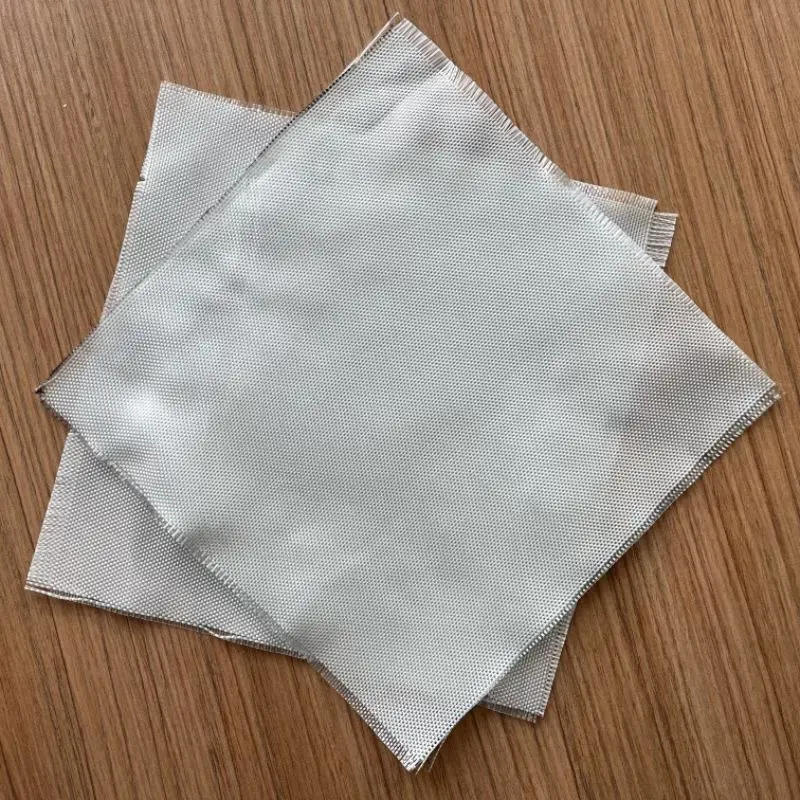

What is Plastic flat wire woven geotextile fabric?

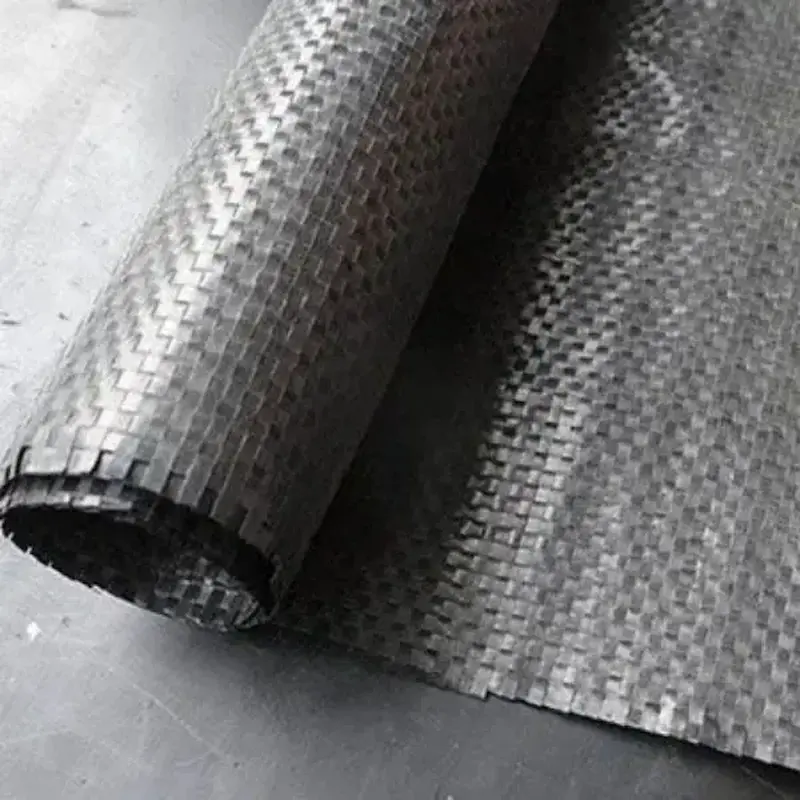

Plastic flat wire woven geotextile fabric is made from polypropylene and polyethylene flat filaments, with at least two sets of parallel yarns (or flat filaments). One set running along the longitudinal direction of the loom (direction of fabric progression) is called the warp yarn, and another set arranged transversely is known as the weft yarn. Using different weaving equipment and processes, the warp and weft yarns are interlaced to form a fabric. The thickness and density of the woven fabric can be adjusted based on its intended use. Generally, woven geotextile fabric is relatively thin and exhibits significant tensile strength in both the warp and weft directions (greater in the warp direction), showcasing excellent stability properties. The product features decide that It plays a very important role in filtration, separation, reinforcement, and drainage.

