Flat Yarn Woven Geotextile

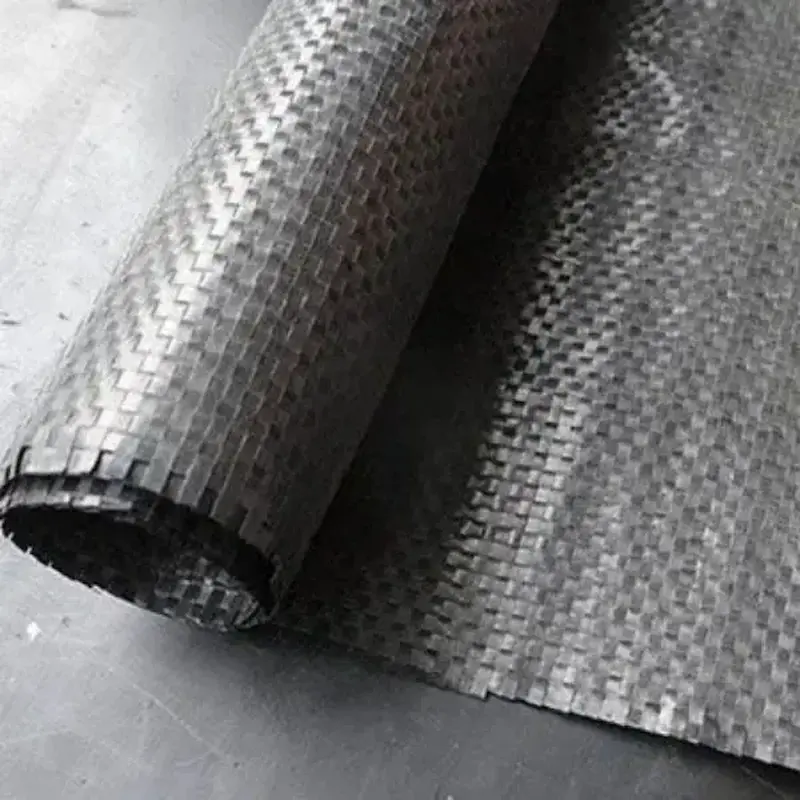

Woven Geotextile with Flat Yarn is made from polypropylene and polyethylene flat yarns. It consists of two parallel sets of yarns, one running along the length of the fabric (referred to as warp yarn) and the other arranged transversely (across the direction of fabric advancement, known as weft yarn). Using different weaving equipment and processes, the warp and weft yarns are interlaced to form a fabric. The thickness and density of the fabric can be varied according to the intended application. Generally, woven geotextiles are relatively thin and exhibit substantial tensile strength in both the warp and weft directions, with greater strength along the warp. They demonstrate excellent stability. This type of geotextile finds extensive applications in water conservancy, power plant, highway, aviation, and railway engineering projects.

Discover how Haoyang Environmental Co., Ltd. revolutionizes civil, hydraulic, and environmental engineering with our advanced Flat Yarn Woven Geotextile. Engineered to enhance durability and performance across various applications, our geotextile is a testament to innovation in material science and sustainable engineering solutions.

Characteristics

The plastic flat yarn woven geotextile is made from polyethylene or polypropylene materials,

offering several unique characteristics.

1, Firstly, it exhibits excellent corrosion resistance capable of withstanding the corrosive effects of chemicals, making it suitable for construction in various environmental conditions.

2, Secondly, it demonstrates outstanding abrasion resistance, maintaining its integrity under high tensile strength and being less prone to damage.

3, Additionally, it boasts high tensile strength, capable of withstanding significant pulling forces, effectively enhancing the stability of engineering structures.

It also features excellent permeability, preserving soil permeability and preventing the accumulation of moisture in the soil.

Applications

1, Erosion Control:

Flat yarn geotextiles are used to control soil erosion on slopes and embankments. They help stabilize the soil by preventing surface runoff and promoting vegetation growth.

2, Road Construction:

These geotextiles are often used in road construction to improve the performance and longevity of roadways. They provide separation between subgrade soil and overlying aggregate,

preventing mixing and maintaining the structural integrity of the road.

