Principle of Operation:

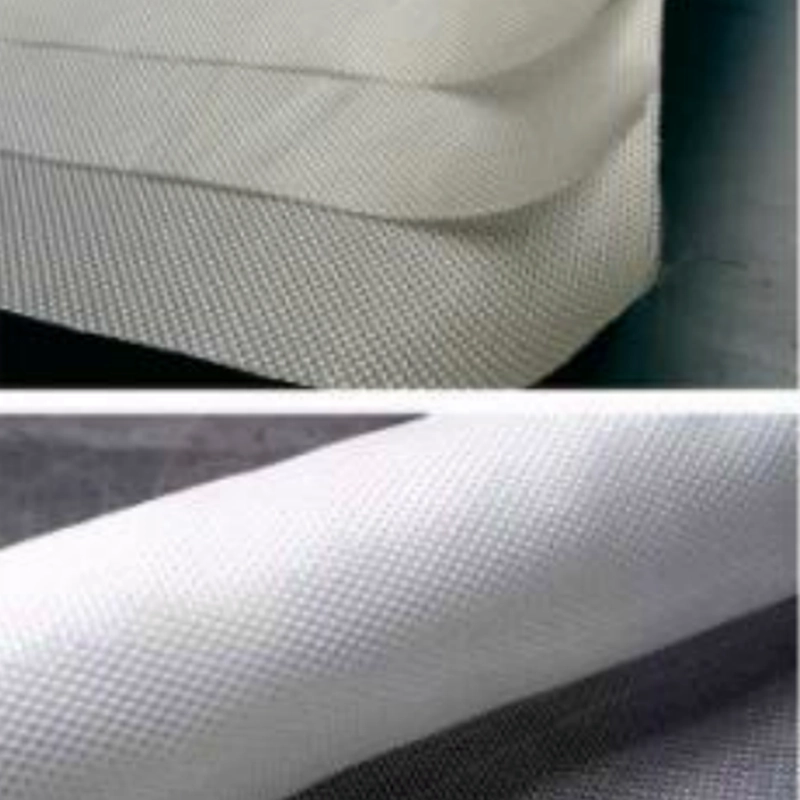

PET Filament PP Woven Geotextile stands as a pioneering solution leveraging the amalgamation of polyethylene terephthalate (PET) filament and polypropylene (PP) weaving techniques. This geotextile operates on the principle of reinforcement, introducing a resilient layer that reinforces steep slopes by distributing loads and enhancing soil stability. The woven structure provides excellent tensile strength, forming a robust barrier against soil erosion and slope degradation.

Efficacy and Benefits:

This specialized geotextile brings forth multifaceted efficacy in reinforcing steep slopes. By effectively interlocking with the soil, it mitigates erosion, thereby preventing displacement of soil particles and retaining slope integrity. Its permeable nature facilitates water drainage, reducing hydrostatic pressure and maintaining soil moisture levels conducive to vegetation growth. Furthermore, the geotextile's UV resistance ensures prolonged durability, even in harsh environmental conditions.

836407.webp)

Applications and Versatility:

The PET Filament PP Woven Geotextile finds versatile applications across various terrains and civil engineering projects. It serves as a pivotal component in infrastructure development, stabilizing embankments, controlling soil erosion in highway construction, and reinforcing retaining walls. Additionally, its adaptability to steep slopes in landscaping and environmental restoration projects highlights its significance in promoting sustainable land management practices.

917649.webp)

In summary, the PET Filament PP Woven Geotextile stands as a reliable and efficient solution in enhancing slope stability. Its innovative design, reinforced by the amalgamation of PET filament and PP weaving, offers a durable, eco-friendly, and cost-effective approach to safeguarding steep landscapes, ensuring long-term sustainability and resilience in diverse engineering and landscaping applications.

Place of Origin | Shandong,China |

Brand Name | Haoyang |

Geotextile Type | Woven Geotextiles |

Strength | 20-1000 |

Width | 1-6m |

Material | PP/PE |

Weight | 100-2200g GSM |

MOQ | 1000m2 |

Color | white,black |

Faq

Here is the translation of "PET Filament PP Woven Geotextile for Reinforced Steep Slopes FAQ":

What is PET Filament PP Woven Geotextile?

PET Filament PP Woven Geotextile is a geotextile fabric made from polyester (PET) filaments woven with polypropylene (PP). It is used in soil engineering to reinforce soil structures, reduce erosion, provide additional support, particularly on steep slopes or land surfaces.

In which scenarios is this geotextile used?

PET Filament PP Woven Geotextile is suitable for steep slopes or lands that require reinforcement. It can be used in projects like roads, railways, dams, reservoirs, land reclamation, among others, to enhance soil stability, reduce erosion, and provide a more reliable foundation.

What are its main advantages?

This product has high strength, corrosion resistance, durability, and excellent tensile properties. It effectively reinforces soil structures, prevents erosion, and offers reliable support, making steep slopes more stable.

How is this geotextile installed and used?

Installing this geotextile typically involves clearing and preparing the construction area, then correctly laying it in the desired location. Proper overlapping and fixation methods are essential to ensure effective coverage of the targeted area. Specific installation steps may vary depending on project requirements, so it's advisable to follow the manufacturer's installation guidelines.

What is the lifespan of this geotextile?

The lifespan of PET Filament PP Woven Geotextile depends on various factors, including environmental conditions, usage, and quality. Generally, high-quality geotextiles can be used for an extended period under appropriate conditions. However, regular inspections and maintenance are recommended to ensure its performance and effectiveness.

How to choose the appropriate specifications and models?

Choosing the right specifications and models often involves considering the requirements of the engineering project, including soil type, slope, project scale, among others. It is advisable to work with professional engineers or suppliers to select the appropriate specifications and models based on specific project needs.

235.webp)

487.webp)

383.webp)

466.webp)