What is Woven geotextile?

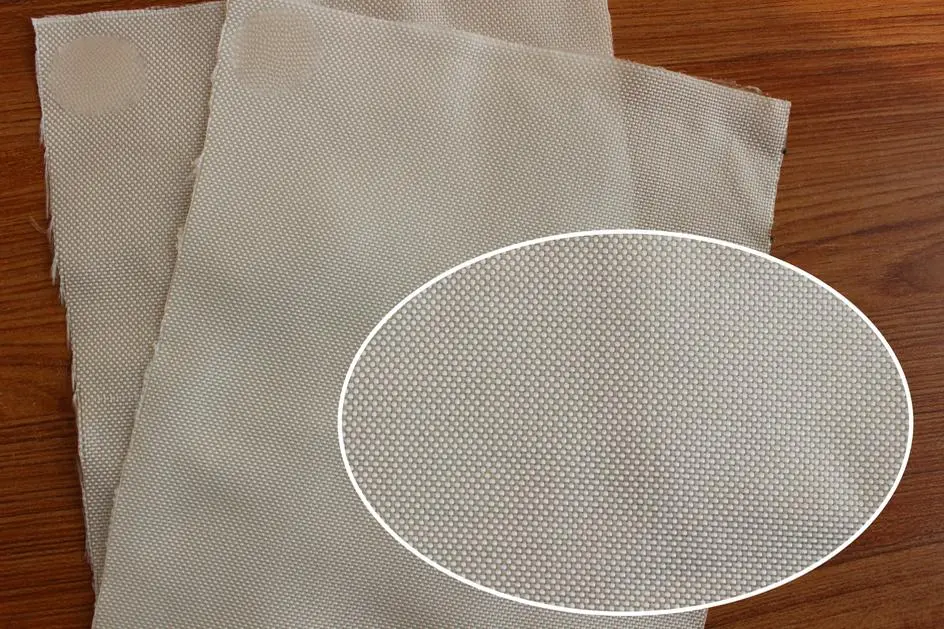

Woven geotextile refers to a type of geotextile made by weaving individual polymeric yarns (such as polyester or polypropylene) together using specialized weaving machinery. The weaving process creates a strong, durable, and dimensionally stable fabric with uniform openings or pores between the yarns.

These geotextiles are used in various civil engineering and construction applications due to their excellent strength, filtration, separation, and reinforcement properties. They are commonly utilized for:

Separation: Used between different layers of soil, aggregate, or other materials to prevent mixing and maintain the integrity of each layer.

Filtration: Allows water to pass through while preventing soil particles from migrating, thereby preventing clogging and maintaining soil stability.

Reinforcement: Provides support by improving the tensile strength of soils or other materials in road construction, embankments, retaining walls, etc.

Erosion Control: Helps prevent soil erosion by stabilizing soil surfaces and allowing water to drain through while retaining soil particles.

Woven geotextiles are available in various strengths, sizes, and pore sizes, allowing them to be tailored to specific project requirements. Their robust structure and versatility make them valuable components in many civil engineering and environmental projects.

Item | Details |

Model No. | PP Woven Geotextile |

Material | PP |

Kind | Woven |

Length | As per your request |

Width | 1-8 meters |

Hot Iron | As per your request |

Before Sales Service | Technical Data Sheet/Free Sample |

Unit Weight | 80gsm - 1000gsm |

Certificate | ISO9001/14001 |

Structure | Fabric Form |

Project Solution Capability | Total Solution for Projects |

Model Number | |

Keyword | PP Woven Geotextile |

Name | Woven Geotextile |

Design Style | Traditional |

Advantage | High Density |

Transport Package | Woven Geotextile |

Specification | 100gsm, 150gsm, 200gsm, 250gsm, 300gsm, 800gsm, 1000gsm |

Trademark | Zhongloo |

Origin | China |

HS Code | 5603139000 |

Production Capacity | 60,000 square meters per day |

What is Non-woven geotextiles?

Non-woven geotextiles are engineered fabrics manufactured by bonding or interlocking fibers together using mechanical, thermal, or chemical processes without weaving. These fabrics are made from synthetic polymers such as polypropylene, polyester, or polyethylene.

Non-woven geotextiles possess several characteristics and functions that make them suitable for various civil engineering and environmental applications:

Filtration: They allow water to pass through while preventing the loss of soil or other materials, effectively acting as filters.

Separation: Used to separate different soil layers or materials, preventing intermixing and maintaining the structural integrity of each layer.

Drainage: Facilitates water flow while preventing the clogging of drainage systems.

Erosion Control: Helps in preventing soil erosion by stabilizing surfaces and maintaining soil integrity.

Reinforcement: Provides support by enhancing the tensile strength of soils or other materials.

Non-woven geotextiles come in various thicknesses, weights, and strengths to suit specific project requirements. They are cost-effective, easy to install, and adaptable to different environmental conditions, making them widely used in road construction, drainage systems, landscaping, erosion control, and other civil engineering applications.

