Coastal protection is a critical aspect of geotechnical engineering, aiming to safeguard shorelines from erosion, wave action, and other environmental factors. Woven geotextile fabric has proven to be an effective and versatile material for coastal protection projects. If we want to know why we should choose woven geotextiles for coastal protection, we must first understand what woven geotextiles are, the performance characteristics and main applications of woven geotextiles.

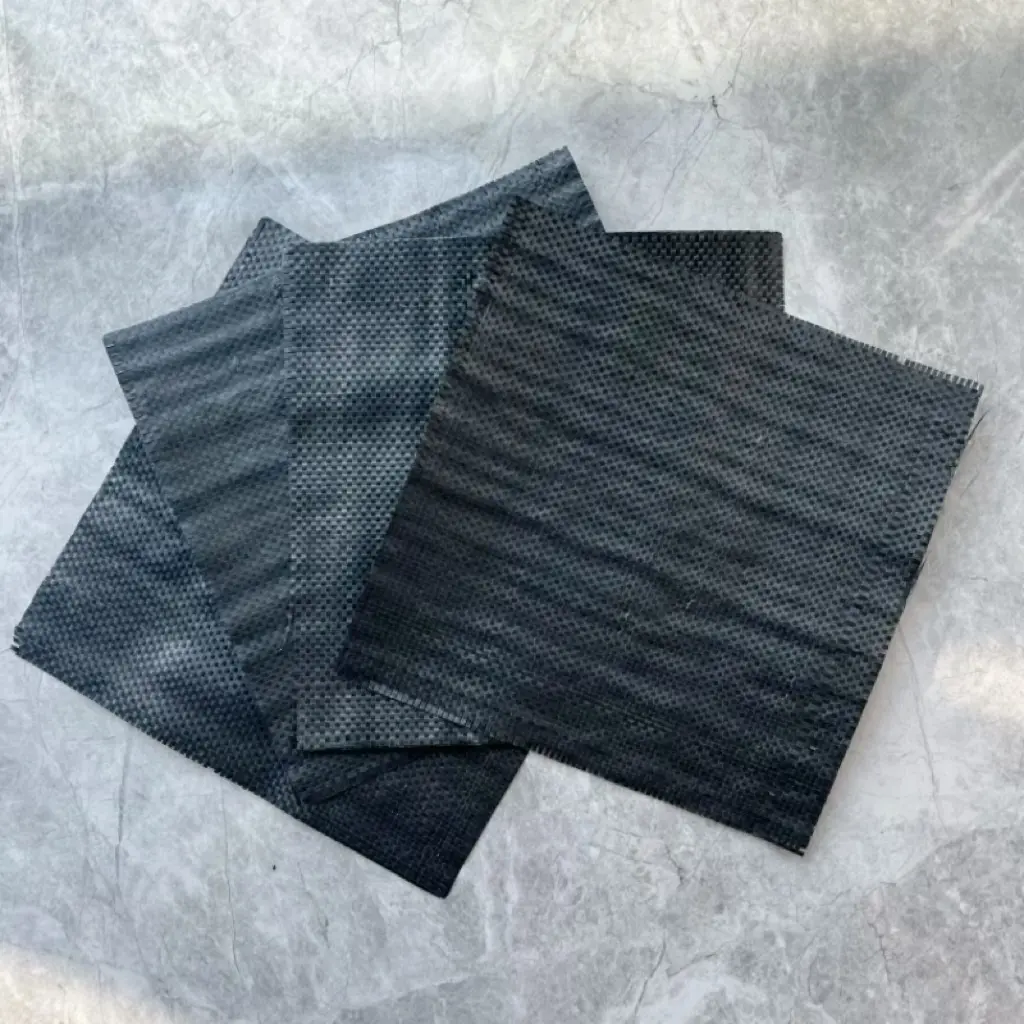

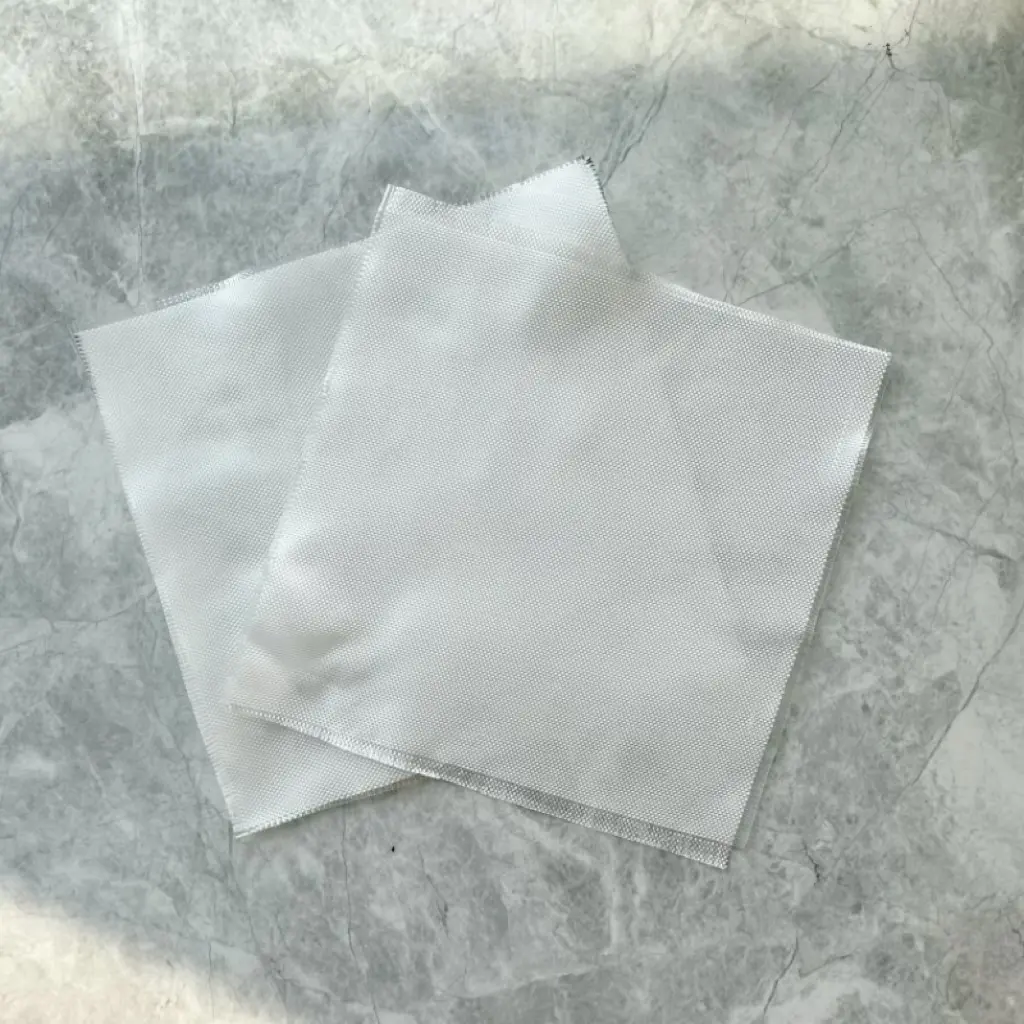

What is woven geotextile

Woven geotextile is made from polypropylene and polyethylene flat yarns. It consists of two sets of parallel yarns (in flat shape), with one set arranged longitudinally (in the direction of fabric movement), called warp yarns, and the other set arranged transversely as weft yarns. Using different weaving equipment and techniques, the warp and weft yarns are interlaced to form a fabric. The thickness and density of the fabric can be adjusted according to different applications. Generally, woven geotextiles are relatively thin and exhibit considerable tensile strength in both the warp and weft directions (greater in the warp direction). They possess excellent stability properties and are widely used in hydraulic engineering, power plant projects, highway engineering, aviation engineering, and railway engineering.

Performance features of woven geotextile

1, Reinforcement function: Used in rock engineering such as highways, railways, airports, stone dams, breakwaters, backfilling of retaining walls, slopes, etc., to disperse soil stress, increase soil modulus, limit soil slippage, and improve stability.

2, Protection function: Prevents erosion of embankments by wind, waves, tides, rain, and is used for revetment, slope protection, bottom protection to prevent soil erosion.