Product features

1, Woven Construction:

Woven structure with at least two sets of parallel yarns or flat filaments, creating a stable and robust fabric.

2, Versatility:

Adaptable to various applications in civil engineering, construction, and environmental projects.

3, Strength and Tensile Properties:

Exhibits significant tensile strength in both the warp and weft directions, with the ability to provide reinforcement.

4, Customizable Thickness and Density:

The thickness and density of the fabric can be adjusted to meet specific project requirements.

5, Stability Performance:

Demonstrates good stability properties, contributing to the overall integrity of the geotechnical structure.

6, UV Resistance (Optional):

Some products may feature UV resistance, enhancing durability and longevity when exposed to sunlight.

7, High Permeability:

Permeable structure allows water to pass through while retaining soil particles, making it suitable for drainage applications.

Corrosion Resistance and Erosion Control :

Resistant to corrosion, ensuring long-term performance in various environmental conditions. Effectively used for erosion control measures, preventing soil loss in areas prone to erosion.

8, Ease of Installation:

Easy to handle, cut, and install, facilitating efficient construction processes.

Plastic flat wire woven geotextile fabric's funtions: filtration, separation, reinforcement, and drainage

The plastic flat wire woven geotextile fabric's ability to perform filtration, separation, reinforcement, and drainage makes it a versatile and valuable material in geotechnical and civil engineering projects. Whether used in road construction, erosion control, foundation stabilization, or other applications, the geotextile fabric plays a vital role in ensuring the long-term performance.

1, Filtration:

The fabric acts as a filter, allowing water to pass through while retaining soil particles. This prevents soil erosion and maintains the integrity of the structure by filtering out fines.

2, Separation:

Used to separate different soil layers or materials, preventing the mixing of fine and coarse particles. This separation enhances the overall stability and performance of the construction project.

3, Reinforcement:

Provides reinforcement to soil structures, such as embankments, retaining walls, and slopes. The woven geotextile fabric adds tensile strength to the soil, reducing the risk of failure and improving overall stability.

4, Drainage:

Facilitates effective drainage by allowing water to flow through the fabric. This helps in preventing water accumulation, reducing hydrostatic pressure, and enhancing the overall drainage system's efficiency.

Applications

Plastic flat wire woven geotextile fabric finds diverse applications in various civil engineering and geotechnical projects, which highlight the versatility and effectiveness of plastic flat wire woven geotextile fabric in addressing various geotechnical challenges across different construction and environmental projects. Some common applications include:

1, Landfill Liners:

Utilized as a component in landfill liners to control water permeability and protect the environment from contamination.

2, Drainage Systems:

Incorporated into drainage systems to facilitate water drainage while retaining soil particles.

3, Slope Reinforcement:

Applied on slopes and embankments to reinforce soil, reduce surface erosion, and enhance stability.

4, Airport Runway Construction:

Employed in airport runway construction to improve soil strength and stability.

5, Subsurface Drainage:

Integrated into subsurface drainage systems to manage water flow and prevent soil saturation.

6, Railway Ballast Reinforcement:

Installed in railway ballast layers to improve stability and reduce track deformation.

7, Retaining Walls:

Utilized in the construction of retaining walls to enhance structural integrity and prevent soil erosion.

8, Road Construction:

Incorporated into road construction projects to improve the performance of the roadbed and prevent soil movement.

9, Coastal and Shoreline Protection:

Applied in coastal and shoreline protection projects to control erosion and stabilize the soil.

10, Erosion Control:

Used for erosion control measures in various landscapes to prevent soil erosion and protect the underlying terrain.

11, Reinforcement of Soft Soil:

Employed in areas with soft soil conditions to provide reinforcement and stability.

12, Land Reclamation:

Utilized in land reclamation projects to create stable and usable land from previously unstable or waterlogged areas.

13, Gabion Wall Construction:

Integrated into gabion wall structures to enhance their strength and prevent soil displacement.

14, Pipeline Trenches:

Used in the construction of pipeline trenches to provide support, prevent soil erosion, and control water permeability.

15, Green Roofs:

Incorporated into green roof systems to aid in drainage, soil retention, and vegetation support.

The versatility of plastic flat wire woven geotextile fabric makes it a valuable solution for filtration, separation, reinforcement, and drainage, contributing to the sustainability and durability of various infrastructure projects.

Processing

The production process of plastic flat wire woven geotextile fabric involves several steps. Here is a general overview of the process:

1, Raw Material Preparation:

The primary raw material for plastic flat wire woven geotextile fabric is polypropylene (PP).