3, Retaining Walls:

Flat yarn geotextiles are employed in the construction of retaining walls to reinforce soil and prevent erosion. They enhance the stability of the structure by providing support to the soil.

4, Landfill Liners:

In landfill engineering, flat yarn geotextiles can be used as part of liner systems to contain waste materials and prevent the leaching of contaminants into the surrounding soil and groundwater.

5, Railway Track Stabilization:

Geotextiles are applied beneath railway tracks to improve the stability of the track bed, reduce settlement, and enhance overall performance.

6, Drainage Applications:

Flat yarn geotextiles are used in drainage systems to provide filtration and separation in various applications, such as underdrains, subsurface drainage, and behind retaining walls.

7, Slope Reinforcement:

Slopes and embankments can be reinforced with flat yarn geotextiles to prevent soil erosion, improve stability, and promote vegetation growth.

8, Dams and Reservoirs:

In dam construction and reservoir projects, geotextiles are employed to provide stability to soil structures, prevent erosion, and enhance the overall integrity of the water containment system.

Construction Method

Firstly, the construction site needs to be cleaned and leveled to ensure there are no debris and uneven surfaces.

Subsequently, lay the geotextile on the construction site, tightly bonding it with the ground to prevent slackness and movement.

Concurrently with the placement of the geotextile, appropriate anchoring measures should be taken to secure it to the ground, enhancing its tensile strength and stability. Regular inspection and maintenance of the geotextile are necessary, promptly repairing and replacing damaged sections to ensure its integrity and functionality.

Haoyang Invironmental's advantages

We are a Factory

Hao Yang Environment Co., Ltd. covers an area of over 230 acres, with more than 40,000 square meters of standardized industrial workshops. The company boasts over 26 modern production lines for geosynthetic materials and has a total annual production capacity of 73,500 tons.

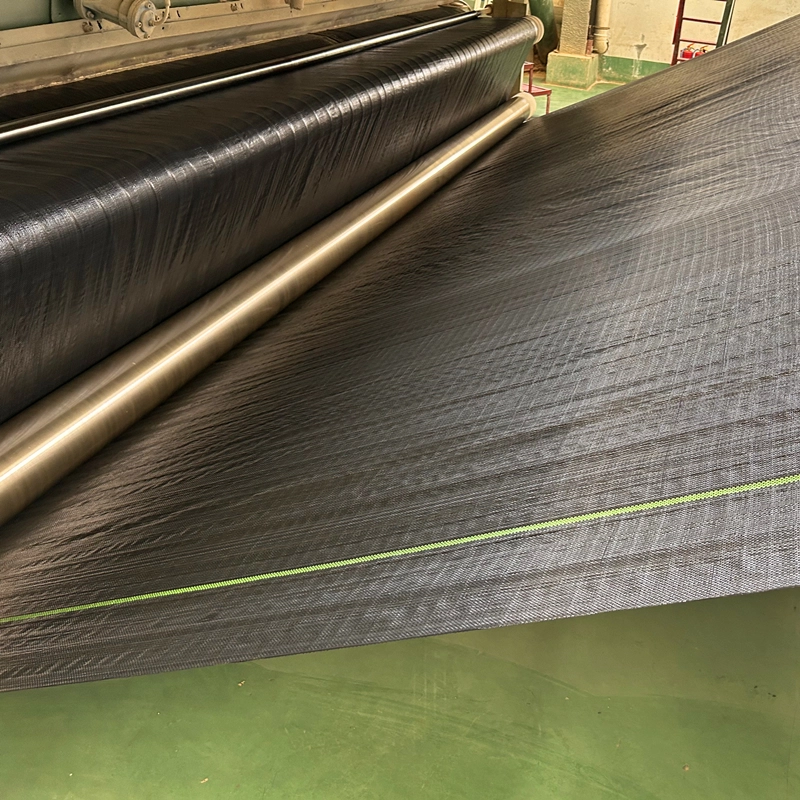

This is PP flat yarn woven geofabrics production line.

Certificate

Certified with ISO9001 Quality Management System and ISO14001 Environmental Management System.