3, Filtration function: Used as a filter layer for dikes, dams, rivers, coastal rocks, soil slopes, retaining walls, preventing sand particles from passing through while allowing water or air to pass freely.

Main applications

1, Road Construction: Used in road construction projects for reinforcement and stabilization of subgrade soils, preventing soil erosion, and improving the longevity and performance of road surfaces.

2, Railway Engineering: Employed in railway engineering for stabilizing subgrade soils, preventing track deformation, enhancing load-bearing capacity, and providing erosion control along railway embankments.

3, Coastal and Hydraulic Engineering: Used in coastal protection and hydraulic engineering projects to prevent erosion of embankments, shorelines, and riverbanks by waves, currents, and tides, as well as for the construction of revetments and breakwaters.

4, Retaining Walls and Slope Stabilization: Utilized in the construction of retaining walls and for slope stabilization to reinforce soil structures, prevent soil erosion, and enhance stability in steep terrain.

5, Landfill and Environmental Protection: Applied in landfill engineering for liner systems to prevent leakage of contaminants into the surrounding environment, as well as in environmental protection projects for erosion control, sediment filtration, and soil stabilization.

6, Water Management and Drainage: Used in drainage systems, such as French drains and trench drains, to facilitate water flow while preventing soil loss and clogging of drainage pipes.

7, Mining and Quarrying: Employed in mining and quarrying operations for soil stabilization, erosion control, and slope reinforcement to mitigate environmental impacts and ensure safe working conditions.

