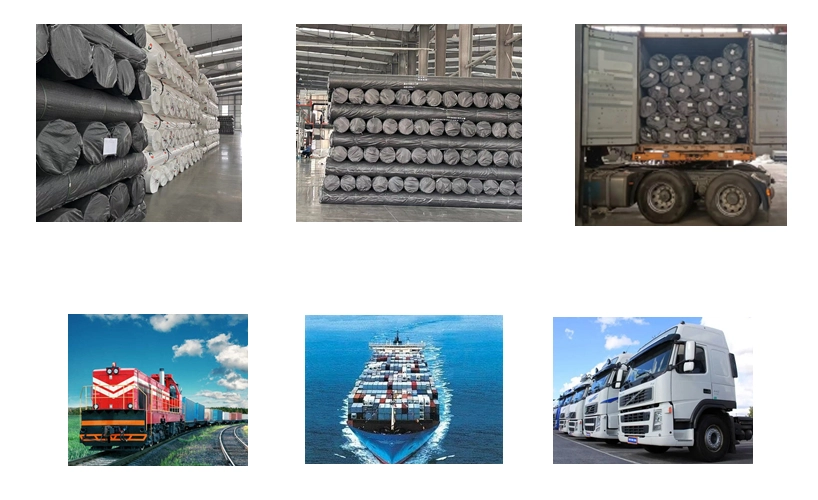

Mode of Transport

Frequently Asked Questions

Q: Are you a factory or a trading company?

A: We are a professional manufacturer of geomembrane, geotextile, composite geomembrane, etc., with ISO9001 quality management system certification.

Q: Where is your factory located? How do I get there?

A: Our factory is located in Yucheng High-tech Development Zone, Dezhou City, Shandong Province. You can take a plane to Jinan Yaoqiang International Airport, and then we will pick you up.

Q: Could you please send the sample before confirming the order?

A: Yes, we'd be happy to send you a free sample for evaluation if you'd like.

Q: What is the lead time?

A: Usually 5-10 working days after receiving the deposit.

Q: Can you produce according to the customer's requirements?

A: Of course. We are professional manufacturers. OEM and ODM are welcome.

Q: How do you guarantee the quality testing of your products?

A: The testing center of Haoyang Environmental Co., Ltd. obtained the CNAS Laboratory accreditation Certificate, certificate number L11088. Each batch of products will undergo rigorous testing before leaving the factory.

![]() 200g Staple fiber non-woven geotextile.pdf

200g Staple fiber non-woven geotextile.pdf

![]() 300g PET geotextiles test report.pdf

300g PET geotextiles test report.pdf

503.webp)

759.webp)

597.webp)

411.webp)