HS Code | 5603139000 |

No. | Item | Specification | Note |

1 | Weight Variation % | -8 -8 -8 -8 -7 -7 -7 -7 -6 -6 -6 | - |

2 | Thickness mm ≥ | 0.9 1.3 1.7 2.1 2.4 2.7 3.0 3.3 3.6 4.1 5.0 | - |

3 | Width Variation % | -0.5 | - |

4 | Breaking Strength KN/m | 2.5 4.5 6.5 8.0 9.5 11.0 12.5 14.0 16.0 19.0 25.0 | MD and TD |

5 | Elongation at Break % | 25 ~ 100 | - |

6 | CBR Mullen Burst Strength KN ≥ | 0.3 0.6 0.9 1.2 1.5 1.8 2.1 2.4 2.7 3.2 4.0 | - |

7 | Sieve Size 090 mm | 0.07 ~ 0.2 | - |

8 | Vertical Permeability Coefficient cm/s | K× (0.1 ~ 0.001) | k=1.0-9.9 |

9 | Tear Strength KN ≥ | 0.08 0.12 0.16 0.20 0.24 0.28 0.33 0.38 0.42 0.46 0.6 | MD and TD |

Woven vs non-woven geotextile

Structural differences

Woven geotextile: This type of geotextile is formed by interweaving fiber yarns, similar to cloth, with a clear yarn structure that facilitates water flow and soil filtration. Its high strength and rigidity make it suitable for engineering projects that require higher load-bearing capacity.

Non-woven geotextile: This geotextile is an irregular structure formed by weaving or bonding fibers together, with a uniform appearance and good permeability. Due to its higher flexibility and better permeability, it is suitable for projects requiring better water flow and soil filtration.

Differences in application areas

Application scenarios of woven geotextile: Due to its high strength and rigidity, it is suitable for engineering projects that require separation, filtration and reinforcement. For example, it is widely used in road construction, retaining walls and soil stabilization.

Application scenarios of non-woven geotextile: Its good permeability and filtration function make it excellent in projects that require better drainage, soil protection and erosion prevention. Areas such as landfills, underground drainage and erosion prevention projects.

Advantages and Disadvantages

Woven geotextiles and non-woven geotextiles have distinct characteristics, each with its own advantages and disadvantages:

Advantages of Woven Geotextiles:

Strength and Durability: Woven geotextiles are generally stronger and more durable due to their weaving process, making them suitable for applications requiring higher tensile strength.

Permeability: They offer good water permeability while providing adequate filtration, allowing water to pass through while restricting the movement of soil particles.

Dimensional Stability: Woven geotextiles maintain their dimensional stability, resisting stretching and distortion during installation or under load.

High Load Bearing Capacity: Their structural integrity and high tensile strength make them suitable for applications requiring reinforcement and load distribution, such as road stabilization.

Disadvantages of Woven Geotextiles:

Less Puncture Resistance: Compared to non-woven geotextiles, woven fabrics may have lower resistance to puncture due to the presence of larger openings between the yarns.

Reduced Conformability: Woven geotextiles may be less conformable to irregular surfaces or terrain due to their inherent rigidity from the woven structure.

Advantages of Non-Woven Geotextiles:

Excellent Filtration and Drainage: Non-woven geotextiles provide excellent filtration while offering good water flow and drainage capabilities.

High Porosity: They have a uniform structure with smaller pore sizes, enhancing their filtration properties and reducing the risk of clogging.

Flexible and Conformable: Non-woven geotextiles conform well to irregular surfaces, making them suitable for various terrain types and shapes.

Cost-Effectiveness: Often more cost-effective than woven geotextiles, especially in applications where high tensile strength isn't the primary requirement.

Disadvantages of Non-Woven Geotextiles:

Lower Tensile Strength: Generally, non-woven geotextiles have lower tensile strength compared to woven geotextiles, making them less suitable for applications requiring high loads or reinforcement.

Reduced Longevity: They may have a shorter lifespan in applications subjected to high loads or mechanical stress due to their lower tensile strength.

Choosing between woven and non-woven geotextiles depends on the specific requirements of the project, including factors such as strength, permeability, terrain, installation method, and budget constraints. Both types have their own distinct advantages and are selected based on their suitability for the intended application.

How to choose?

When undertaking a project, the choice of which type of geotextile to use (woven geotextile or non-woven geotextile) depends on the specific requirements and application scenario of the project. Here are some selection considerations:

Application needs: Determine the specific requirements of the project, such as whether greater strength and durability are required, better filtration and drainage performance, or whether flexibility and cost-effectiveness are more of a concern.

Soil conditions and topography: Consider the soil type, topographic characteristics and hydrology of the area where the project is located. For example, for areas with higher permeability requirements, non-woven geotextile may be more suitable.

Load and support requirements: If the project requires the use of geotextiles to withstand larger loads or provide higher support performance, it may generally be more appropriate to choose woven geotextile because it has higher tensile strength.

Installation and Construction Considerations: Select the appropriate type of geotextile considering the construction method and duration of the project. Non-woven geotextile is softer and easier to lay, while woven geotextile may be more suitable for more regular surfaces.

Economic cost: Consider the price, longevity and performance of both geotextiles and choose the type that fits your budget.

When making your choice, you can get more specific advice and guidance by conducting on-site testing, consulting with an engineer or geotextile supplier. Sometimes, engineering projects may require a combination of two types of geotextiles to meet different needs, which will result in comprehensive considerations and decisions based on the specific circumstances.

Woven and Non-Woven geotextiles each have their own advantages and are suitable for different types of engineering projects. When choosing the right geotextile, consider your project needs and specific conditions to ensure you choose the best material that meets your requirements.

Through the above analysis, you can better understand the advantages and applicability of the two geotextiles in different engineering scenarios, so as to make more informed choices in engineering projects.

897.webp)

942.webp)

237.webp)