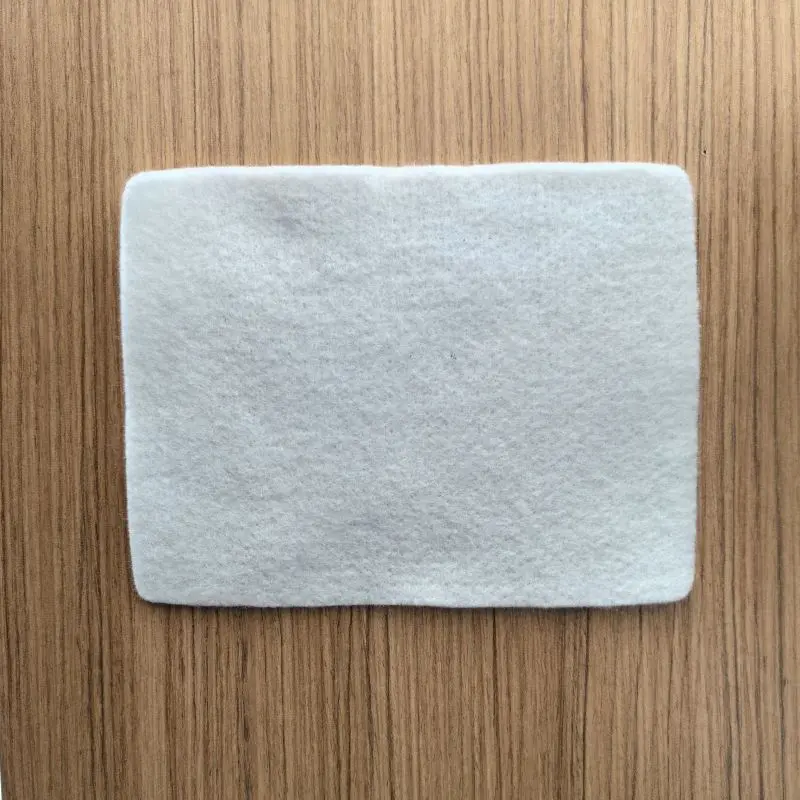

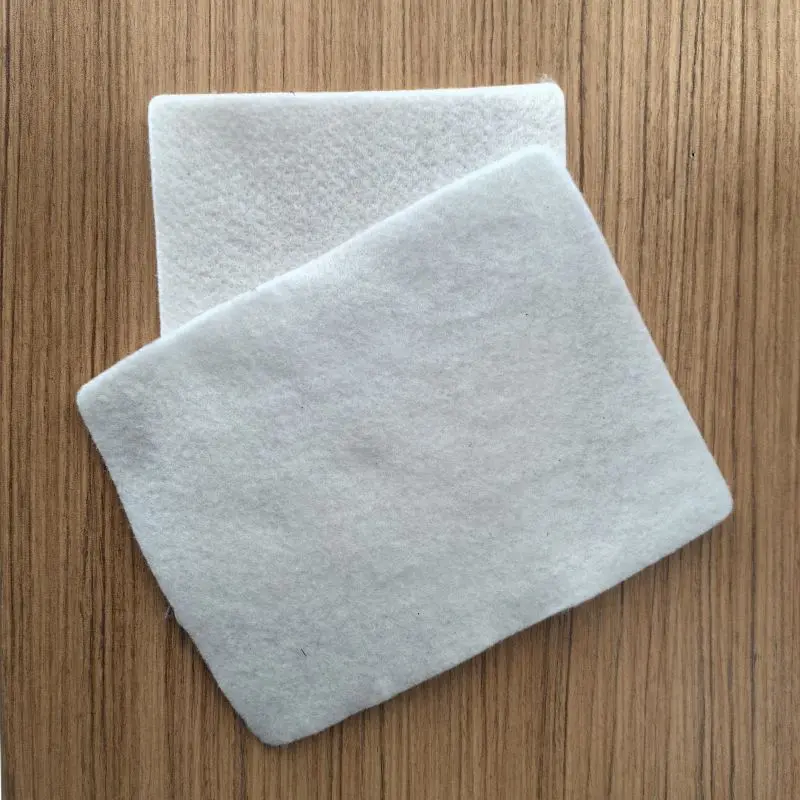

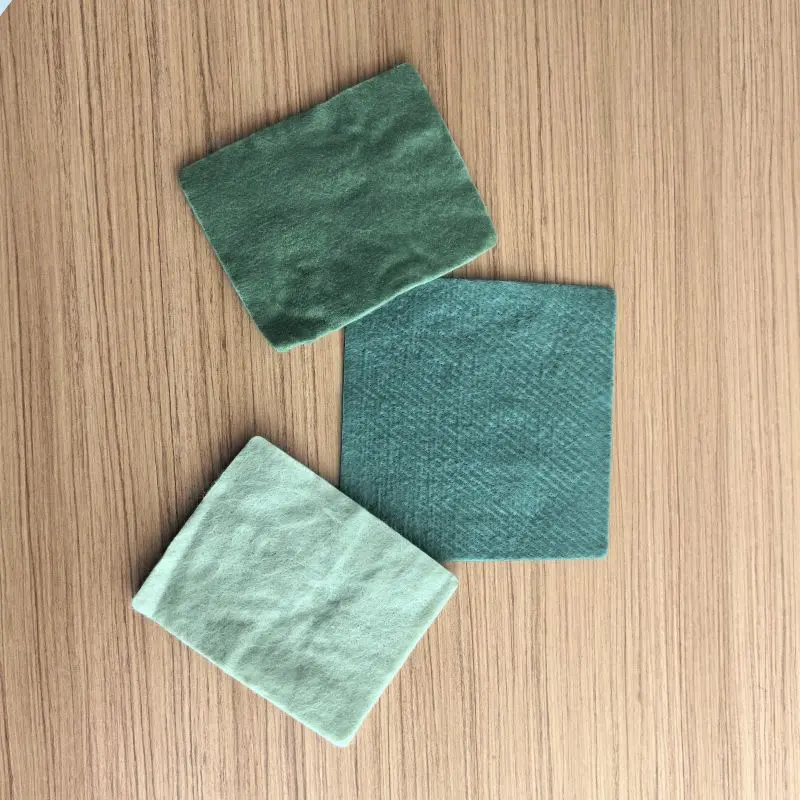

Staple Fiber Needle Punched Geofabrics

Staple or short fiber geotextile is usually made from polypropylene or polyester short fibers through processes such as opening, carding, mixing, web forming, and needle punching. This product boasts excellent properties such as superior permeability, filtration, and durability. It exhibits high tensile strength, tear resistance, and puncture strength in terms of mechanical performance. It can be widely used in various engineering applications, especially in road construction.

Are you searching for a reliable solution to bolster the longevity and stability of your road construction projects? Look no further than Haoyang Environmental Co., Ltd.'s groundbreaking Staple Fiber Non-woven Needle Punched Geotextile.

Specifications

items | tensile strength(kN/m) | elongation at break(%) | puncture strength(kN) | equivalent pore size | vertical permeability coefficient(cm/s) | tear strength(kN) | |

g/㎡ | 200 | ≥6.5 | 40-80 | ≥0.9 | 0.05-0.20 | kx(10-1-103) k=1.0-9.9 | ≥0.16 |

| 300 | ≥9.5 | ≥1.5 | ≥0.24 | ||||

| 400 | ≥12.5 | ≥2.1 | ≥0.33 | ||||

| 500 | ≥16.0 | ≥2.7 | ≥0.42 | ||||

| 600 | ≥19.0 | ≥3.2 | ≥0.46 | ||||

| 800 | ≥25.0 | ≥4.0 | ≥0.60 | ||||

Funtions of Staple Fiber Geotetxile in Raod Construntion

1,Separation and Filtration: It helps in separating different layers of soil or aggregate materials in the road construction process. By preventing the mixing of different materials, they enhance the stability and performance of the road structure. Additionally, they act as effective filters, allowing water to pass through while preventing the movement of fine particles, which can lead to the clogging of drainage systems.

2,Reinforcement: Staple fiber needle-punched geofabrics provide reinforcement to the road structure. They enhance the tensile strength of the soil and improve load distribution, reducing the potential for rutting and other forms of deformation. This reinforcement helps in extending the life and performance of the road.

966286.webp)

3,Permeability: These geofabrics offer controlled permeability, allowing water to pass through the fabric. This helps in preventing the buildup of water pressure within the road structure, reducing the risk of soil erosion and maintaining the stability of the roadbed.

4,Erosion Control: In road construction projects, particularly in areas prone to erosion, staple fiber needle-punched geofabrics play a crucial role in stabilizing the soil and preventing erosion. They provide a protective barrier that minimizes soil loss and maintains the integrity of the road structure.

5,Ease of Installation: Staple fiber needle-punched geofabrics are relatively easy to handle and install. Their lightweight nature facilitates quick and efficient installation, saving time and labor costs during road construction projects.