PP pellets are melted to form a liquid polymer.

2, Extrusion:

The molten PP is extruded through a flat die to form flat tapes or sheets.

These flat tapes are then stretched to align the polymer molecules, increasing strength and durability.

3, Warp and Weft Yarn Formation:

The stretched tapes are wound onto bobbins to form the warp and weft yarns.

The warp yarns run in the longitudinal direction, while the weft yarns run transversely.

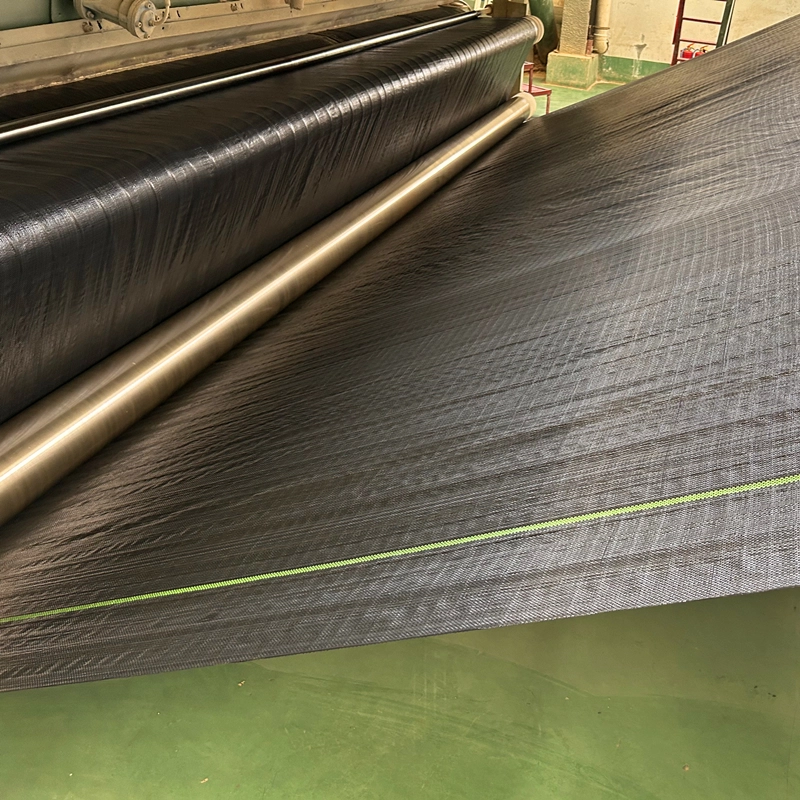

4, Circular Loom Weaving:

The warp and weft yarns are fed into a circular loom.

The circular loom interlaces the warp and weft yarns to create a woven fabric.

5, Fabric Coating (Optional):

The woven fabric may undergo a coating process for additional properties such as UV resistance, water resistance, or other specific characteristics.

6, Rolling and Cutting:

The finished woven geotextile fabric is rolled onto large spools.

It can be cut into specific dimensions according to the intended application.

7, Quality Control:

The manufactured geotextile fabric undergoes quality control checks to ensure it meets specified standards.

In conclusion, plastic flat wire woven geotextile fabric emerges as a versatile and indispensable component in the realm of construction and geotechnical engineering. Its filtration, separation, reinforcement, and drainage capabilities make it a valuable asset in ensuring the sustainability, stability, and durability of infrastructure projects. Our company produces high quality plastic flat wire woven geotextile fabric, please contact us if you need.

FAQ

1, What is the primary material used in plastic flat wire woven geotextile fabric?

Plastic flat wire woven geotextile fabric is primarily made from materials like polypropylene (PP) or polyethylene (PE) flat filaments, chosen for their durability and resistance to environmental conditions.

2, How does plastic flat wire woven geotextile fabric contribute to erosion control?

Plastic flat wire woven geotextile fabric prevents soil erosion by stabilizing the soil and reducing water runoff. Its woven structure acts as a barrier, retaining soil particles while allowing water to pass through.

3, What are the typical applications of plastic flat wire woven geotextile fabric in construction projects?

Plastic flat wire woven geotextile fabric is commonly used in road and railway construction for separation and stabilization, in retaining walls for reinforcement, and in drainage systems to facilitate water flow and prevent soil saturation.

4, How does the thickness and density of plastic flat wire woven geotextile fabric affect its performance?

The thickness and density of the fabric can be adjusted based on project requirements. Variations in these characteristics impact its effectiveness, with thicker and denser fabrics providing greater reinforcement and stability in geotechnical applications.

5, Is plastic flat wire woven geotextile fabric environmentally friendly?

Some products may incorporate recycled materials, contributing to environmental sustainability. However, the overall environmental friendliness depends on specific product compositions and manufacturing practices.

503.webp)

759.webp)

482.webp)