509576.webp)

Laboratory

Both Indoor laboratory and outdoor laboratory

The establishment of an outdoor laboratory for geotechnical products provides a more authentic, comprehensive testing environment,

aiding in a better assessment of the performance and suitability of these products.

1,Real Environment Simulation: An outdoor laboratory provides a more realistic simulation of the actual outdoor conditions for geotechnical product testing.

976620.webp)

2,Natural Exposure and Weathering: The outdoor setting allows geotechnical products to be exposed to natural sunlight, rain, and other environmental factors, facilitating long-term testing to understand durability and stability.

3,Reduced Impact of Environmental Factors on Testing: Geotechnical products in an outdoor laboratory are directly influenced by natural elements such as temperature, humidity, and UV radiation, aiding in the accurate assessment of product performance under different climatic conditions.

(1)780857.webp)

4,Large-Scale Experiments: Outdoor laboratories typically offer sufficient space for large-scale geotechnical product experiments, allowing researchers to observe product behavior under various conditions more effectively.

5,Long-Term Monitoring: Outdoor laboratories enable long-term monitoring and observation to evaluate the extended performance and stability of geotechnical products, particularly crucial for products requiring sustained performance over several years or more.

6,Multi-Factor Testing: Outdoor laboratories allow for simultaneous consideration of multiple factors such as temperature, humidity, UV radiation, and wind, providing a more comprehensive and realistic testing environment.

If you are interested in any of geoproducts, please feel free to contact us, we are well aware of the importance of establishing a long-term, mutually beneficial, and win-win business partnership. We look forward to achieving the business goals of both parties through a collaborative and mutually beneficial approach,we will make every effort to meet your needs and provide you with excellent service.

Company Advantages

As a leader in geosynthetic material innovation, Haoyang Environmental Co., Ltd. brings unparalleled expertise and capabilities:

Comprehensive Service: From research and development to manufacturing and consulting, we offer end-to-end solutions tailored to project requirements.

Certified Excellence: ISO 9001, ISO 14001, and OHSAS 18001 certifications underscore our commitment to quality, safety, and environmental stewardship.

Proven Track Record: Recognized by national laboratories for our contributions to environmental protection and new materials engineering.

Explore the possibilities with Haoyang Environmental Co., Ltd. and integrate our Flat Yarn Woven Geotextile into your next engineering project. Contact us today to discuss how we can meet your specific needs and exceed your expectations.

FAQ

1, Q: What is flat yarn woven geotextile, and how does it differ from other types?

A: Flat yarn woven geotextile is a geosynthetic material made from flat tapes or yarns woven together. Its flat yarn structure sets it apart, providing enhanced tensile strength and filtration capabilities compared to non-woven alternatives. This design imparts a more structured and uniform composition.

2, Q: In which engineering applications are flat yarn woven geotextiles commonly used?

A: Flat yarn woven geotextiles find widespread use in civil, hydraulic, and environmental engineering projects. They are applied for soil structure reinforcement, erosion control on slopes, soil layer separation, and filtration in drainage systems. Additionally, they play a role in road construction, landfills, and various geotechnical applications.

3, Q: What are the key advantages of using flat yarn woven geotextiles?

A: The advantages include high tensile strength, excellent filtration properties, and durability. These geotextiles effectively stabilize soil, prevent erosion, and enhance the performance of geotechnical structures. The flat yarn design contributes to increased stability and resistance to deformation.

4, Q: How do flat yarn woven geotextiles contribute to environmental sustainability?

A: Flat yarn woven geotextiles contribute to environmental sustainability by controlling soil erosion, managing water drainage efficiently, and supporting the longevity of civil structures. They play a vital role in preventing soil degradation, promoting stable soil conditions, and contributing to overall environmental conservation.

5, Q: Are there specific guidelines for the installation and maintenance of flat yarn woven geotextiles?

A: Yes, proper installation and maintenance are crucial. Guidelines typically include site preparation, correct installation techniques, and periodic inspections. Adhering to manufacturer recommendations and industry standards is essential to maximize the benefits of flat yarn woven geotextiles in engineering projects. Regular inspections ensure that the geotextiles remain in good condition and continue to perform effectively over time.

503.webp)

759.webp)

482.webp)