6,Cost-Effective: These geofabrics offer a cost-effective solution for road construction by providing durable reinforcement and erosion control. They contribute to the longevity of the road, reducing the need for frequent maintenance and repairs.

7,Versatility: Staple fiber needle-punched geofabrics are versatile and can be used in various soil conditions and road construction scenarios. Their adaptability makes them suitable for a wide range of applications in the construction industry.

Successful Case

The Jing-Shi High-Speed Railway project is a highly renowned railway endeavor in China. In accordance with the construction requirements of this project, we have supplied over 70,000 square meters of short-fiber needle-punched geotextile.

Problems It Enconters in This Project

In order to ensure the smooth operation of high-speed trains at high velocities, a significant concern in high-speed railway construction is the control of deformation in the subgrade. This deformation occurs in transition zones with abrupt changes, such as the junctions between bridge piers and the subgrade, tunnel exits, and other transitional segments. These variations lead to an uneven additional impact on the rapidly moving train wheels, causing discomfort in driving conditions. In severe cases, it can significantly reduce the lifespan of the structure and even pose safety risks. This type of ailment increases the expenses associated with costly maintenance and remediation.

Our Solutions

The use of geosynthetic materials in the transition zones of bridge-road segments can effectively overcome this issue. Polypropylene short fiber needle-punched geotextile has high strength, good elongation performance, a large deformation modulus, and resistance to acid, alkali, and corrosion. Combining short fiber needle-punched geotextile and geogrid can effectively address the challenges encountered in this projects.

213933.webp)

Attentions Should be Paid During Construction

1,Base Preparation: Ensure that the construction base is level, clean, and free of sharp objects or protrusions to prevent damage to the geotextile.

2,Laying Direction: The short fiber needle-punched geotextile should be laid correctly according to the design requirements, typically perpendicular to the direction of the railway line or as specified in the design.

3,Seam Treatment: For large coverage areas, proper seams should be established to ensure the overall integrity of the geotextile. Overlapping and fixation should be applied at seam locations.

4,Fixing Method: Use appropriate fixing methods such as ground nails, steel nails, weights, etc., to ensure the stability of the geotextile during construction and use.

5,Construction Temperature: Avoid laying the geotextile under extreme temperature conditions to prevent an impact on its performance. Protective measures should be taken during extremely cold or hot weather.

6,Joint Inspection and Repair: Regularly inspect the geotextile during installation, promptly repairing any damaged sections to ensure overall integrity and performance.

7,Fixing in Extreme Conditions: Avoid the presence of sharp objects in the geotextile installation area to prevent damage to the geotextile surface.

8,Moisture Management: Pay attention to moisture management during construction, avoiding laying the geotextile in damp conditions that could affect its performance.

Quality Control

We have obtained certification for ISO 9001 Quality Management System and ISO 14001 Environmental Management System.

610781.webp)

The quality of the product is paramountWe have our own laboratory, and for every batch of products, we preserve samples. Throughout the production process, workers from each shift extract samples for quality testing to ensure that the product meets the required standards.

596192.webp)

Your Partner in Progress

At Haoyang, we understand the challenges of modern infrastructure development. That's why we're not just selling a product; we're offering a partnership dedicated to your success. With our experienced technical R&D team and comprehensive support services, we stand ready to assist you at every stage of your project, from initial consultation to post-construction maintenance.

When it comes to road construction, don't compromise on quality or performance. Choose Haoyang Environmental Co., Ltd.'s Staple Fiber Non-woven Needle Punched Geotextile and experience the difference firsthand. Together, let's build a future of sustainable infrastructure that stands the test of time.

FAQ

Q1: Are you factory or trading company?

A: We are factory with ten years of experience. You can visit our factory online through video.

Q2: What’s your payment term?

A: 30% TT in advance and the balance before shipment or 100% Irrevocable L/C at sight.

Q3: How about the minimum order quantity?

A: We have no MOQ limited for the sample order and regular products.

The MOQ for special customized products is 5000 sqm.

Q4: How long is your delivery time?

A: It depends on the quantity of you quantity.

Usually, it takes 7-10 days upon we receive your deposit.

Q5: How can I get samples?

A: Sample can be sent by DHL or FedEx , etc.

Sample is free and freight collect. We promise we will definitely return the postage to you when we first cooperate.

Q6: Can you advise our pond liner installation and project design?

A: Welding machine is available for your installation.

If necessary, our welder can fly to your project site and install the pond liner. About the project design, we can also give you our rough advice.

503.webp)

759.webp)

509.webp)

769.webp)