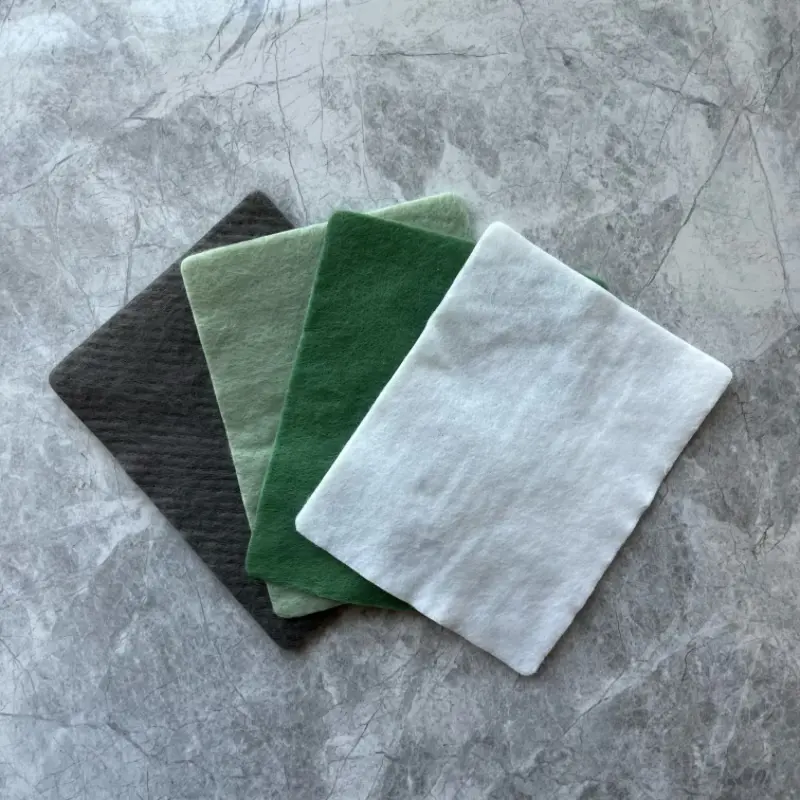

Filament needle punched nonwoven geofabric

Filament needle punched geofabrics are a type of non-woven geotextile material used in civil engineering and environmental applications. They are made by mechanically interlocking synthetic filaments or fibers through a process called needle punching, where barbed needles pierce and entangle the fibers to form a stable fabric structure. These geofabrics are typically composed of polyester or polypropylene materials, providing properties such as strength, durability, and resistance to biological and chemical degradation.

Product properties and applicaiton area

The properties of filament needle punched geofabrics and their application areas include:

1, Separation: These geofabrics effectively separate different soil layers, preventing the mixing of materials and maintaining the integrity of engineered structures. They are used in road construction, railways, and embankments.

2, Filtration: They allow water to pass through while retaining soil particles, preventing clogging of drainage systems and maintaining hydraulic efficiency. Applications include drainage systems, retaining walls, and erosion control projects.

3, Drainage: Filament needle punched geofabrics facilitate the efficient flow of water, reducing hydrostatic pressure and preventing waterlogging in various construction projects such as roads, sports fields, and landfills.

4, Reinforcement: These geofabrics enhance the stability and strength of soil structures by distributing loads and reducing settlement. They are used in applications such as reinforcement of retaining walls, slopes, and embankments.

5, Erosion Control: They stabilize soil surfaces, embankments, and riverbanks, preventing erosion caused by wind, water, or wave action. Common applications include erosion control blankets, coastal protection, and riverbank stabilization.

6, Chemical Resistance: Some geofabrics offer resistance to chemicals, acids, and alkalis, making them suitable for applications where exposure to aggressive substances is a concern, such as chemical containment areas and industrial sites.

7, UV Resistance: UV-stabilized geofabrics withstand prolonged exposure to sunlight without significant degradation, making them suitable for outdoor applications such as road construction, landscaping, and erosion control.

8, Permeability: Filament needle punched geofabrics maintain permeability under pressure, ensuring continuous water flow even in saturated conditions. They are used in drainage systems, filtration ponds, and land reclamation projects.

In summary, filament needle punched geofabrics offer a wide range of properties and applications, making them indispensable in modern civil engineering and environmental projects for their versatility, durability, and effectiveness.

TOP 20 advantages of filament needle punched geotextile fabric

Filament needle punched geofabric, also known as non-woven geotextile, offers numerous advantages in various civil engineering and environmental applications. Here are the top 20 advantages:

1, Separation: It prevents mixing of different soil layers, such as preventing fine particles from migrating into coarser layers.

2, Filtration: It allows water to pass through while retaining soil particles, preventing clogging of drainage systems.

3, Drainage: It facilitates efficient water flow, reducing hydrostatic pressure and preventing waterlogging.

4, Reinforcement: It enhances the stability and strength of soil structures by distributing loads and reducing settlement.

5, Erosion control: It prevents soil erosion by stabilizing slopes, embankments, and riverbanks.

6, Protection: It shields geomembranes, liners, and other vulnerable materials from punctures and abrasion.

7, Chemical resistance: Some geofabrics offer resistance to chemicals, acids, and alkalis, protecting underlying materials.

8, UV resistance: UV-stabilized geofabrics withstand prolonged exposure to sunlight without significant degradation.

9, Permeability: It maintains permeability under pressure, ensuring continuous water flow even in saturated conditions.

10, Flexibility: It conforms to irregular surfaces and subsurface contours, adapting to various project requirements.

11, Durability: High-quality geofabrics are resistant to biological degradation, ensuring long-term performance.

12, Cost-effectiveness: It reduces construction costs by minimizing the need for excavation, aggregate materials, and maintenance.

13, Easy installation: It is lightweight and easy to handle, allowing for quick and straightforward installation.

14, Environmentally friendly: It promotes sustainable construction practices by reducing the need for natural resources and minimizing environmental impact.

15, Versatility: It is suitable for a wide range of applications, including roads, railways, retaining walls, landfill liners, and erosion control projects.

16, Dimensional stability: It maintains its shape and properties under various environmental conditions, ensuring consistent performance over time.

17, Compatibility: It can be used in conjunction with other geosynthetic materials, such as geogrids and geomembranes, to achieve specific engineering goals.

18, Customization: Geofabrics are available in various thicknesses, strengths, and pore sizes to meet specific project requirements.

19, Regulatory compliance: It complies with industry standards and regulations, ensuring project quality and safety.

20, Proven performance: Geofabrics have a track record of successful use in numerous civil engineering projects worldwide, providing confidence in their performance and reliability.

These advantages make filament needle punched geofabric a valuable asset in modern construction and environmental protection projects.

897.webp)

942.webp)

237.webp)