8, Landscaping and Horticulture: Utilized in landscaping and horticultural applications for weed control, soil separation, and erosion prevention in gardens, parks, and green spaces. These applications highlight the versatility and effectiveness of flat wire woven geotextiles in various civil engineering, environmental, and landscaping projects.

Why choose woven geotextile fabric for coastal protection?

Woven geotextile fabric stands out as a preferred option for coastal protection due to its multitude of advantages:

1, Strength and Durability: These fabrics boast high tensile strength and remarkable durability, enabling them to withstand the harsh conditions prevalent in coastal regions. They effectively endure the impact of wave action, tidal forces, and erosion, providing reliable long-term protection.

2, Permeability: A key attribute of woven geotextiles is their ability to permit water flow while retaining soil particles. This feature promotes efficient drainage, thereby reducing hydrostatic pressure behind coastal structures. Effective drainage is essential for maintaining stability and preventing erosion-induced damage.

3, Soil Stabilization: Woven geotextiles play a crucial role in stabilizing soil by offering a firm foundation and reinforcing its structure. This prevents soil movement and erosion, addressing critical concerns, especially in coastal areas where erosion can lead to land loss and compromise structural integrity.

4, Versatility: With a wide range of strengths, sizes, and configurations available, woven geotextiles offer versatility in addressing the unique requirements of coastal protection projects. They can be employed in various applications, including revetments, embankments, breakwaters, and shoreline stabilization, providing tailored solutions for diverse coastal environments.

5, Cost-Effectiveness: Despite their exceptional performance, woven geotextiles are often more cost-effective than traditional coastal protection methods such as concrete structures or rock armor. Their installation typically requires less labor and machinery, and they offer long-term performance with minimal maintenance needs, resulting in significant cost savings over time.

In summary, the combination of strength, permeability, soil stabilization capabilities, versatility, and cost-effectiveness makes woven geotextile fabric an increasingly popular and effective choice for coastal protection projects worldwide.

Constructon attentions

441537.webp)

When using woven geotextile fabric in construction, several key considerations should be taken into account to ensure its effectiveness and longevity:

1, Proper Installation: Ensure that the geotextile is installed correctly according to the project specifications and manufacturer guidelines. This includes proper positioning, alignment, and overlap of fabric rolls to prevent gaps or uneven coverage.

2, Site Preparation: Prepare the site adequately before installing the geotextile fabric. This may involve grading, compacting the soil, and removing any debris or vegetation that could compromise the fabric's performance.

3, Selection of Appropriate Fabric: Choose the right type and specification of woven geotextile fabric based on the specific requirements of the project, including strength, permeability, and durability. Consider factors such as soil type, slope gradient, and expected loads or stresses.4,

4, Protection During Installation: Take precautions to protect the geotextile fabric from damage during installation. Avoid sharp objects, heavy equipment, or excessive traffic on the fabric, which could cause tearing or puncturing.

5, Overlap and Seaming: Ensure proper overlap and seaming of adjacent fabric panels to create a continuous barrier. Use appropriate seaming techniques such as sewing or heat sealing to achieve strong and durable connections.

6, Anchoring and Securing: Secure the geotextile fabric in place using appropriate anchoring methods such as stakes, pins, or weights. This helps prevent movement or displacement of the fabric, especially in areas prone to high winds or water flow.

7, Compatibility with Other Materials: Ensure compatibility between the geotextile fabric and other construction materials used in the project, such as soil, aggregates, or drainage systems. Avoid chemical reactions or degradation that could compromise the integrity of the fabric.

8, Monitoring and Maintenance: Regularly inspect the geotextile fabric after installation and during the lifespan of the project. Address any signs of damage, degradation, or inadequate performance promptly to prevent further issues and ensure the long-term effectiveness of the fabric.

FAQ

1, What are the primary benefits of using woven geotextile fabric for coastal protection?

Woven geotextile fabric offers superior strength and durability, effectively withstanding the harsh conditions found in coastal environments such as wave action, tidal forces, and erosion.

2, How does woven geotextile fabric contribute to coastal erosion control?

Woven geotextile fabric promotes effective drainage while retaining soil particles, reducing hydrostatic pressure behind coastal structures and helping to stabilize the soil, thereby preventing erosion.

3, What factors should be considered when selecting woven geotextile fabric for coastal protection projects?

When choosing woven geotextile fabric for coastal protection, it's important to consider factors such as strength, permeability, durability, and compatibility with other materials to ensure optimal performance in specific coastal environments.

4, Can woven geotextile fabric be customized for different coastal protection needs?

Yes, woven geotextile fabric can be customized in terms of strength, size, and configuration to meet the specific requirements of various coastal protection applications, including revetments, embankments, breakwaters, and shoreline stabilization.

5, What long-term cost-saving benefits does woven geotextile fabric offer for coastal protection projects?

Despite its high performance, woven geotextile fabric is often more cost-effective than traditional coastal protection methods. It requires less labor and machinery for installation and offers long-term durability with minimal maintenance needs, resulting in significant cost savings over time.

897.webp)

942.webp)

237.webp)